Real-time Anomaly Detection in Manufacturing: a guide to quality, efficiency & predictive maintenance

Discover how real-time anomaly detection in manufacturing improves quality, prevents downtime, and drives efficiency with 3D Digital Twin

- What is anomaly detection in manufacturing?

- Why it matters: the business impact

- Types of anomalies in manufacturing data

- Data sources for anomaly detection

- Challenges in anomaly detection

- How a 3D Digital Twin helps

- Real-time anomaly detection with 3D Digital Twins

- SPC vs. Anomaly detection

- Anomaly detection use cases

- Quality assurance

- Process optimization

- Predictive maintenance

- Implementation strategy

- Future trends in anomaly detection

In manufacturing, the most expensive problems are the ones you don’t see coming. A bearing runs hot, a cutter drifts out of spec, a camera misses a subtle defect—minutes later you’re fighting scrap, rework, and downtime. That’s why leaders are moving from reactive alerts to real‑time anomaly detection: continuously analyzing sensor, machine, and process data to spot deviations from normal behavior before they snowball into failures.

Put simply, anomaly detection in manufacturing uses statistical and machine‑learning models to learn “normal” patterns in your operations—then flags unusual readings, sequences, or images the moment they appear. Paired with a 3D Digital Twin that visualizes live data on an interactive model of your line or facility, teams don’t just know that something is wrong—they see where and what, in context, so they can respond faster and with confidence.

The payoff is tangible: higher quality through early defect prevention, greater efficiency from fewer stoppages and quicker root‑cause analysis, cost savings via reduced scrap and unplanned downtime, and a stronger predictive maintenance program that fixes issues before they fail.

In this guide, we’ll give a practical, technical deep dive—types of anomalies, data sources, modeling approaches (from SPC to deep learning), how to run detection in real time, and how a 3D Digital Twin simplifies decision‑making on the factory floor.

What is anomaly detection in manufacturing?

In the simplest terms, anomaly detection is about spotting the “odd ones out” in your production data—anything that behaves differently from the usual. It’s like a seasoned operator who knows a machine’s normal hum and instantly notices when it sounds “off,” but automated and scaled across every line, shift, and facility.

From a technical perspective, anomaly detection is a branch of data analysis and machine learning focused on identifying data points, sequences, or patterns that deviate significantly from a model’s learned definition of “normal.” These models can be statistical, rule-based, or powered by artificial intelligence, and they work by analyzing historical and live operational data to flag unusual events in real time.

This is fundamentally different from simple monitoring. Basic monitoring uses fixed thresholds—if a temperature goes above 80°C or a cycle time exceeds 12 seconds, it triggers an alert. While useful, these thresholds can miss subtle issues that don’t cross preset limits but still signal a problem, or they can flood teams with false alarms from harmless fluctuations. Anomaly detection, on the other hand, looks at patterns and relationships across multiple data points—detecting gradual drifts, unusual combinations of readings, or rare events that a single threshold would overlook.

In a manufacturing context, anomalies can take many forms:

- A surface defect too small to be caught by the human eye during visual inspection.

- Abnormal machine vibrations that precede bearing failure.

- Out-of-spec process conditions, such as pressure and temperature drifting together in an unusual way.

- A sensor reading sequence that doesn’t match historical patterns for a given product run.

When paired with a 3D Digital Twin, anomaly detection becomes even more powerful. The twin acts as a living, visual replica of your plant or equipment, mapping real-time data to the exact location and component in the virtual model. Instead of reading a vague alert in a dashboard, maintenance and quality teams can see precisely where the anomaly is occurring and understand its context immediately—reducing investigation time and improving decision accuracy.

Why it matters: the business impact

In manufacturing, small deviations can have outsized consequences. A minor process drift or unnoticed defect can quickly escalate into scrap, rework, warranty claims, and dissatisfied customers—all of which eat into profit margins and brand reputation. According to the American Society for Quality, the cost of poor quality (CoPQ) can reach 15–20% of total sales revenue in some industries, factoring in internal failures, external failures, and prevention costs.

Unplanned downtime is another major financial drain. A recent Siemens study found that the average cost of a single hour of unplanned downtime in manufacturing can exceed $250,000, with some high-value sectors like automotive reporting annual losses in the hundreds of millions. These stoppages don’t just hurt output—they disrupt supply chains, delay deliveries, and damage customer trust.

