The ultimate guide to digital twin

What is a digital twin and how can it help my business? How is it different from other industrial software solutions? And how do these solutions work on a larger scale when we talk about Industry 4.0?

If you are looking for advice on how to transform your traditional factory into a smart environment using the latest key technologies of Industry 4.0, this page is for you. We have compiled different types and examples of Industry 4.0, the digital twin, and how to use it effectively to optimise your production. Feel free to scroll to the bottom of the page or click directly on the topic that interests you most.

- The digital twin and Industry 4.0

- What is a digital twin?

- What is the difference between the digital twin, ERP, MES and MRP?

- What is OEE, and how does it relate to the digital twin?

- What is OPC UA, and how does it relate to the digital twin?

- What are AR and VR , and how do they relate to the 3D digital twin?

- What is a 3D digital twin?

The digital twin and Industry 4.0

Let’s start by explaining what Industry 4.0 and the digital twin are, and how they are related – or not necessarily related, or mean the same thing. We provide answers to frequently asked questions.

What is Industry 4.0?

To understand Industry 4.0, we must first look at its historical context. The advent of Industry 4.0 generally dates back to the early 2010s, although it is important to note that its development has been gradual and influenced by previous technological advances. The concept of Industry 4.0 was first introduced in Germany in 2011, as part of the government’s high-tech strategy for 2020. The aim of the initiative was to modernise the country’s manufacturing industry and maintain its competitiveness on the world market.

The term “Industry 4.0” itself was coined during the initiative and received considerable attention. It builds on previous industrial revolutions, namely the mechanisation of production (Industry 1.0), the emergence of mass production through assembly lines (Industry 2.0) and the integration of computers and automation (Industry 3.0).

Although the term originated in Germany, the concept of Industry 4.0 quickly gained traction worldwide as other countries recognised its potential for economic growth and technological innovation. Governments, industry leaders and academic institutions around the world began to adopt the principles and explore ways to use these technologies in industrial development.

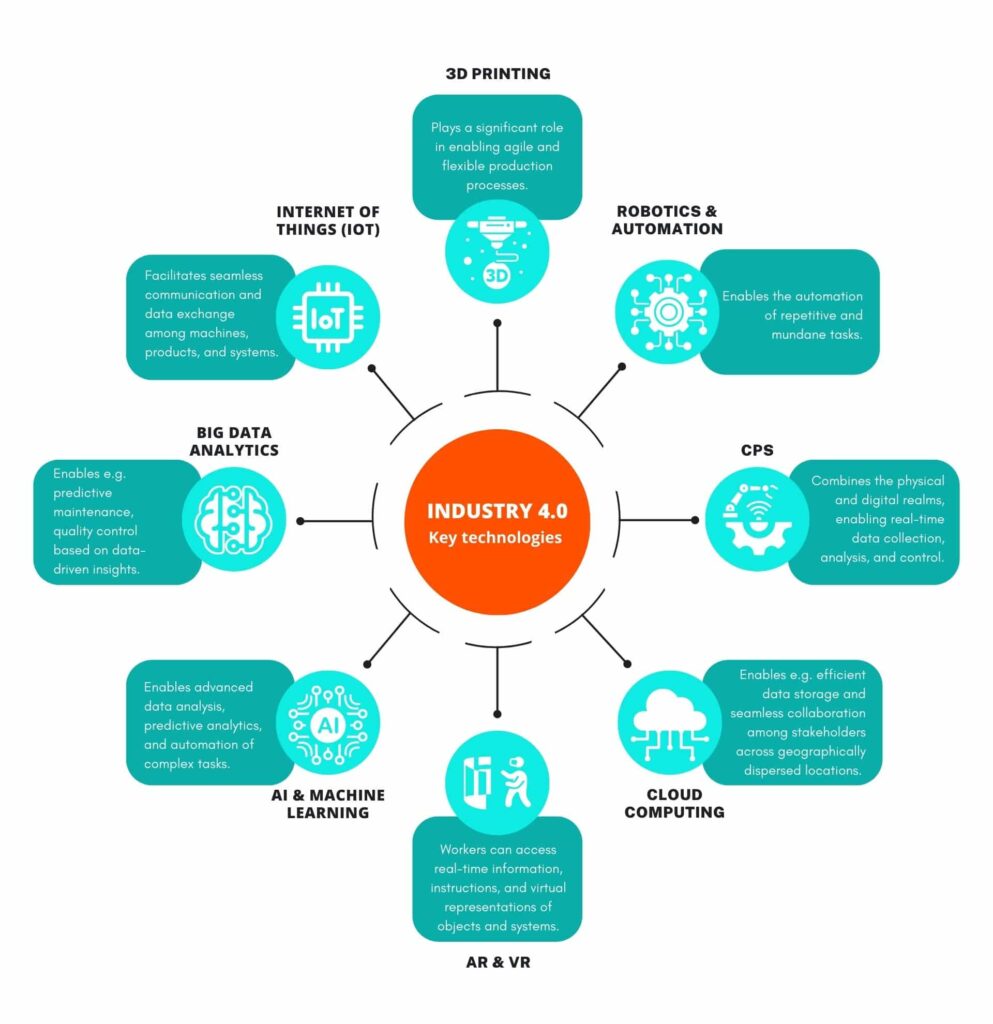

What are the key technologies in Industry 4.0?

Industry 4.0 includes a set of technologies that together will enable the transformation of traditional manufacturing industry into a more integrated and intelligent ecosystem.

The key technologies of Industry 4.0 are:

- Internet of Things (IoT): the Internet of Things refers to a network of interconnected devices embedded with sensors, software and connectivity features. In Industry 4.0, the Internet of Things will play a key role in facilitating seamless communication and information exchange between machines, products and systems. This interconnectivity enables real-time monitoring, remote control and optimisation of industrial processes, improving efficiency, productivity and responsiveness.

- Big Data Analytics: with the huge amount of data generated by IoT devices and interconnected systems, the field of big data analytics will become crucial. It includes techniques and tools for collecting, processing, analysing and managing actionable insights from large and complex data sets. Industry 4.0’s Big Data analytics enables predictive maintenance, quality control, production process optimisation and intelligent decision-making based on data-driven insights.

- Artificial Intelligence (AI) and Machine Learning: AI and machine learning techniques enable machines and systems to learn from data, identify patterns and make intelligent decisions without explicit programming. In Industry 4.0, AI algorithms and machine learning models will enable advanced data analysis, predictive analytics and automation of complex tasks. AI-based systems optimise production processes, facilitate predictive maintenance and support autonomous decision-making, increasing efficiency, productivity and innovation.

