Challenge

Lots of papers, spreadsheets and poor understanding of key performance drivers. The overall picture of the production line was not known and uncontrolled production stoppages had a negative impact. No real-time data was available to implement corrective measures and monitor their effectiveness.

Solution

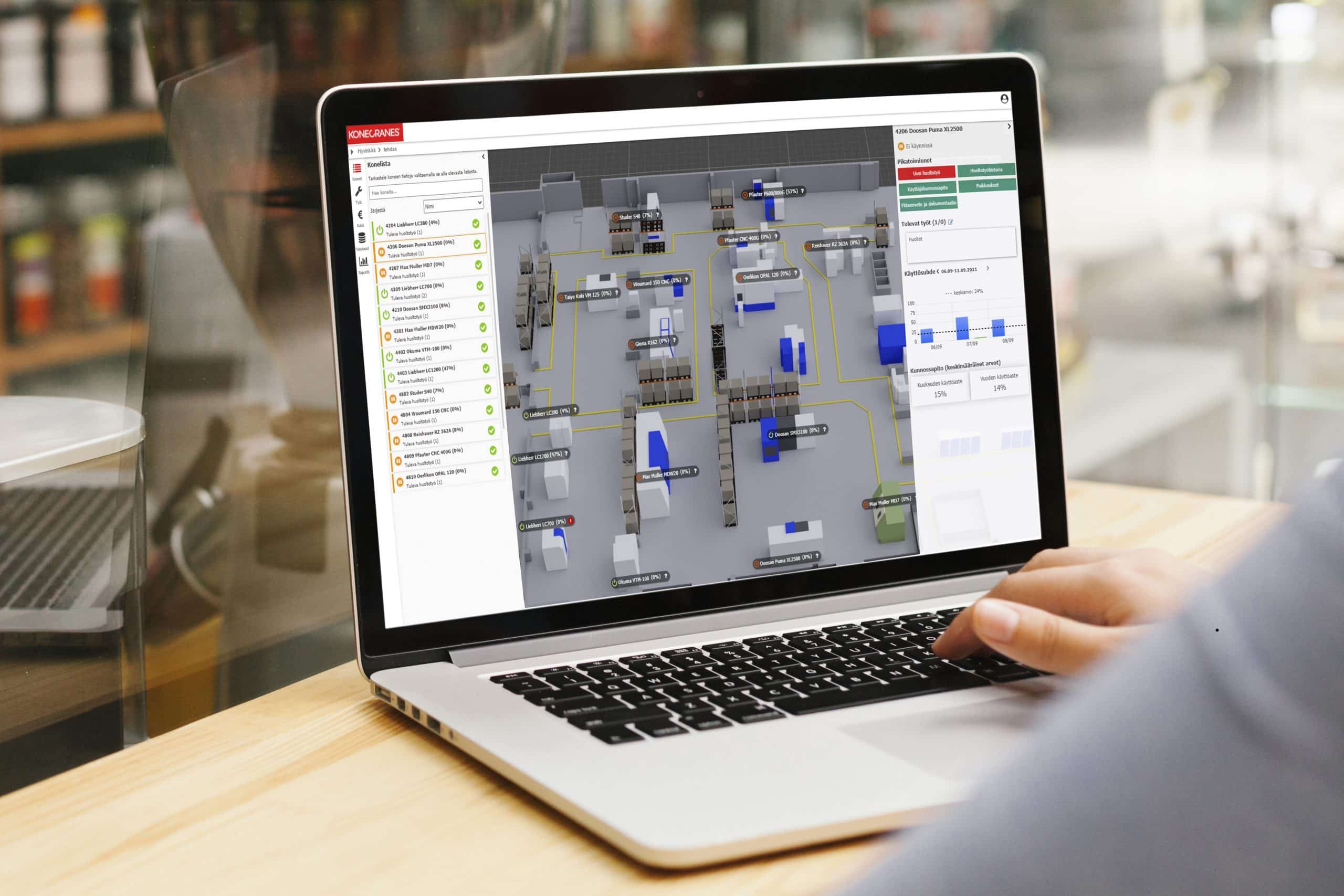

The Genius Core™ platform enabled the customer to design OEE meters for their entire production facility. The customer now has access to the entire factory in a convenient 3D modelling view, showing all production machines and equipment, as well as OEE metrics for each machine and for the entire production.

Key outcomes

As a result, the customer increased machine utilisation by up to 30%. Key performance losses were quantified and energy consumption was reduced by 10%. The number of large material losses was reduced, which has helped save thousands of euros every month. In addition, the customer saved 30-35% of time on daily production tasks, including maintenance and repair tasks, thanks to the features of the Genius Core™ platform.

All the information you need at one glance. One platform.

Want to know more about our solution for your organization? Please drop us a line and we’ll be in touch!