Challenge

Training in the use and maintenance of machinery is often problematic. The maintenance personnel are not permanent staff at the factory and may not have ever visited the factory before. The location of the machine, the parts needed for the repair and the use of the machine are the basics that should be known in advance. However, it is difficult to provide information without going to the machine. Often, the carer still has to go out to get more spare parts, due to a lack of information.

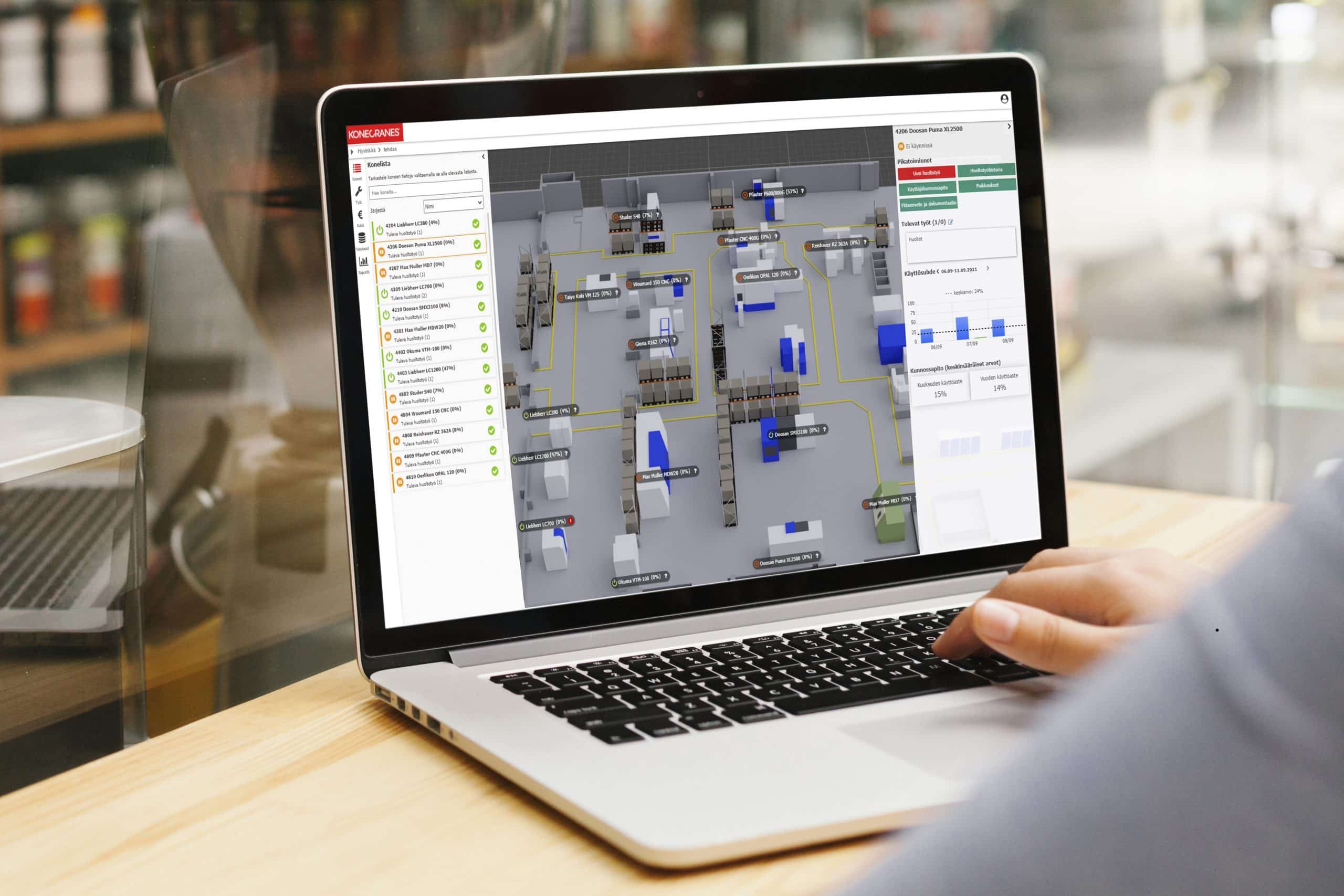

Solution

With the Genius Core™ platform, predictive maintenance and essential data is available at a glance. The platform shows where the machines are located in the factory and what parts the machine contains. It is possible for service staff to get to know their site in advance.

Key outcomes

Familiarisation and preventive maintenance is hassle-free and easy. You can see the information you need and the additional information you want to know about the machines, such as the parts that always need to be replaced during maintenance. The time savings are significant when a complete picture of all the equipment and its features is available without having to go on site and examine it.

All the information you need at one glance. One platform.

Want to know more about our solution for your organization? Please drop us a line and we’ll be in touch!