- Robotics and Automation: robotics and automation technologies have long been prevalent in industrial environments. However, Industry 4.0 will see them evolve significantly and take new forms. Robots work alongside human workers, sharing the same workspace and collaborating on tasks. Automation technologies based on advanced robotics enable the automation of repetitive and mundane tasks, freeing up human workers to focus on more complex and value-added tasks.

- Cyber-Physical Systems (CPS): cyber-physical systems form the backbone of Industry 4.0 by integrating physical components with software, sensors and connectivity. CPS connects the physical and digital worlds, enabling real-time data collection, analysis and management. This integration will foster the creation of smart factories and interconnected systems, where physical objects and processes are closely linked to digital representations and computational intelligence.

- Cloud computing: cloud computing provides a scalable and flexible infrastructure for storing, processing and accessing data and applications. In Industry 4.0, cloud computing will play an important role in handling the vast amounts of data generated by interconnected systems. It enables efficient data storage, the necessary computing resources and seamless collaboration between stakeholders from geographically dispersed locations.

- Additive Manufacturing (3D Printing): commonly known as 3D printing, additive manufacturing is revolutionising the way objects are created. It enables the creation of three-dimensional objects by adding material layer by layer based on digital models. 3D printing brings benefits such as rapid prototyping, customisation, decentralised production capacity and less waste. In Industry 4.0, 3D printing will play an important role in enabling agile and flexible production processes.

- Augmented Reality (AR) and Virtual Reality (VR): augmented reality and virtual reality technologies offer immersive and interactive experiences that combine the physical and digital worlds. In Industry 4.0, AR and VR offer applications for training, maintenance, visualisation and remote collaboration. They allow workers to access real-time information, instructions and virtual representations of objects and systems, improving productivity, safety and information transfer.

What is a digital twin?

A digital twin is a virtual copy or digital representation of a physical object, process or system. It is a dynamic and real-world model that mimics the behaviour, properties and interactions of its counterpart in real time.

The digital twin consists of three main components: the physical object or system itself, the corresponding virtual model and the link between the two. The virtual model is created using various data sources such as sensors, IoT devices, historical data and simulations. This virtual model reflects the characteristics, performance and behaviour of the physical object, allowing real-time monitoring, analysis and optimisation.

The main purpose of the digital twin is to bridge the gap between the physical and digital worlds and enable deeper understanding, monitoring and control of a physical object or system. It is a valuable tool for visualisation, analysis, simulation and forecasting.

What types of digital twins exist?

Within the digital twins, different types are defined according to their scope and purpose.

- Product Digital Twins: These digital twins represent individual physical products, such as machines, vehicles or consumer goods. The digital twins of products collect information on product design, performance and use. They allow manufacturers to simulate, analyse and optimise product functions, predict maintenance needs and improve overall performance/durability throughout the product lifecycle.

To this could be added the component/part twins, which are the basic unit of the digital twin. Digital twins modelling parts are roughly the same thing, but relate to slightly less important components. - Process Digital Twins: Process Digital Twins focus on modelling and simulating entire industrial processes or systems. They cover the interconnected components, machines, workflows and information flows associated with a particular process. Digital twin processes enable real-time process monitoring, analysis and optimisation, improving efficiency, reducing downtime and improving resource allocation.

- System Digital Twins: System Digital Twins cover larger scale systems or ecosystems, such as smart cities, transport networks or energy grids. These digital twins model and simulate the interaction and behaviour of different interconnected components in a system. The system’s digital twins provide insights for optimisation, predictive analysis and decision making to improve overall system performance, resilience and flexibility.

- Asset Digital Twins: Asset Digital Twins focus on individual components or resources within a wider system. They represent physical assets such as equipment, infrastructure or premises. Digital twins of assets enable real-time monitoring, performance analysis and predictive maintenance. Optimised asset utilisation and improved reliability are also available for cost-effective maintenance strategies.

- Facility Digital Twins: Facility Digital Twins specifically model and simulate buildings or physical spaces. They collect information on the building’s structural design, energy consumption, occupancy rates and maintenance needs. The digital twins in the building allow property managers to optimise energy use, improve space utilisation, streamline maintenance planning and ensure optimal comfort and safety for users.

- Human Digital Twins: Human Digital Twins is an emerging concept that aims to represent individuals in digital form. They integrate data from devices, health records and other sources to create a virtual personal model. The human digital twins have healthcare applications that enable personalised diagnostics, optimisation of treatment and monitoring of an individual’s health and well-being.

In addition, some companies have defined three main types of digital twin, more related to the manufacturing and process industries:

- Status twin: These are typically used for basic condition monitoring. Often in the form of dashboards and simple alarm systems. It primarily conveys the relevant operational parameters and is typically created using visualisation tools. The purpose of Status Twins is to provide a clear and concise overview of the current status and performance of a system or process. They allow easy monitoring and identification of key indicators.

- Operational twin: Provides a more comprehensive and detailed data set, primarily used by operators, reliability engineers and other decision-makers to support their decision-making. It is designed to be linked to a set of functions or work processes that allow users to interact with the twin and modify the action parameters within the allowed control features.

- Simulation twin: Harnesses a set of simulation or AI features to predict, forecast or provide insights into future operating states. It is a valuable tool for predictive maintenance and optimisation. Manufacturers can proactively identify potential problems and optimise operational efficiency. By using the predictive twin, organisations can make informed decisions to optimise the efficiency, maintenance planning and resource use of process plants.

What is the link between the digital twin and Industry 4.0?

The digital twin and Industry 4.0 are in a symbiotic relationship, with the digital twin acting as a key enabler and part of the wider Industry 4.0 paradigm.

First, the digital twin is the enabling technology of Industry 4.0. It enables the virtual representation and real-time monitoring of physical assets, systems and processes. These are in line with Industry 4.0 objectives to create interconnected, intelligent and data-driven systems for the industrial sector.

Second, the digital twins rely on real-time data from sensors, IoT devices and other sources to maintain accurate representations of physical entities. This real-time data collection and connectivity is in line with the fundamental principles of Industry 4.0, which emphasise the integration of IT, IoT and connectivity to enable seamless communication and information exchange in the industrial ecosystem.

Thirdly, both the digital twin and Industry 4.0 will promote data-driven decision-making. Digital twins generate massive amounts of data on physical assets and processes that can be analysed using advanced analytics, artificial intelligence and machine learning techniques. This data analysis facilitates real-time insights, predictive capabilities and informed decision-making, in line with Industry 4.0’s goals of process optimisation, efficiency and productivity improvements.

Digital twins enable virtual simulation, modelling and optimisation of physical assets and processes. This is in line with the objectives of Industry 4.0, which aim to optimise production processes, reduce downtime, improve resource utilisation and improve overall operational efficiency.

