Challenge

There is a lot of information on machines and in many different systems. Access to the data poses challenges, as it is not compiled in an easily readable format and often involves long downtimes for machinery, for example. There is no information on total capacity use and it is impossible to predict maintenance. Sudden breakdowns of machinery cause significant costs and reduce production efficiency.

Solution

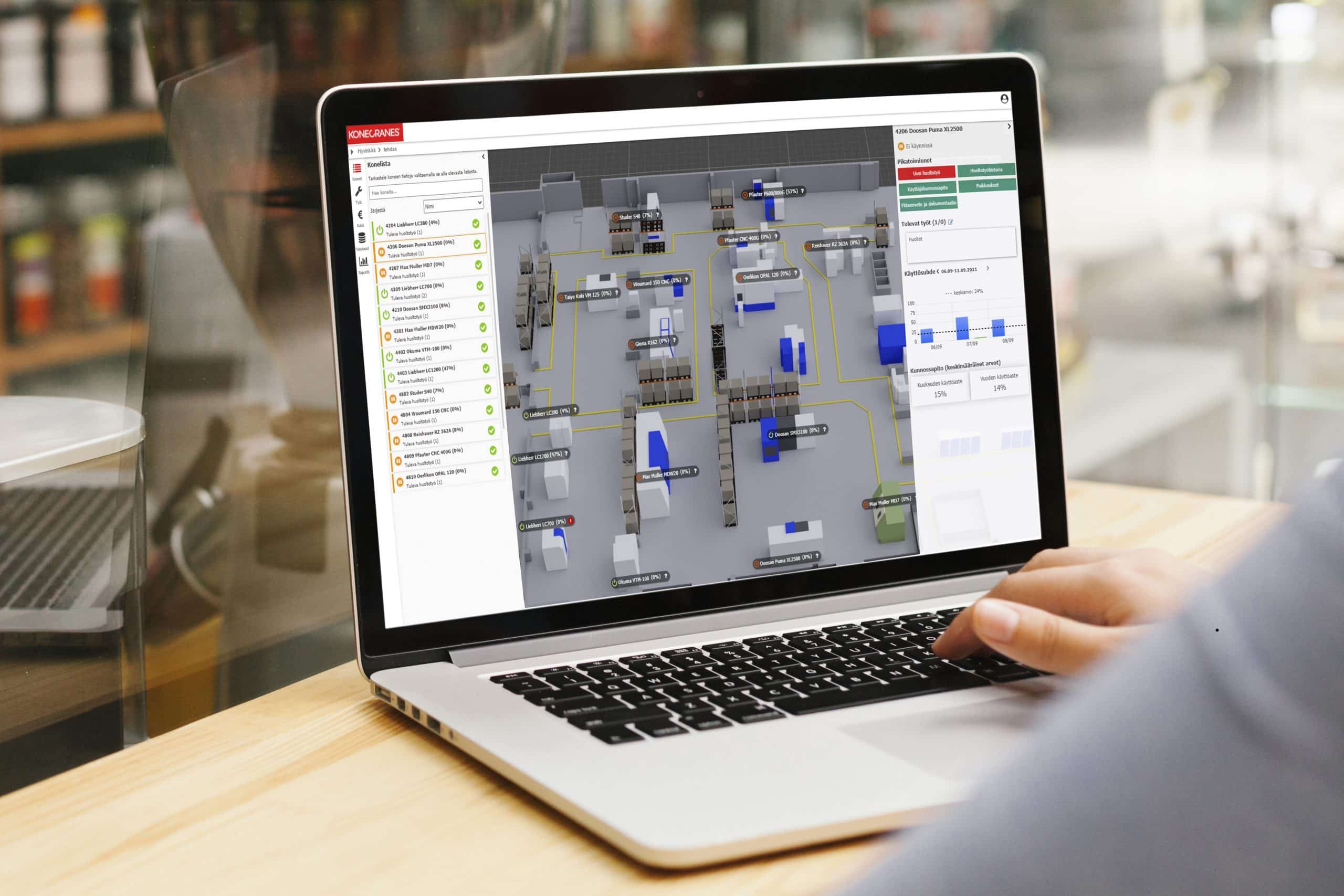

The Genius Core™ platform connects to all factory operations and production. The utilisation rate can be seen as part of the plant as a whole, but also visually per machine at a glance, which helps optimisation. Machine maintenance can be planned in advance when the overall condition of the machine, its wear and tear and modifications can be easily seen and monitored.

Key outcomes

Knowing the overall picture of the factory, the utilisation of machinery and optimal use of machinery will generate significant savings and improve production efficiency. Almost 700 hours of productive working time have been added to the week. The resulting data is no longer just a set of numbers, but part of a whole, such as plant flow, production planning, maintenance and safety measures. The Genius Core™ platform makes it easier to optimise operation and minimise energy costs.

All the information you need at one glance. One platform.

Want to know more about our solution for your organization? Please drop us a line and we’ll be in touch!