Safety is also on the line. Anomalies can be early indicators of hazardous situations: a press running hotter than usual, a conveyor vibrating beyond safe tolerances, or an unexpected spike in electrical load. By detecting these deviations before they escalate, manufacturers can reduce workplace accidents, protect operators, and ensure regulatory compliance. For practical strategies on improving health, safety, and environmental performance, see this detailed guide on HSE best practices.

In the era of Industry 4.0, where data-driven decision-making and connected systems define competitive advantage, anomaly detection isn’t just a “nice-to-have”—it’s a core capability. Companies that integrate anomaly detection into their operations can respond faster, optimize resources, and turn real-time insights into strategic wins.

Paired with a 3D Digital Twin, the business impact multiplies. Instead of sifting through complex dashboards, decision-makers see live, visual context of each anomaly—making it easier to prioritize interventions, allocate the right resources, and maintain smooth, efficient production at scale. In a competitive global market, that speed and clarity can be the difference between leading the pack and playing catch-up.

Types of anomalies in manufacturing data

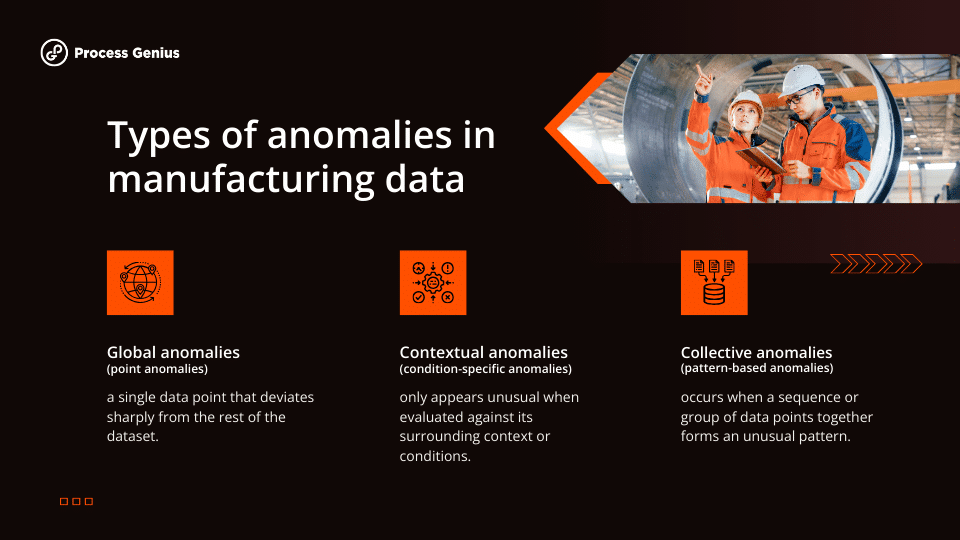

Not all anomalies are created equal. In manufacturing, unusual data patterns can take different forms, each requiring a specific approach to detection and interpretation. Understanding these categories helps you select the right detection method and respond appropriately when issues arise.

1. Global anomalies (point anomalies)

A global anomaly is a single data point that deviates sharply from the rest of the dataset. It’s the easiest type to detect because the outlier is clearly outside the expected range of values.

Example:

- A temperature sensor on a furnace suddenly spikes to 350°C when the typical range is 150–200°C.

- A production cycle time jumps to 90 seconds when the norm is 50–55 seconds.

Why it matters: Global anomalies often indicate acute issues—equipment malfunctions, operator errors, or data entry mistakes—that require immediate attention.

2. Contextual anomalies (condition-specific anomalies)

A contextual anomaly only appears unusual when evaluated against its surrounding context or conditions. In other settings, the same value might be perfectly normal.

Example:

- A press operates at a higher temperature during a heavy load shift, which is normal. But the same temperature during a low-load shift is abnormal.

- A conveyor’s vibration reading spikes during product changeovers, which is expected—unless it happens mid-run without any operational change.

Why it matters: Contextual anomalies are critical for nuanced detection. They often point to process-specific issues, such as misaligned settings, incorrect material handling, or load mismatches.