The digital twin will integrate with other key technologies related to Industry 4.0, such as the Internet of Things, mass data analytics, artificial intelligence and cloud computing. This integration will enable the seamless exchange and analysis of data, using advanced analytics and artificial intelligence to drive optimisation, automation and innovation in the industrial ecosystem.

Together, the digital twin and Industry 4.0 will facilitate the transformation of traditional production processes into intelligent, networked and digitalised systems. They will enable the creation of smart factories, digital supply chains and agile production processes, improving productivity, flexibility and competitiveness.

What are the main benefits of the digital twin?

- Digital twins provide a deeper understanding of physical assets, systems and processes by collecting real-time data and simulating behaviour. This enables informed decision-making, allowing stakeholders to make informed choices based on accurate and up-to-date views.

- By monitoring and analysing real-time data on physical assets, digital twins enable process optimisation, resource allocation and resource utilisation. They facilitate predictive maintenance, optimise workflows and improve operational efficiency, resulting in less downtime, higher productivity and cost savings.

- Digital twins enable virtual testing and simulation of product design, prototypes and manufacturing processes. This enables rapid prototyping, optimisation of product performance and accelerated innovation cycles.

- Through real-time monitoring and analysis, the digital twins can anticipate and detect potential maintenance problems, equipment failures or performance anomalies. This enables proactive maintenance planning, reducing unplanned downtime, optimising maintenance schedules and extending asset life.

- Digital twins facilitate risk assessment and analysis by simulating different scenarios and identifying potential security risks. They enable proactive analysis and optimisation of safety measures, ensuring a safer working environment and reducing the likelihood of accidents or incidents.

- By monitoring and analysing data on physical resources and processes, digital twins help organisations optimise resource use, energy consumption and material usage. This leads to improved sustainability, reduced waste and cost savings.

- Digital twins enable real-time monitoring and management of physical resources and processes, even at remote sites. This enables remote diagnosis, performance monitoring and remote management of operations. These can reduce the need for physical presence and enable efficient management of distributed resources.

- Digital twins facilitate collaboration and communication between stakeholders by providing a common digital platform to access and analyse real-time data. This fosters collaboration between teams, departments and even organisations, enabling effective decision-making and problem-solving.

Examples of how the digital twin is used

In the manufacturing industry, a digital twin can represent a machine, a production line or an entire factory. By simulating and analysing the virtual model, manufacturers can optimise production processes, perform predictive maintenance and identify areas for improvement, ultimately increasing efficiency, reducing downtime and saving costs. The digital twins will also find data on smart cities, transport systems, energy grids and more.

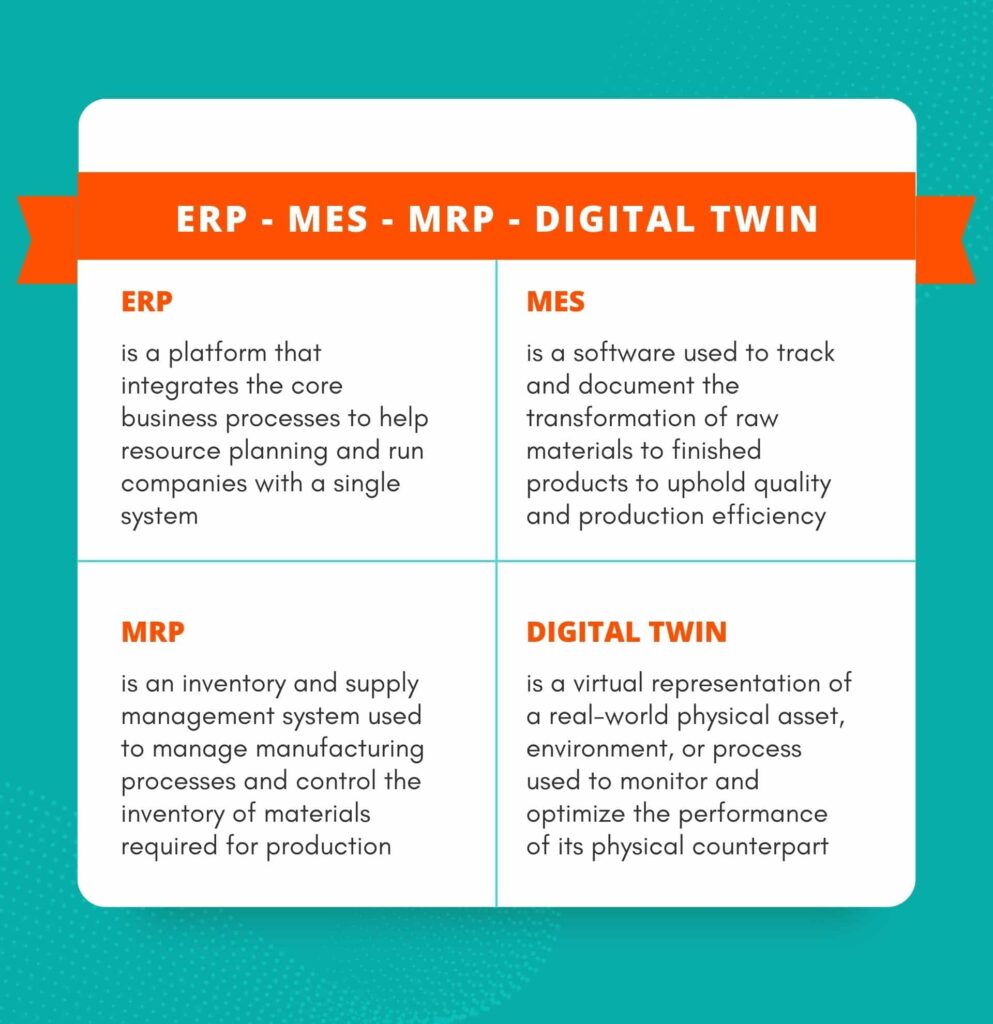

What is the difference between the digital twin, ERP, MES and MRP?

Now that we have gone through the concept of the digital twin, its different types, and how it relates to Industry 4.0, we can dive deeper into Industry 4.0. Next, we present the industry’s most popular system solutions on the market today.

“What is ERP, MES, MRP and how do they relate to the Digital Twin?” “Do I need a Digital Twin if there is MES?” “Is it enough to implement only ERP without Digital Twin?”

The above questions are often raised by the employees and management of industrial companies when the goal is to transform the factory from a traditional one to a smart factory. That’s why we’ve compiled a list of industrial system solutions with explanations.

