Understanding connected manufacturing

A practical guide to connected manufacturing using real-time data, integrated systems, and 3D Digital Twins to improve visibility, efficiency, and decision-making.

Manufacturers are under pressure to do more with less: less time, less energy, less waste, and fewer people on the shop floor. Connected manufacturing is about linking machines, people, systems, and data so they work as one, instead of as separate islands. When production lines, warehouses, quality, maintenance, and supply chain all share real-time information, decisions become faster, problems are spotted earlier, and improvement stops being a one-off project and becomes part of daily work.

At the same time, a modern factory is a mix of many different roles — operators, engineers, supervisors, planners, maintenance teams, and management — all with different information needs and different KPIs to follow. What is important for an operator may not be what matters for a planner, and what a maintenance technician needs to see is not what a quality engineer needs. This creates a challenge: more connected data does not automatically mean the right data for everyone.

This complexity also increases the importance of data security. As more systems, teams, and external partners become connected, safeguarding the right level of access becomes critical. User-role–based access is now a core requirement of any modern connected manufacturing environment. Everything should be connected — but connected wisely, carefully, and safely.

In a connected manufacturing environment, data flows from sensors and machines on the shop floor into systems like MES, ERP, CMMS, and quality tools, and then into the cloud for deeper analytics, AI, and digital twin models. Operators see what’s happening now, not what happened yesterday. Leaders can compare plants and lines side by side. Maintenance teams know which asset needs attention next. Supply chain teams see the impact of changes before they hit customers.

This guide explains what connected manufacturing is, how it works in practice, where the real value comes from, and how to build a realistic roadmap from your current state to a fully connected operation. It also covers common pitfalls, key metrics to track, and how technologies like IIoT, cloud platforms, and digital twins fit into a practical, step-by-step transformation.

What Is Connected Manufacturing?

Connected manufacturing is the practice of linking machines, systems, people, and data across an entire production environment so everything works together in real time. Instead of each department or machine operating as its own island, connected manufacturing creates a single flow of information—from the shop floor to the top floor—and across the full supply chain.

At the core, connected manufacturing combines three things:

- Data coming from machines, sensors, equipment, quality checks, operators, and software systems. If you want to learn more about how this works in practice, we’ve written a deeper article on the role of IoT, AI, and Digital Twins in predictive maintenance.

- Connectivity between systems like MES, ERP, CMMS, QMS, PLM, and warehouse or logistics platforms.

- Intelligence, using the cloud, edge computing, analytics, and digital twins to turn raw data into decisions.

In a connected manufacturing setup, machines report their status automatically, operators receive guidance through digital tools, and managers see production performance live—not through end-of-shift reports. Information moves instantly between production, maintenance, quality, planning, and supply chain, creating the foundation for industrial data analytics, which helps teams prevent issues instead of reacting to them.

Rather than relying on manual updates, spreadsheets, or delayed reports, a connected factory builds a shared “source of truth” for everything happening on the shop floor. This enables faster decision-making, consistent workflows, higher efficiency, and a safer, more predictable manufacturing environment.

Connected manufacturing isn’t a specific technology—it’s a way of operating that brings all technologies and teams together into one coordinated, data-driven ecosystem.

The Connected Manufacturing ecosystem

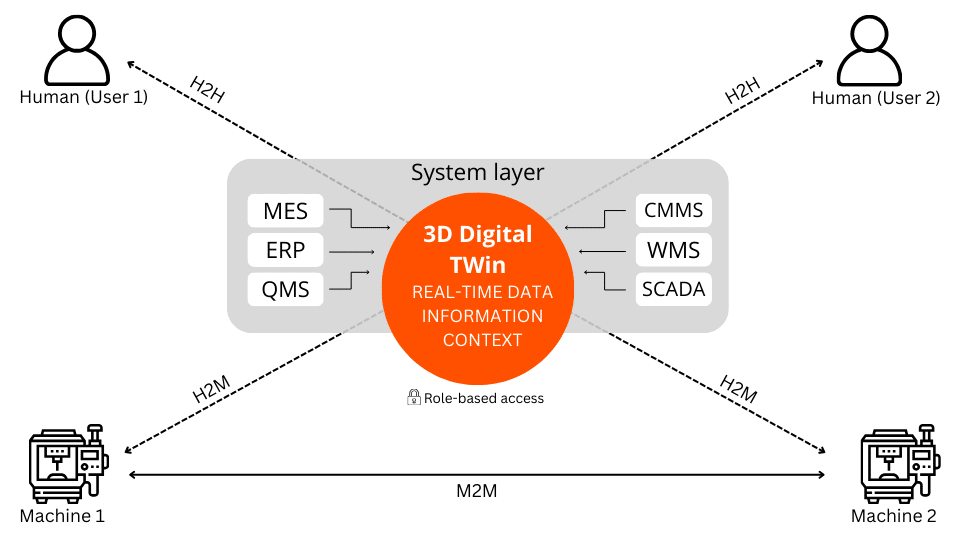

Building a truly connected manufacturing environment means bringing together the different ways machines, systems, and people communicate inside a factory. These interactions usually fall into three core categories: machine-to-machine (M2M), machine-to-human (M2H), and human-to-human (H2H). When all three communication layers work together—and when they are visualized and integrated through a Digital Twin—the result is a manufacturing operation that is faster, smarter, and easier to manage.