3. Collective anomalies (pattern-based anomalies)

A collective anomaly occurs when a sequence or group of data points together forms an unusual pattern, even if the individual points don’t seem suspicious on their own.

Example:

- A gradual upward drift in motor current over several hours, signaling wear or impending failure.

- A series of slightly longer-than-average cycle times spread over multiple shifts, hinting at a hidden bottleneck.

Why it matters: These anomalies are often the hardest to spot without advanced time-series analysis or machine learning models. They can indicate slow-developing issues like tool wear, component degradation, or subtle process inefficiencies. This is where industrial data analytics plays a crucial role—transforming raw machine and sensor outputs into actionable insights. For more on why analytics is the backbone of modern, data-driven manufacturing, see this guide to the importance of industrial data analytics.

3D Digital Twin advantage

When these anomalies are mapped into a 3D Digital Twin of the plant, they become far easier to interpret. Instead of scanning a spreadsheet or dashboard, teams can instantly see the exact machine, line, or location affected, along with related sensor data—making root cause analysis faster and reducing response time.

Data sources for anomaly detection

Anomaly detection is only as effective as the data it analyzes. In manufacturing, that data comes from a diverse range of sources—each offering a unique lens into operations. When combined, these inputs provide a comprehensive view of machine health, process performance, and product quality.

IoT sensors

Connected sensors continuously measure parameters such as temperature, vibration, pressure, humidity, torque, and power consumption. These real-time readings are often the first indicators of abnormal behavior—whether it’s a motor running hotter than usual, a sudden pressure drop in a hydraulic line, or unexpected vibration in a conveyor drive.

Vision systems

High-resolution cameras and computer vision algorithms inspect products for defects in real time. They can detect surface scratches, misalignments, color inconsistencies, or missing components far faster and more consistently than human inspection. When integrated into an anomaly detection pipeline, vision systems can trigger immediate alerts to stop defective parts from advancing down the line.

MES & ERP data

Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems track production schedules, batch histories, resource allocation, and order fulfillment. Changes in production rates, unusual resource usage, or deviations from planned workflows can be subtle signs of inefficiency or systemic problems. MES and ERP data add valuable context to sensor readings, helping distinguish between a true anomaly and an expected process change.

Machine logs & SCADA systems

Supervisory Control and Data Acquisition (SCADA) systems and machine logs record operational states, alarms, operator inputs, and event histories. Analyzing these logs alongside real-time data can reveal patterns—such as recurring faults at a certain time of day or after specific operational changes—that might not be obvious in sensor data alone.

The data noise challenge

The more data sources you have, the richer your anomaly detection capabilities—but also the more “noise” you must filter out. Different systems may store data in different formats, update at different intervals, or even record conflicting values. Without proper integration and filtering, you risk drowning in false positives or missing critical issues entirely.

A 3D Digital Twin helps overcome this challenge by acting as a single visual hub for all data streams. Instead of navigating multiple dashboards and raw log files, operators see anomalies plotted in real time on an interactive 3D model of the plant—cutting through noise and focusing attention on the most relevant, actionable insights. This is made even easier with seamless integrations between the Digital Twin and your existing systems, ensuring all critical data is connected, consistent, and accessible in one place.