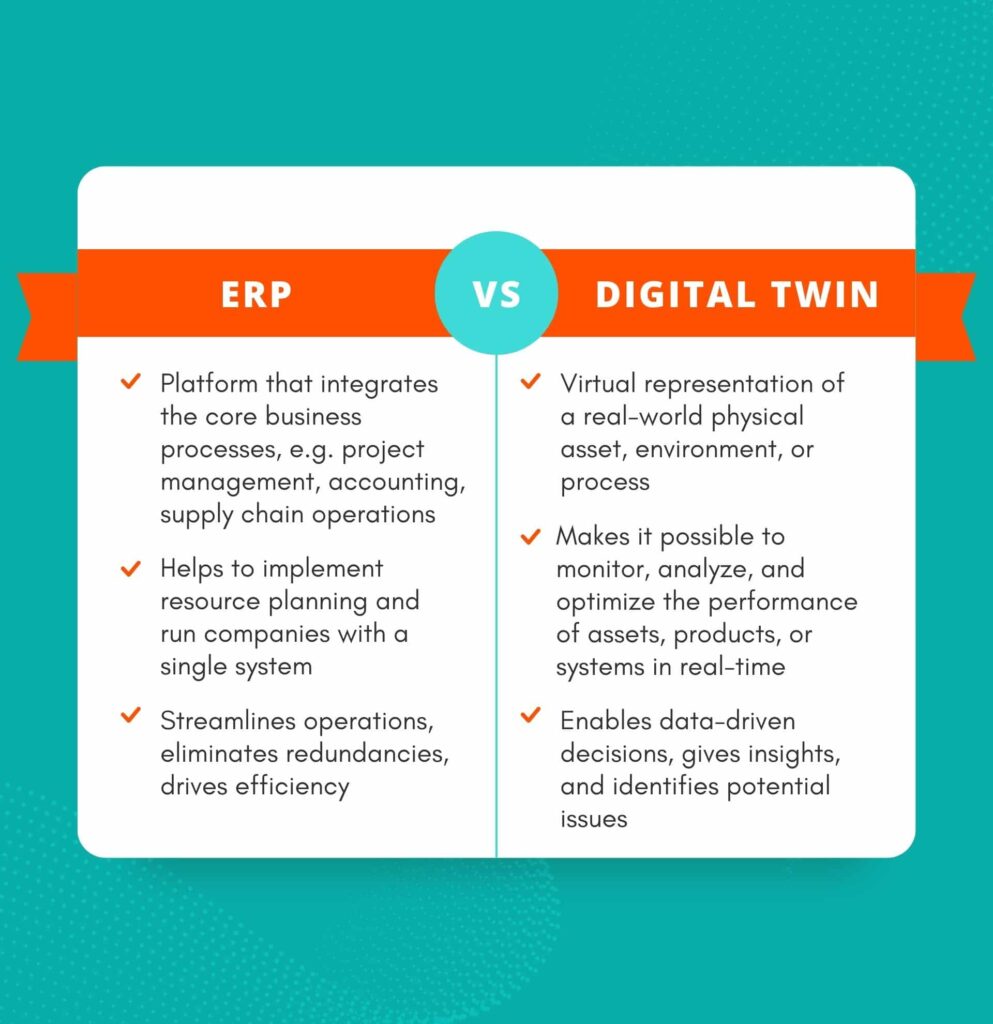

What is the difference between ERP and the digital twin?

ERP stands for “Enterprise Resource Planning”, which refers to a comprehensive software system into which the various business functions and processes of an organisation can be integrated.

ERP is designed to facilitate the flow of information and resources between different departments within a company. It acts as a central hub where information from different business functions, such as finance, HR, manufacturing, supply chain management and customer management, is consolidated and managed in a unified way.

The primary objective of implementing an ERP system is to streamline and optimise business processes and improve operational efficiency and decision-making. By combining data from different areas, ERP provides real-time visibility into key performance indicators, allowing managers to make informed decisions based on accurate and timely information.

An ERP system typically consists of a central database and a set of interconnected modules or applications that serve specific departments. These modules can include finance and accounting, human resources, inventory management, procurement, sales and marketing, production planning and much more. The modules are designed to meet the specific requirements of each department, while seamlessly sharing information and facilitating communication across the organisation.

ERP systems offer organisations numerous benefits, such as improved productivity, lower operating costs, high quality customer service, streamlined supply chain management and improved data accuracy. By automating routine tasks and providing a holistic view of the business, ERP helps organisations streamline operations, eliminate duplication and achieve greater efficiency.

A digital twin is a digital copy or virtual representation of a physical object, system or process. As a concept, the digital twin has gained significant traction in recent years, particularly in the context of Industry 4.0 and the Internet of Things (IoT). The digital twin is created by collecting real-time data from sensors, devices or systems and using advanced technologies such as artificial intelligence (AI) and machine learning (ML) to simulate and model the behaviour, properties and performance of a physical counterpart.

While ERP focuses on the integration and management of an organisation’s data and processes, the digital twin goes further by providing a dynamic and interactive virtual model of the physical entity. It allows organisations to monitor, analyse and optimise the performance of their assets, products or systems in real time. By harnessing data from the physical world and running simulations or predictive analytics, the digital twin enables organisations to make informed decisions, lead with data and identify potential problems before they happen in the physical world.

Essentially, ERP is primarily concerned with the management of business processes and data within an organisation, while the digital twin is a technological concept that represents a virtual replica of a physical entity, with features that allow real-time monitoring, analysis and optimisation of production.

Finally, however, it is worth noting that there may be points of intersection between ERP and Digital Twin technologies. Some ERP systems can use the principles of the digital twin by integrating real-time data from IoT devices or sensors to provide better visibility and decision-making capabilities. Similarly, Digital Twin models can use data from ERP systems to simulate and analyse the impact of different business processes or changes on the physical entity.

