Challenge

It is difficult to control wasted hours without an overall picture of the factory or the operation of the machines. Small things like; waiting, alarms and set-up times disrupt production and add up to a significant number of wasted hours.

Solution

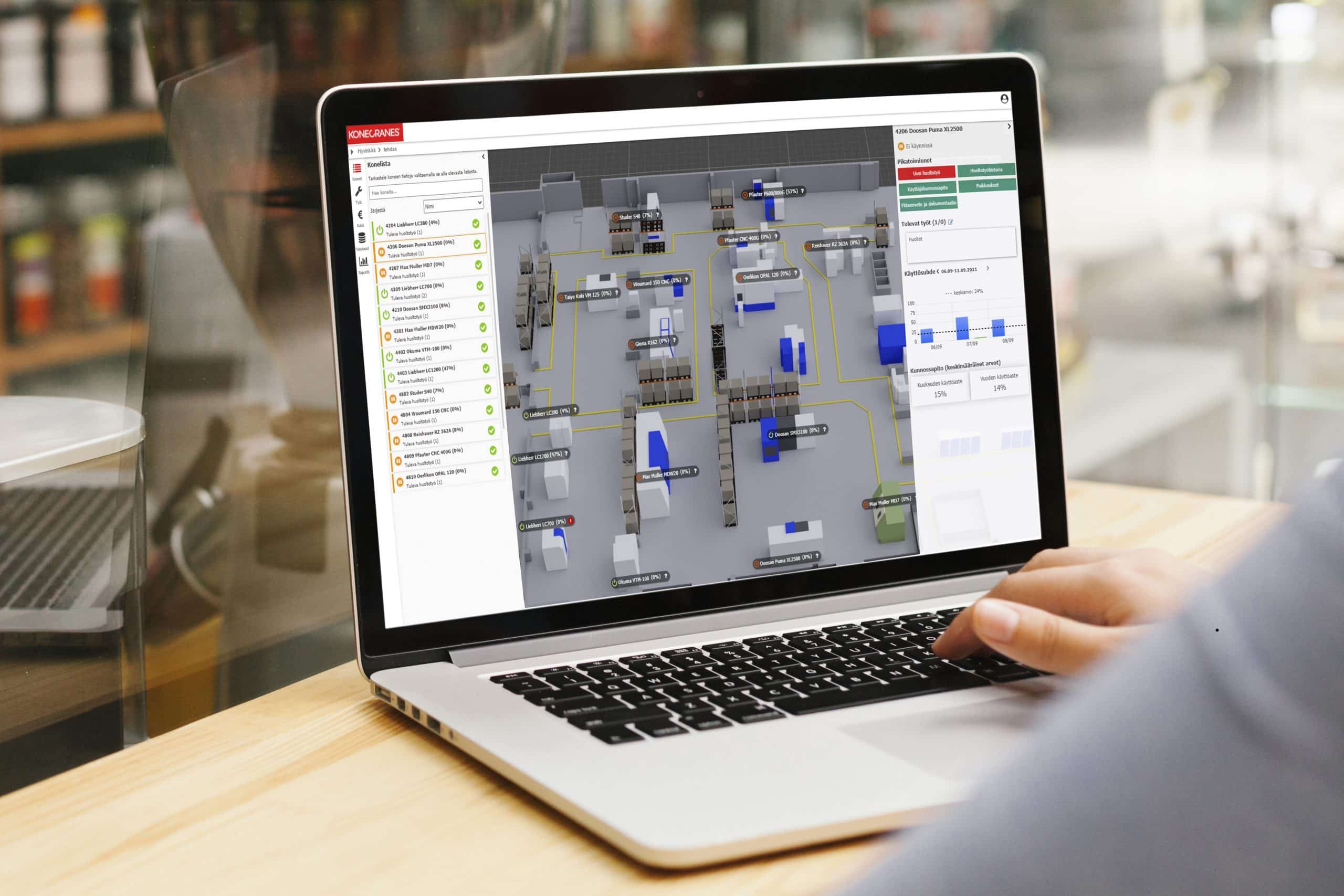

The Genius Core™ platform gives you access to production processes and wasted hours. From the platform, you can visually see a 24/7 real-time overview of the factory and individual production processes. Maintenance, alarms and set-up times that used to cause lost hours are now predictable.

Key outcomes

The Genius Core™ platform has reduced wasted hours by 30%. Seeing processes visually from start to finish allows them to be improved and, for example, anticipating maintenance has significantly reduced downtime. Production lines no longer stop because there is a backlog somewhere, everything is predictable.

All the information you need at one glance. One platform.

Want to know more about our solution for your organization? Please drop us a line and we’ll be in touch!