Challenges in anomaly detection

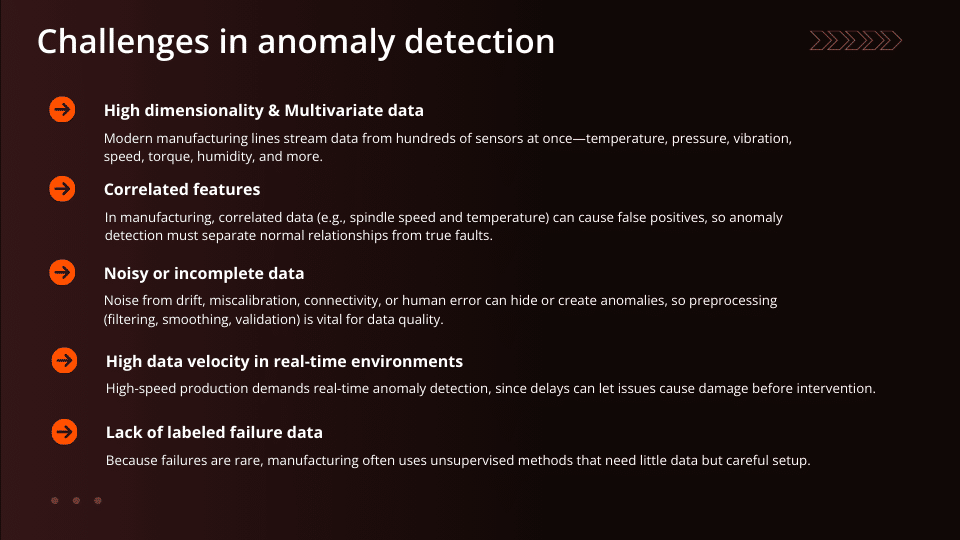

1. High dimensionality & Multivariate data

Modern manufacturing lines generate data from hundreds of sensors and systems simultaneously—temperature, pressure, vibration, speed, torque, humidity, and more. Each parameter can influence others, creating a multivariate environment that’s far more complex than monitoring a single variable. Analyzing this high-dimensional data requires advanced algorithms capable of capturing the relationships between variables without oversimplifying them.

2. Correlated features

In manufacturing, many data points are naturally correlated. For example, spindle speed and cutting temperature often rise together. A naïve anomaly detection approach might misinterpret this correlation as an anomaly, triggering false positives. Sophisticated detection methods need to distinguish between normal correlations and genuinely abnormal behavior.

3. Noisy or incomplete data

Sensor drift, miscalibration, intermittent connectivity, or human input errors can introduce “noise” into datasets. This noise can mask anomalies or create false ones. Preprocessing steps like filtering, smoothing, and validation are essential to ensure only high-quality data feeds into the detection system.

4. Lack of labeled failure data

Supervised machine learning methods depend on historical examples of both normal and anomalous behavior. In many manufacturing environments, detailed failure data is scarce because breakdowns are infrequent or underreported. This limitation often pushes teams toward unsupervised or semi-supervised methods, which can work without extensive labeling but require careful tuning.

5. High data velocity in real-time environments

High-speed production lines produce vast amounts of data every second. Anomaly detection systems must process this data in real time to prevent delays in decision-making. If detection takes too long, anomalies might cause damage before anyone can intervene

How a 3D Digital Twin helps

A 3D Digital Twin addresses many of these challenges by serving as a unified, real-time visualization layer. Instead of operators combing through complex datasets, the twin aggregates data streams, contextualizes anomalies with location and equipment details, and filters out irrelevant noise.

One powerful approach is to use Points of Interest (POIs)—specific, predefined locations or components within the 3D model where relevant anomaly-related data is grouped and structured. This method makes it easier to track, compare, and analyze recurring issues in context, without being overwhelmed by unrelated information. POIs allow maintenance teams to instantly zoom in on affected areas, review historical anomaly patterns, and prioritize interventions. You can learn more about how POIs work in this detailed explanation.

By combining anomaly detection with POI-based visualization, manufacturers not only detect problems faster but also create a structured knowledge base of issues—making root cause analysis and prevention strategies much more effective.

Real-time anomaly detection with 3D Digital Twins

In high-speed manufacturing, the value of anomaly detection isn’t just in spotting problems—it’s in spotting them fast enough to act before they cause downtime, scrap, or safety incidents. This is where combining real-time anomaly detection with a 3D Digital Twin becomes a game changer.

A 3D Digital Twin integrates live sensor feeds, MES/ERP data, vision system outputs, and machine logs into a single, interactive 3D model of your plant or production line. As anomalies are detected—whether by statistical methods, machine learning models, or a combination—the data is instantly linked to the corresponding location or asset in the twin.

Example in action:

A vibration anomaly is detected on a packaging machine’s drive motor. Instead of sending a generic “Motor Vibration High” alert, the system immediately highlights the exact motor within the 3D twin, flashing a visual indicator and displaying related sensor data in context. The maintenance team receives both the alert and a clickable view of the live 3D model. With a single glance, they can see where the problem is, what is affected, and how it’s behaving right now.