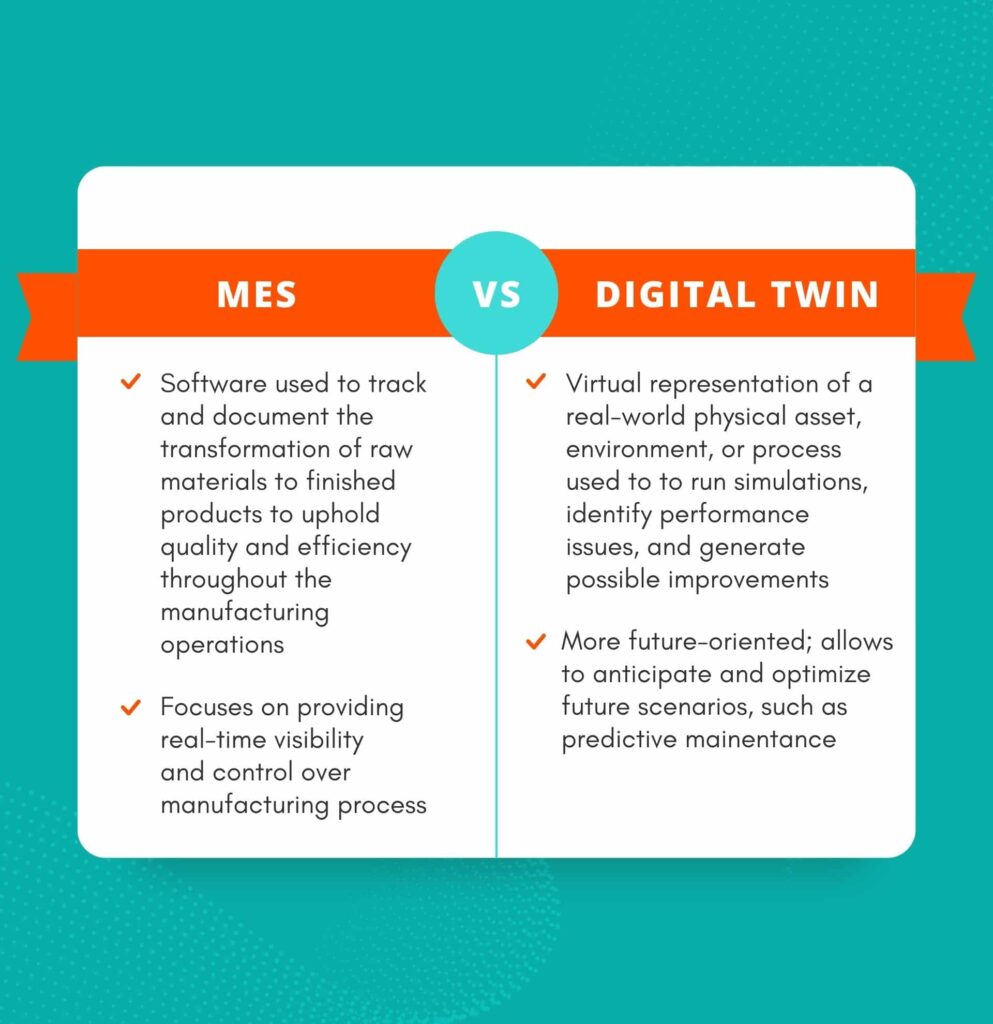

What is the difference between an MES and a digital twin?

MES, which stands for “Manufacturing Execution Systems,” is a critical part of modern manufacturing processes. MES is a software-based system that provides real-time visibility and control of various manufacturing activities in the factory itself. It acts as a bridge between the ERP system, which manages high-level planning and resource allocation, and the actual implementation of production processes.

The primary objective of MES is to control, monitor and optimise manufacturing operations in real time. It collects data from various sources, such as machines, sensors, operators and other systems, and provides comprehensive information on the status, performance and quality of production and machinery.

MES systems typically offer a wide range of functions, such as:

- Production scheduling and dispatching: the MES enables efficient scheduling and sequencing of production orders based on factors such as available resources, machine availability and production priorities. It ensures that the right jobs are assigned to the right workstations or machines.

- Production floor management: MES systems monitor and control manufacturing activities in the production floor. This includes monitoring the progress of production orders, storing and managing inventory and materials, and providing real-time status updates.

- Data collection and management: the MES collects and analyses real-time data from machines, sensors and users. It provides a view of key performance indicators (KPIs) such as machine utilisation, cycle times, downtime and quality metrics. This information will help identify bottlenecks, inefficiencies and areas for improvement.

- Quality control: MES systems facilitate quality control by monitoring standard operating procedures, collecting information on product quality, performing inspections and tests, and producing quality reports. It helps ensure that products meet the required specifications and standards.

- Traceability and genealogy: the MES enables the tracking and tracing of materials, components and processes throughout the manufacturing lifecycle. It provides a complete record of the genealogy of each product, including its origin, manufacturing stages and related information. This is particularly important in sectors with strict regulatory requirements, or dealing with complex or highly regulated products.

Integrated with other systems such as ERP, inventory management and quality control systems, MES improves production efficiency, reduces errors, improves product quality and enables faster decision-making on the shop floor.

Next, let’s look at the differences between MES and the digital twin:

- Scope and focus: the MES focuses primarily on the management and optimisation of manufacturing operations on the shop floor. It collects real-time data, monitors processes and sheds light on operational performance. The digital twin, on the other hand, extends beyond production to cover the entire life cycle of physical resources or systems. It models and simulates the behaviour, operation and performance of resources, enabling real-time monitoring, analysis and anticipation of potential problems.

- Purpose: MES systems are designed to improve production efficiency, optimise manufacturing operations and improve quality control in real time. Therefore, the functions they offer focus on, for example, production scheduling and control, data collection and quality management. The digital twin, on the other hand, focuses on creating a virtual replica of a physical device or system for various purposes such as design optimisation, predictive maintenance, performance analysis and simulation-based testing.

- Leveraging data: the MES primarily uses real-time data from sensors, machines and operators to monitor and control manufacturing operations. It collects data related to production, quality indicators and machine use. The digital twin also uses real-time data, but goes beyond MES by integrating data from different sources throughout the lifecycle of the resource. This includes information on design, manufacturing, operation, maintenance and even customer feedback. The digital twin uses this comprehensive data set to analyse, simulate and optimise the performance of a physical resource.

- Timeframe: the MES focuses on providing real-time visibility and control of manufacturing operations. It provides an overview of the current state of production processes and enables timely decision-making. Instead, the digital twin also offers a view into the future. It uses real-time and historical data to simulate and predict the behaviour and performance of a device or system. The digital twin allows organisations to predict and optimise future scenarios, such as predictive maintenance or performance optimisation, based on predictions from the virtual model.

In summary, the MES and the digital twin represent distinct concepts in manufacturing. MES focuses on real-time monitoring and control of manufacturing operations, while the digital twin goes further by creating a virtual replica of a physical device or system for simulation, analysis and optimisation throughout its lifecycle. Both concepts offer unique advantages and ways to apply them to improve manufacturing efficiency, quality and decision-making.

