Challenge

The machinery in the sector is state-of-the-art and the cost of producing high-quality products is high. During the production phase of the machines, work is slow, as flawless work is particularly important. However, design mistakes can happen to everyone, but they are often not noticed until the product is ready.

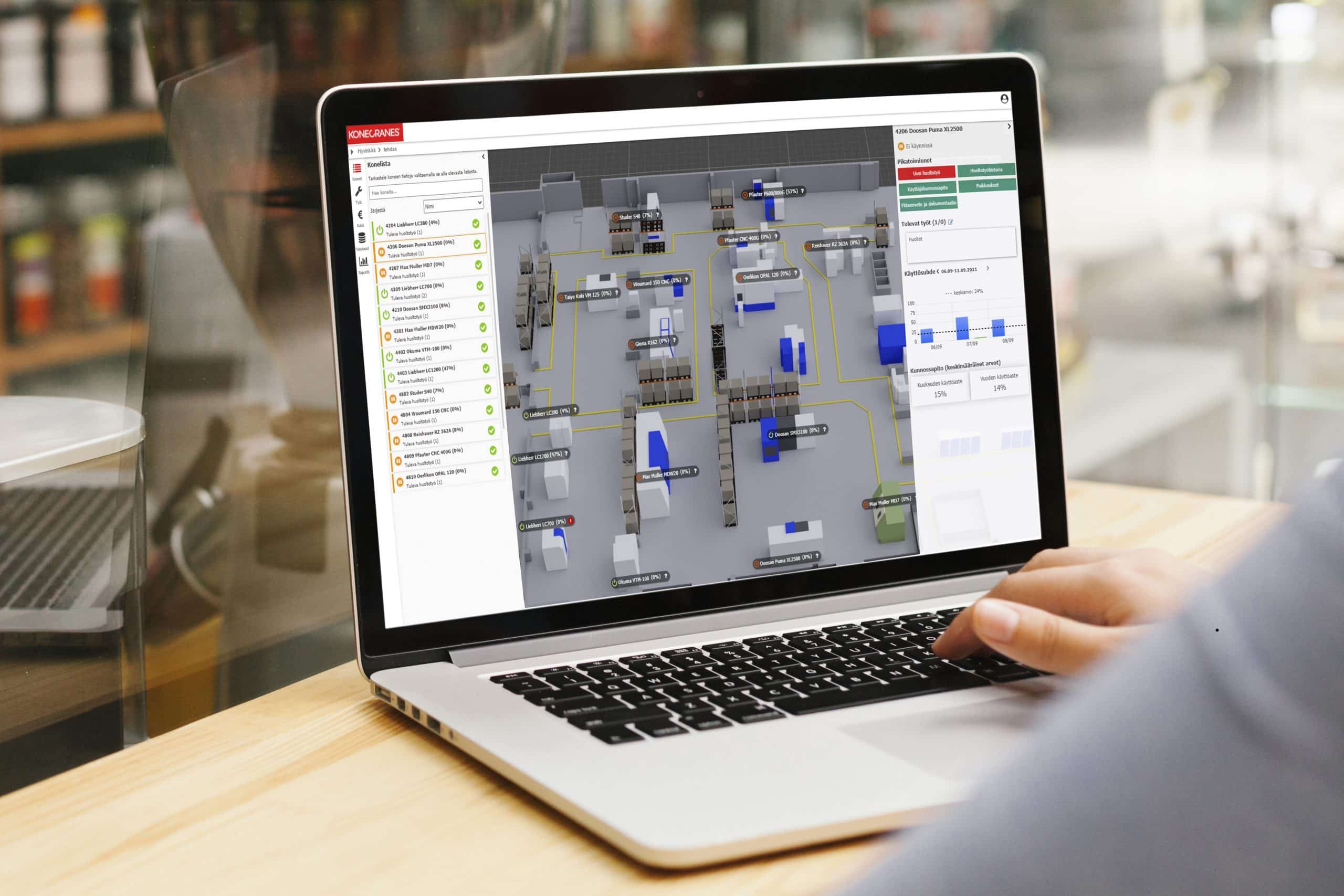

Solution

With the Genius Core™ platform, machines going into production can be modelled in advance. The modelling can be used to examine the trajectories and functionality of the machine and prevent design errors.

Key outcomes

Modelling has made work faster and the ability to model machines for potential customers anywhere, anytime really improves sales. The number of production errors has been reduced and the compatibility of parts as designed is guaranteed.

All the information you need at one glance. One platform.

Want to know more about our solution for your organization? Please drop us a line and we’ll be in touch!