This approach brings two major benefits:

- Faster decision-making – Operators and engineers don’t need to cross-reference multiple dashboards, spreadsheets, or paper reports. All relevant data is aggregated, visualized, and contextualized in one place—reducing the time from detection to action.

- Reduced alert fatigue – Traditional monitoring can overwhelm teams with hundreds of low-priority alerts. A 3D Digital Twin makes it easy to filter noise by visually prioritizing anomalies that are most urgent or have the biggest operational impact, helping teams focus on what matters.

By turning streams of complex data into an intuitive, location-aware visual experience, real-time anomaly detection with 3D Digital Twins transforms how manufacturers respond to problems—shifting from reactive firefighting to proactive, confident intervention.

SPC vs. Anomaly detection

Statistical Process Control (SPC) has been a cornerstone of manufacturing quality for decades. It works by establishing fixed control limits—based on historical process data—and flagging any measurements that fall outside these predefined boundaries. SPC excels when dealing with well-understood, stable processes where the normal operating range is predictable. For example, in a mature production line with minimal variation, SPC can reliably spot deviations caused by tool wear, operator error, or material changes.

However, SPC has its limitations. Because it depends on static thresholds, it may miss subtle, emerging trends that don’t yet cross those boundaries. Likewise, processes with complex interactions or frequent changes (such as mixed-model production lines) can produce false alarms when natural variability is mistaken for a problem.

Anomaly detection, on the other hand, is adaptive and dynamic. Instead of relying solely on fixed limits, it uses statistical models, machine learning, and multivariate analysis to learn the normal behavior of a system in real time. It can detect gradual drifts, unusual combinations of measurements, and rare patterns that SPC would overlook. This makes it ideal for complex, variable, or high-speed processes—especially in Industry 4.0 environments where multiple data streams need to be analyzed simultaneously.

When to use each approach:

- SPC: Best for stable processes with consistent patterns and well-established quality standards.

- Anomaly Detection: Best for variable processes, rapidly changing production environments, or when early detection of subtle issues is critical.

When to combine them:

Many manufacturers find the best results by layering SPC and anomaly detection. SPC provides the foundation for maintaining compliance with established quality limits, while anomaly detection adds an extra layer of intelligence—spotting early warning signs before they become SPC violations.

When paired with a 3D Digital Twin, the combination becomes even more powerful. SPC flags known limit breaches, anomaly detection finds hidden patterns, and the twin visualizes both in real time—so teams not only know that something is wrong, but where and why. This unified approach enables faster intervention and more effective continuous improvement.

Anomaly detection use cases

Anomaly detection—especially when empowered with a 3D Digital Twin—can transform operations across multiple areas of manufacturing. Here are some of the most impactful applications, along with examples that show real-world value.

Quality assurance

Detecting defects, mislabeling, and structural inconsistencies before products leave the line.

Challenge

A beverage manufacturer uses high-resolution vision systems integrated into anomaly detection algorithms to identify subtle label misalignments. These are instantly visualized in the 3D Digital Twin at the exact packaging station, allowing operators to correct the issue.

ROI impact

Reduction in product recalls and returns, saving an estimated €150,000 annually by avoiding defective shipments.

Process optimization

Identifying bottlenecks, inefficiencies, and non-value-added steps.

Challenge

In an automotive parts plant, anomaly detection highlights a recurring delay between two assembly stations. The Digital Twin visualization shows the delay is linked to an operator waiting for components from upstream. Adjusting shift scheduling resolves the bottleneck.

ROI impact

Increased throughput by 8% with no additional labor cost

Predictive maintenance

Spotting early warning signs of equipment failure through vibration, temperature, or pressure anomalies.

Challenge

A CNC machining facility monitors spindle vibration and cutting temperature. The anomaly detection system identifies a gradual but unusual vibration pattern, flagging it in the 3D Digital Twin’s view of the machine. Maintenance is scheduled before the bearing fails.

ROI impact

Avoidance of 12 hours of unplanned downtime—valued at €75,000 in lost production—plus the cost of emergency repairs.

Implementation strategy

Step 1: Define objectives

Start by clarifying what you want to achieve. Are you focused on reducing downtime through predictive maintenance, cutting scrap by catching quality issues early, or improving safety by detecting hazardous conditions? A clear set of objectives ensures the project is tied to measurable ROI rather than being just a technology experiment.