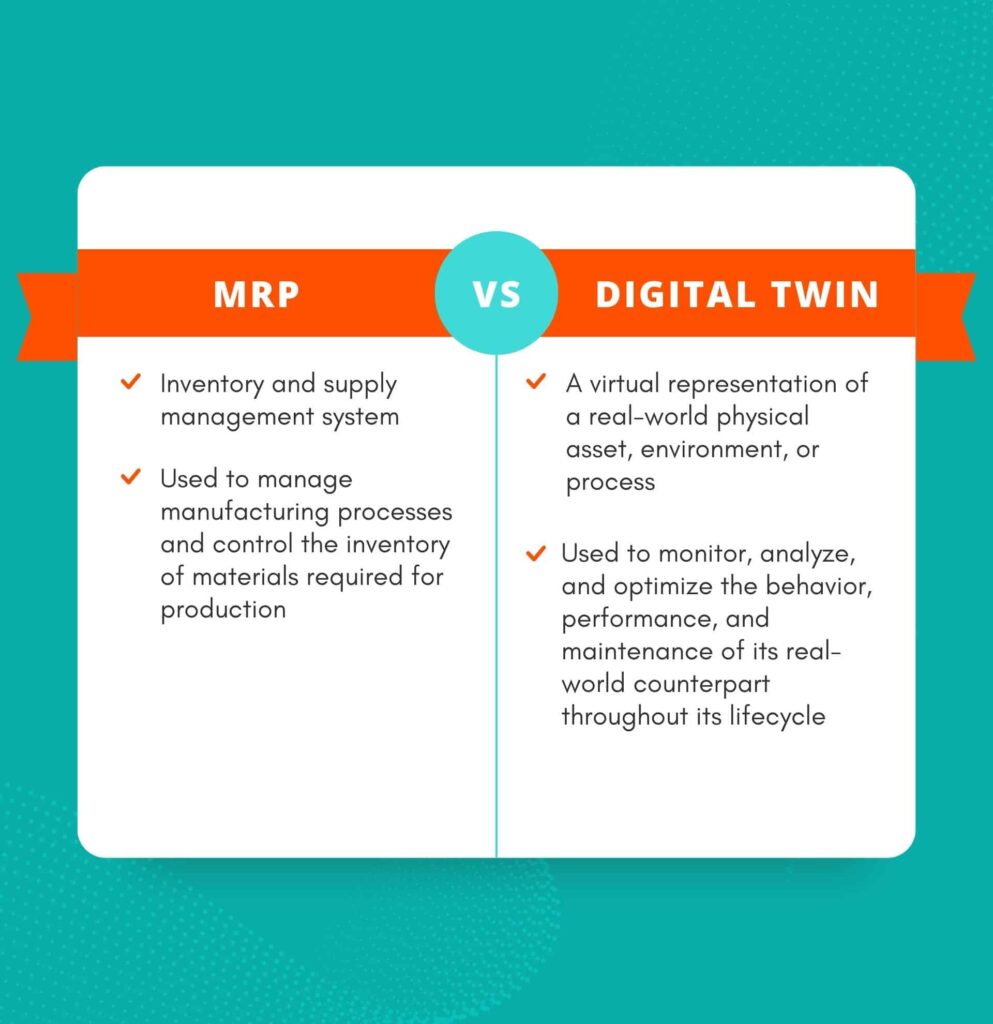

What is the difference between MRP and digital twin?

Material Requirements Planning, often called MRP, is a methodical approach or system used to effectively manage and control the raw materials, components and sub-assemblies required for inventory and finished product manufacturing.

The primary objective of MRP is to ensure that the necessary materials are available at the right time, in the right quantities and at the right place to meet the production schedule. MRP analyses the demand for the final product, taking into account product structure, lead times and component stock levels, and creates a plan that structures the requirements for each material component.

A needs assessment typically proceeds through the following steps:

- Product structure (BOM): a product structure is a hierarchical list of all components and sub-assemblies needed to manufacture a final product. It determines the proportions and quantities of materials needed at each level of the product structure.

- Master Production Schedule (MPS): the MPS outlines a production plan for finished goods, indicating the quantities and delivery dates needed to meet customer demand. MPS is the main input for MRP calculations.

- Inventory status: the MRP is based on accurate information on current stock levels of raw materials and components. This includes information on products available from stock, products ordered but not yet dispatched and any open production orders.

- MRP calculations: MRP performs calculations based on product structure, MPS and warehouse space to determine the quantity and timing of material requirements. It takes into account lead times, safety stock levels and order quantities to create a detailed plan showing when and how much of each material should be ordered or produced.

- Purchase and production orders: the end result of the demand calculation is the creation of either purchase orders or production orders for the materials to be purchased or manufactured. These orders are created based on planned requirements and are designed to maintain an optimal stock level to support the production schedule.

MRP enables organisations to manage product stock levels effectively, reduce stock-outs and overstocking, and improve overall production planning. It enables better coordination between different departments, such as production, procurement and inventory management, by providing a structured approach to material planning.

Next, let’s look at the differences between MRP and the digital twin:

- Purpose and scope: the MRP focuses primarily on the management and control of the inventory of materials needed for production. It aims to ensure that the right materials are available in the right quantities and at the right time to meet production schedules. Digital twin is a broader concept that covers the virtual representation and simulation of a physical device or system. It goes beyond material design and enables organisations to monitor, analyse and optimise the behaviour, performance and maintenance of manufacturing equipment throughout its lifecycle.

- Use of data: the MRP relies on data such as demand forecasts, product structure and stock levels to plan the materials needed for manufacturing and make procurement plans. It deals primarily with historical and forecast data on the availability and demand for materials. A digital twin, on the other hand, uses real-time data from sensors, devices or systems to create a virtual model that mimics the behaviour and performance of a physical device or system. It uses this real-time data to monitor and optimise equipment performance, predict maintenance needs and simulate different scenarios to improve decision-making.

- Timeframe: MRP typically focuses on planning and implementing material requirements in a timely manner to support production schedules. It deals primarily with the present and the near future. The digital twin looks further into the future, using real-time and historical data to simulate and predict device behaviour and performance. It allows organisations to anticipate and optimise future scenarios, such as predictive maintenance, performance optimisation or process improvement, based on predictions from the virtual model.

- Application: MRP is primarily used in manufacturing and production planning to manage material inventory and procurement. It is closely linked to the operational activities in the store. The digital twin is being applied more widely across industries and sectors. It can be used in areas such as product design, development, maintenance and resource management, allowing organisations to optimise the lifecycle performance of equipment or systems.

MRP focuses on ensuring adherence to production schedules by focusing on the planning, procurement and availability of materials, while the digital twin provides a real-time view to monitor, analyse and optimise equipment or systems throughout their lifecycle.

What is the difference between ERP, MES, MRP and the digital twin?

To summarise the differences between the systems:

The systems described above can also interact and complement each other in some cases. For example, MRP accounting can be integrated with ERP, MES can be connected to both ERP and MRP systems for real-time data exchange, and Digital Twin models can use ERP, MRP and MES data for simulation and analysis.

