Process Genius’ Genius Core™ also monitors processes at Snellman’s new factory

Family-owned company Snellman opened a new food factory in its hometown Pietarsaari, Finland. Opening the new factory also extended the collaboration with Process Genius.

The manufacturing process used at Snellman’s Kerava factory had already been visualized earlier using the 3D Digital Twin application. The new name of the app is Genius Core™. The application creates an identical, virtual copy of the physical factory (“a factory in your pocket”) by collecting and visualizing data from existing equipment and systems.

“Genius Core™ can be implemented without any upgrades to the production monitoring system or the acquisition of new systems. Regardless of that, Snellman switched from using bar codes to RFID technology in connection with the production visualization,” says systems specialist Guy Enkvist from Snellman.

Waste can be minimized by controlling the ripening process

One part of the new food factory in Pietarsaari is used for making Snellman’s meatballs, and the other part is used for making ready-made meals under the Kokkikartano brand. Monitoring the cooking process has proved to be a useful feature, since products remaining too long on the line leads to losses.

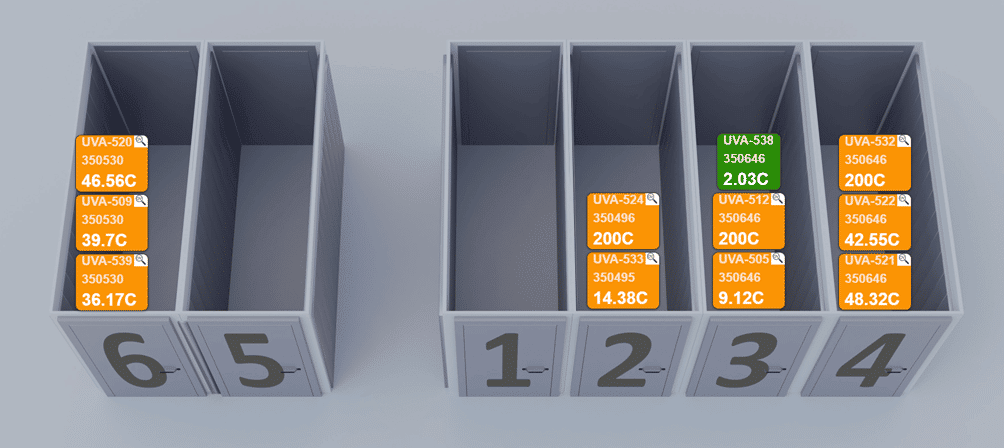

The cooling process is being monitored, and wireless temperature detectors provide information in real time. In practice, the factory’s self-monitoring system is connected to reference temperature monitoring. One screen provides both a real-time snapshot and information on the current temperature. The products have to cool to a certain temperature within a certain period of time, which is part of quality assurance. Colors are used to indicate the current status. “Green means that the target temperature of 6 degrees has been reached, whereas yellow means that it has not been reached quite yet,” Enkvist sums up.

The greatest added value from Genius Core™ comes from getting a comprehensive overview of the process.

The information obtained by monitoring is recoded physically using an RFID feed system, which utilizes radio waves. Sometimes the system does not function as expected and part of the data remains unrecorded. However, in such cases, the image can be used to make sure that the trolley gets in the oven and that the temperature control point is saved for self-monitoring.

“At the moment, almost 50 of the factory’s storage facilities have been visualized. Now the visualization also includes a filter function, with which users can use the storage location, item number or item name to search for specific stock products/stock levels. We will extend the collaboration even further,” says Customer Succes Manager Minna Partanen from Process Genius.

Factory in your pocket – get a real-time snapshot. Lead better, sleep better and ensure better production efficiency. Six (6) verifiable improvements a month – or you’ll get your money back!