Challenge

In one of our client companies, large import machines malfunctioned or even shut down incorrectly for several days. The company did not have a single automated system and real-time data to monitor the status of production equipment and optimise schedules.

Solution

Using the Genius Core™ platform, the customer found that several machines were on standby for more than five hours without continuous active production systematically after night shifts. In standby mode one machine consumed 9000W and in active mode 9700W. This meant that each machine had consumed 9000W * 5h = 45kWh in standby mode. The inefficient operation of one of these machines resulted in losses of around €1000 per month.

Key outcomes

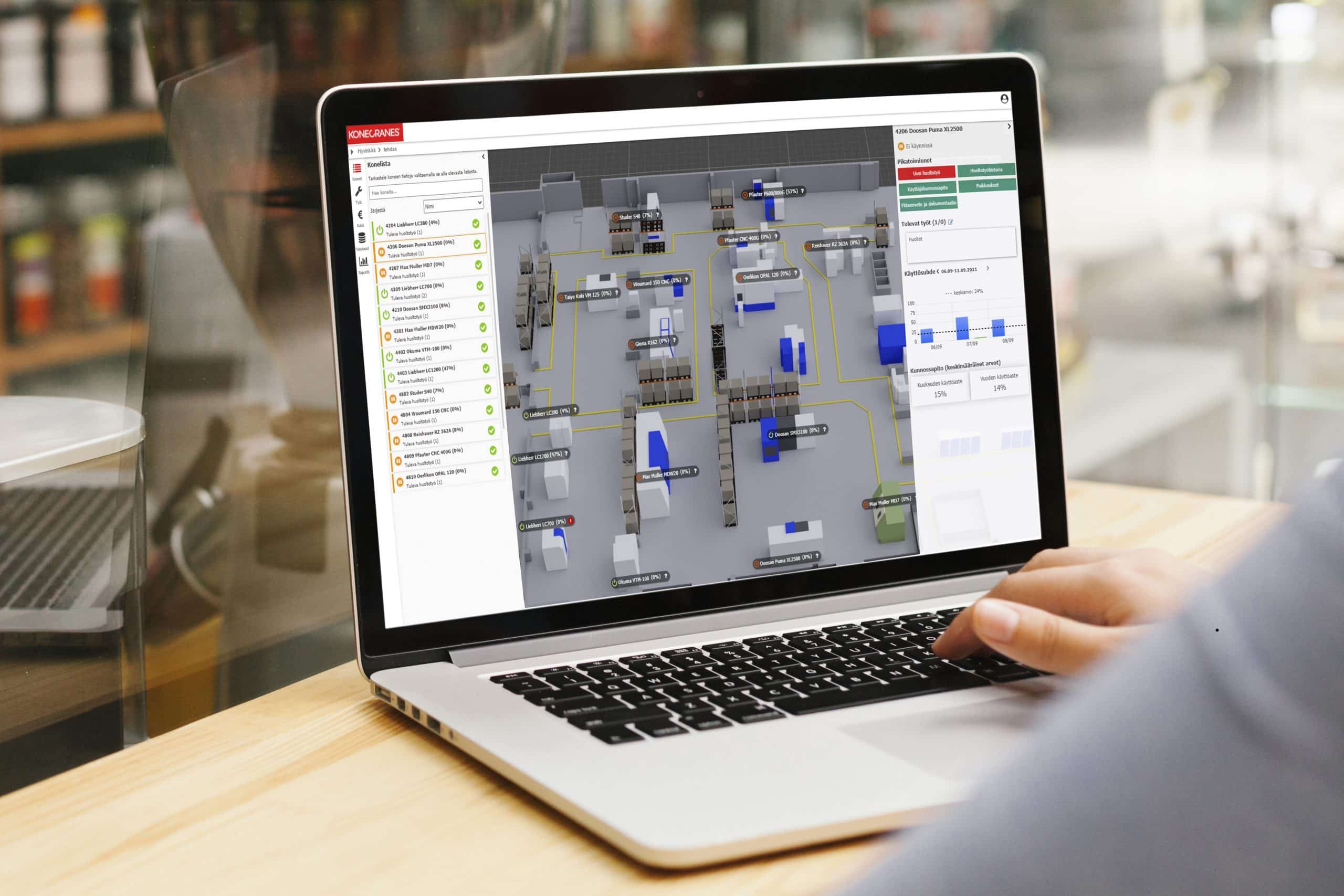

The customer now saves thousands of euros a month. The Genius Core™ platform helped the client to identify the sources and causes of excessive costs. As a result, customers increased efficiency because they spend less time processing and analysing data. Operators have access to real-time tools to help them make optimised production planning and faster, more informed decisions.

All the information you need at one glance. One platform.

Want to know more about our solution for your organization? Please drop us a line and we’ll be in touch!