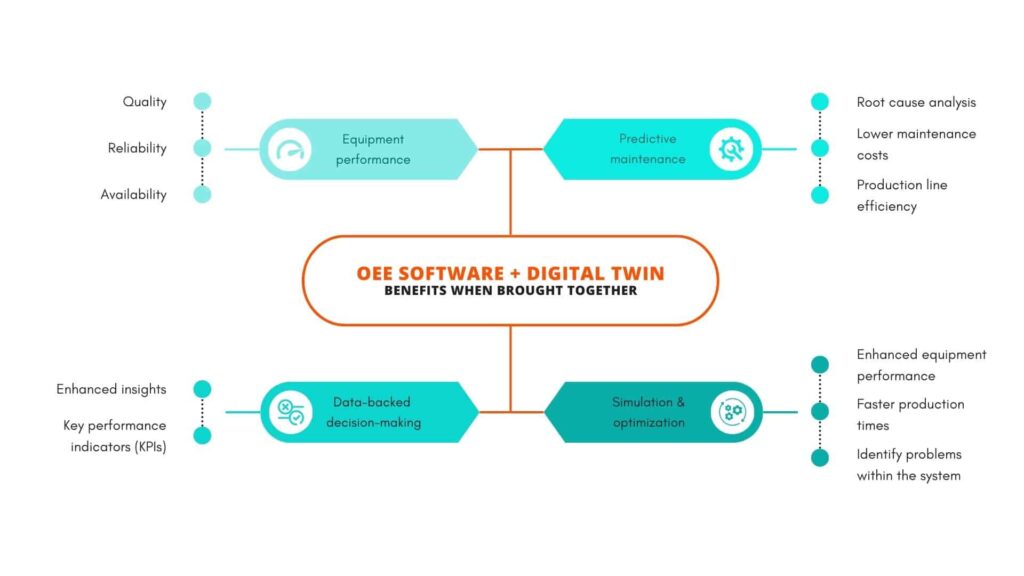

What is OEE, and how does it relate to the digital twin?

OEE (Overall Equipment Efficiency) software is a tool used to measure and improve the efficiency and performance of production equipment. It provides information on how efficiently a machine or production line is being used and how effectively it is operating.

OEE software usually includes features and functions that help to collect, analyse and interpret data related to the performance of the device. These tools help monitor a range of metrics, such as availability, performance and quality.

Below are some common features of the OEE software:

- Data collection: the OEE software collects real-time data from sensors, machines or manual inputs to measure and monitor equipment performance. This includes information on downtime, process throughput, production volumes and quality.

- Reporting and analysis: the OEE software provides detailed reports and analysis on key performance indicators (KPIs). They allow users to identify bottlenecks, analyse trends and find processes to improve. It can include features such as summaries, charts and visualisations that present information in a user-friendly format.

- Performance monitoring: the OEE software tracks and monitors metrics to determine the overall performance of the device. These measures include availability (uptime), performance efficiency (actual vs. target lead times) and quality (errors). Metrics help identify areas where performance can be optimised.

- Root cause analysis: the OEE software can provide tools to analyse and identify the root causes of equipment downtime, performance degradation or quality problems. This will help manufacturers to identify underlying problems and take corrective action.

- Integrations: the OEE software can be integrated with other manufacturing systems, such as ERP or MES (Manufacturing Execution Systems), to provide data. This gives a comprehensive picture of the production processes.

When integrated with Digital Twin technology, OEE software creates the opportunity to improve equipment performance through simulation and optimisation. This allows manufacturers to monitor and analyse equipment performance in real time, simulate different scenarios and proactively detect potential problems or periods of inefficiency. This integration will enable manufacturers to make informed decisions, optimise equipment performance and ensure a more efficient manufacturing environment.

What is OPC UA, and how does it relate to the digital twin?

OPC UA, which stands for Object Linking and Embedding for Process Control Unified Architecture, is a widely used communication protocol for industrial automation and control systems.

OPC UA software provides a framework for secure and reliable data transfer between different devices, systems and software applications in industrial environments. It provides a standardised and functional communication tool that ensures seamless connectivity and information exchange between different platforms and suppliers.

This software uses a client-server model, where client applications can request and retrieve data from servers that host the desired data. OPC UA offers a wealth of features and functionality to facilitate the transfer of real-time process data. In addition, complex data structures, history, alerts and events can be easily exchanged between servers.

OPC UA software promotes interoperability and scalability. It enables seamless integration between different systems and devices, regardless of the underlying hardware or software platforms. This flexibility allows industrial organisations to leverage their existing infrastructure while incorporating new technologies and expanding their operational capabilities.

In addition, the software supports platform-independent data modelling, which enables the representation of complex data structures and hierarchies. The ability to provide a secure and robust communication framework is also important. It uses various security mechanisms, including encryption, authentication and authorisation. This ensures that sensitive data remains safe in industrial systems.

The relationship between OPC UA software and Digital Twin technology comes into play when the Digital Twin needs to communicate and exchange data with other systems and devices in an industrial environment. OPC UA provides a standardised and secure way to connect the digital twin to physical assets, control systems and other software applications.

Using OPC UA, the digital twin can seamlessly exchange data with physical devices, control systems and other software components in real time. The digital twin can retrieve process data, history data and other relevant information using OPC UA communication. This allows the digital twin to accurately represent and simulate the behaviour of the physical resources or processes it mirrors.

OPC UA software can enable two-way communication. The digital twin can not only receive data but also send control commands or parameter adjustments to the physical asset via established communication channels. This feature allows the digital twin to act as a virtual controller or optimiser that can influence the behaviour and performance of the physical system.

What are AR and VR , and how do they relate to the 3D digital twin?

Augmented reality (AR) and virtual reality (VR) are technologies that add immersive virtual elements and experiences to the real environment. They enhance or completely replace the user’s perception of the real world.

According to ReportLinker, the global virtual reality market is expected to grow from $4.01 billion in 2022 to $4.54 billion by 2023 at a compound annual growth rate (CAGR) of up to 13.4%.

Fortune Business Insights, for its part, cites the global virtual reality market size as $44 billion by 2022. This is projected to grow from $25.11 billion in 2023 to $165.91 billion by 2030, a compound annual growth rate of 31% over the forecast period.

Although AR and VR have their own characteristics and uses, they can also be linked to the digital twin. In this article, we have highlighted a few examples of how these technologies can be applied together.

What is augmented reality (AR)?

Augmented reality(AR) refers to a technology that combines digital information, such as virtual objects, graphics or data, with a real environment. AR improves perception of the surrounding reality by adding computer-generated elements to the environment in real time, allowing users to interact with both virtual and physical elements simultaneously.

Augmented reality experiences can be delivered on a variety of devices, including smartphones, tablets, smart glasses and headsets. These devices use cameras, sensors and algorithms to detect and monitor the surrounding reality, allowing virtual content to be placed in the appropriate context.

Augmented reality has been widely applied in different industries. It is used in areas such as education, gaming, entertainment, retail, architecture, transport and healthcare. For example, in education, AR can provide interactive and engaging learning experiences by adding educational content to physical objects or environments. In retail, AR can allow customers to try on clothes virtually or visualise furniture in their homes.