Step 2: Identify data sources

List all potential inputs: IoT sensors, vision systems, MES/ERP data, SCADA logs, and more. Prioritize the sources most relevant to your defined objectives. For example, if your goal is predictive maintenance, vibration and temperature data are critical. If the goal is quality, camera inspection and MES records are more important.

Step 3: Integrate a 3D Digital Twin

Next, create a 3D Digital Twin of your production environment. This serves as the visual foundation where data streams will converge. The twin not only contextualizes anomalies but also makes them understandable across teams. Instead of a long list of sensor IDs, operators see the exact machine or component highlighted in real time.

For a practical roadmap on how to get started, see this ground-level guide to implementing a Digital Twin.

Step 4: Connect anomaly detection pipelines

Feed your chosen anomaly detection models—statistical, machine learning, or hybrid—into the twin. This ensures anomalies are not only detected but also placed in context. For example, a rising temperature in a motor is visualized in the 3D twin on that exact motor, complete with historical data for comparison.

Step 5: Deploy real-time dashboards & Alerting

Set up dashboards that combine numerical data with the visual twin.

Step 6: Continuous development & Twin updates

Manufacturing environments are dynamic—new machines, product changes, and process tweaks are constant.

Another important consideration is scalability. The more data points, machines, and processes you want to monitor, the more powerful and scalable your 3D Digital Twin needs to be. This ensures that as your factory grows, your anomaly detection system grows with it—without compromising performance. To support this, Process Genius offers a flexible pricing model for Genius Core 3D Digital Twin, allowing manufacturers to start small and expand as their needs evolve.

Future trends in anomaly detection

The future of anomaly detection in manufacturing is not just about spotting problems faster—it’s about making insights more accessible, intelligent, and immersive. Two trends stand out as especially transformative: AI integration and VR-enabled Digital Twins.

AI-powered 3D Digital Twin integrations

As factories become more connected, manufacturers are increasingly looking for ways to interact with their data more naturally. One emerging direction is AI assistants integrated into 3D Digital Twins. Imagine asking your twin, “Show me all anomalies from the past 24 hours on Line B”—and instantly seeing them highlighted in context. Or receiving AI-driven recommendations such as, “This vibration pattern indicates likely bearing wear; schedule maintenance in the next 48 hours.”

For this to work, the Digital Twin platform must be built to support AI integrations from the ground up. Genius Core already provides this flexibility, ensuring manufacturers can extend their twin with conversational AI, predictive algorithms, or custom analytics without rebuilding their data foundation.

AI-powered 3D Digital Twin integrationsVR for even better operational awareness

Another major leap is the use of virtual reality (VR) for real-time operational awareness. Instead of physically walking the factory floor, managers and engineers can step into a VR-enabled 3D Digital Twin to explore live production conditions, investigate anomalies, and collaborate with teams—no matter where they are in the world.

This isn’t a distant vision: Genius Core already offers capabilities that make VR awareness possible, enabling decision-makers to “be on site” virtually, seeing live data mapped onto equipment and processes in a fully interactive 3D environment.

Anomaly detection has become a cornerstone of modern manufacturing, enabling companies to move from reactive firefighting to proactive control. By identifying defects, inefficiencies, and risks early, manufacturers can safeguard quality, reduce downtime, and operate more efficiently.

When combined with a 3D Digital Twin, the value multiplies. Instead of dealing with fragmented dashboards and endless data streams, teams see anomalies in context—mapped to the exact machine, line, or process within an interactive 3D model. This clarity accelerates decision-making, reduces alert fatigue, and ensures that the right action is taken at the right time.

In the era of Industry 4.0, where competitive advantage depends on data-driven operations, adopting anomaly detection with Digital Twin technology is no longer optional—it’s a strategic imperative. Platforms like Genius Core make it possible to start small, integrate seamlessly with existing systems, and scale as your needs grow.

–> Ready to explore how a 3D Digital Twin can simplify anomaly detection and strengthen your Industry 4.0 journey? Take a look at our guides and resources or get in touch with our team for a consultation. Together, we’ll help you transform your data into actionable insights that drive measurable results.

Digital Marketing & Business Specialist