What is virtual reality (VR)?

Virtual reality (VR) is a technology that creates an immersive, computer-generated environment that simulates the real or imaginary world.

VR aims to give users a fully virtual experience by stimulating their sight, hearing and sometimes even touch or movement. That’s why users typically wear VR headsets that cover their eyes and ears, blocking their perception of the physical world and replacing it with a virtual environment. Headsets often have built-in displays, motion sensors and sound systems that provide a convincing sense of presence and immersion in the virtual world.

VR is widely used in gaming and entertainment, where users can explore virtual worlds, interact with objects and participate in virtual activities. Virtual reality has also been applied in education, simulation, architectural design, mental health care and even rehabilitation.

It is worth noting that in some cases there is also an overlap between AR and VR, better known as mixed reality (MR). Augmented reality combines elements of both AR and VR to create experiences where virtual objects can interact with the real world and users can interact with both real and virtual elements simultaneously.

What benefits do AR and VR bring to the digital twin?

AR and VR offer added value and benefits to the digital twin, enabling organisations to make more informed decisions, optimise operations and improve overall production efficiency. Of these benefits, five main categories can be distinguished:

- Enhanced visualisation: AR and VR enable immersive and realistic visualisation of digital twins, allowing users to interact with virtual copies of physical resources, processes or systems. This visual presentation will increase understanding, facilitate collaboration and support decision-making.

- Real-time data layers: AR technology enables the integration of real-time data into a virtual model, providing machine operators and engineers with up-to-date information in their field of vision. Integrating data into the digital twin will improve situational awareness, help with monitoring and analysis, and support timely decision-making.

- Interactive simulation and training: VR technology creates a simulated environment where users can interact with their digital twin. This enables realistic training scenarios that allow users and maintenance staff to practice procedures, solve problems and improve their skills without the need for physical training equipment. It improves training efficiency, reduces costs and minimises risks.

- Remote collaboration and assistance: AR and VR facilitate remote collaboration by allowing multiple users to view and interact with the digital twin simultaneously. Experts can provide remote support and guidance to on-site staff via AR data planes or VR environments. This feature improves efficiency, reduces travel costs and allows information to be shared between teams in different locations.

- Predictive maintenance and optimisation: by integrating AR with VR’s digital twin, organisations can monitor real-time data and visualise performance metrics. This supports proactive maintenance by identifying potential problems, optimising maintenance schedules and minimising downtime. In this way, it is also possible to optimise processes and systems based on predictions from the virtual environment.

What is 3D modelling?

3D modelling is the process of creating a three-dimensional digital representation or model of an object or environment. The model is built using specialised software tools that accurately capture the shape, structure and appearance of the object.

The purpose of 3D modelling is to create a digital representation that mimics a real-world object or environment. This can include different elements such as geometry, textures, materials, colours and sometimes animation. 3D models are typically created using computer-aided design (CAD) or 3D modelling software.

The 3D modelling process typically starts with the creation of a wireframe or skeletal structure that defines the basic shape and structure of the object. This is followed by refining details, refining surfaces and adding textures and materials to improve the realism of the model. Depending on the complexity and purpose of the model, additional features such as lighting, animation or simulation can be included.

3D modelling is used in many different industries. In architecture and product design, 3D models are used to visualise and refine concepts, create prototypes and communicate ideas to customers or manufacturers. In the entertainment industry, 3D modelling is crucial for creating characters, props and environments for films, video games and virtual reality experiences. It is also used in scientific visualisation, medical imaging, industrial design, engineering and many other fields.

What is 3D simulation?

3D simulation is the process of creating and running computer models or simulations that reproduce real-world or imagined scenarios in a three-dimensional virtual environment. It involves the use of computer algorithms, mathematical models and simulation techniques to reproduce the behaviour, interactions and dynamics of objects, systems or phenomena.

The aim of 3D simulation is to study, analyse and predict the outcomes of complex systems or scenarios without physical experimentation. By simulating a virtual environment, users can interact with it. This allows different parameters, variables or scenarios to be tested, explored and evaluated.

In 3D simulation, the virtual environment is typically represented by a three-dimensional model containing the relevant features. These include the geometry, physics and behaviour of the objects or entities to be simulated. The model can include motion, forces, collisions, lighting and other physical features to create a realistic and dynamic simulation.

3D simulation is used in many different industries. In engineering, for example, 3D simulation is used to simulate the behaviour of structures, fluids or mechanical systems. This helps with design optimisation, performance analysis and testing. In computer graphics, 3D simulation is used to create realistic visual effects, animations and virtual worlds for movies, video games and virtual reality experiences.

3D simulation is also used in fields such as physics, chemistry, social sciences, healthcare and urban planning to model and understand complex phenomena and systems. It allows scientists, researchers and policy makers to simulate and explore scenarios that may be too costly, dangerous or time-consuming to explore in the physical world.

By running simulations, users can analyse the behaviour, interactions and outcomes of the simulated environment under different conditions. This allows them to make informed decisions, optimise processes and gain insights that can lead to improvements or innovations.

What is a 3D digital twin?

A 3D digital twin is a virtual representation or model of a physical object, system or environment that contains real-time data and simulations. It goes beyond the static 3D model by integrating dynamic and interactive elements that allow the digital replica to reflect the behaviour, characteristics and performance of its real counterpart.

A 3D digital twin is created by combining three key components: a physical object or system, real-time data collection and a virtual representation. A physical object can be anything; a building, a machine, a vehicle or even a whole city. Real-time data is collected from sensors, Internet of Things (IoT) devices or other sources related to a physical object or system. This information includes data on various parameters, conditions and performance indicators.

Real-time data is used to update and synchronise the digital twin. This ensures that it accurately reflects the current state of the physical object or system. Synchronisation allows continuous monitoring, analysis and simulation of the digital twin. Users can gain insights, predict behaviour and make informed decisions based on real-time information.

The 3D digital twin allows users to visualise and interact with a physical object or system. They can explore different perspectives, navigate the digital twin and get detailed information about its components, features and performance. Simulations and possible scenarios allow users to assess the impact of changes or measures, optimise operations and plan future improvements.

The 3D digital twins have a wide range of capabilities. In industry, energy and transport, digital twins are used to monitor and optimise operations, predict maintenance needs and simulate various efficiency and safety scenarios. In cities, digital twins can provide information on urban planning, traffic management and energy consumption. In healthcare, digital twins can help with personalised medicine, patient monitoring and surgical planning.

The integration of real-time data and simulations into a 3D digital twin provides a powerful tool for analysis, decision making and optimisation. It allows users to get a holistic view of a physical object or system, facilitating better understanding, prediction and management of behaviour and performance.