Below is a clear breakdown of each communication type and how they fit into a connected ecosystem.

Machine-to-Machine (M2M) Communication

M2M communication enables machines, devices, and automation systems to share information and respond to each other autonomously—without human involvement. It’s the foundation of modern smart manufacturing, allowing equipment to coordinate actions, adjust parameters, and respond to changing conditions in real time.

Examples include:

- Sensors transmitting temperature, vibration, and pressure data

- PLCs coordinating machine sequences on a production line

- Robots signaling downstream systems to speed up or slow down

- IIoT devices detecting anomalies and triggering early diagnostics

M2M communication is essential for predictive maintenance. Networks of IIoT sensors track performance data and send it to an analytics system that detects abnormal patterns. If a machine shows early signs of failure, alerts and work orders can be triggered instantly.

M2M relies on technologies such as:

- OEM-embedded sensors

- Industrial networks

- Edge computing devices

- SCADA and PLC infrastructure

This creates a real-time stream of machine data that becomes the backbone for automation and decision-making.

Machine-to-Human (M2H) Communication

M2H communication ensures that workers always know what is happening on the shop floor. Machines use established communication channels to deliver critical information to operators, technicians, and supervisors in real time.

Typical M2H communication includes:

- Human-machine interfaces (HMIs) showing machine status, warnings, or performance metrics

- Mobile devices providing alerts, digital instructions, and job updates

- AR/VR tools that help workers troubleshoot, assemble, or repair equipment

- Wearables that notify users about safety hazards or out-of-spec conditions

M2H also includes collaboration with cobots, where humans and robots work safely together to complete tasks. Cobots assist with repetitive or physically demanding work such as welding, packing, or assembly. In addition, the modern approach to industrial monitoring now also includes M2H interactions with quadruped robots (“robot dogs”), which can navigate the factory independently, collect data, and support operators in areas that are difficult or unsafe to access. All of this is designed to help teams stay productive while reducing fatigue and human error.

With strong M2H communication, workers can respond quickly to issues, follow standardized workflows, and maintain higher awareness of production conditions. In more advanced setups, this also includes real-time anomaly detection.

Human-to-Human (H2H) Communication

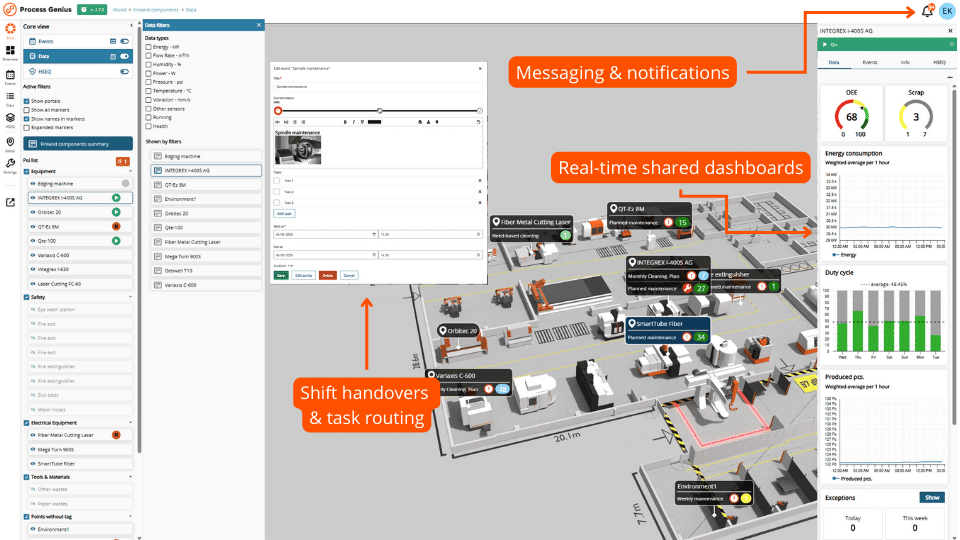

H2H communication supports coordination, teamwork, and decision-making across shifts, departments, and sites. Even in the most automated facilities, people still need to communicate clearly—and connected technologies help make that easier and more efficient. This level of communication is also essential for strong HSE performance, where timely information and clear escalation workflows directly impact safety and compliance.

Examples include:

- Digital shift handovers

- Instant messaging and task routing

- Real-time shared dashboards

- Video calls with experts outside the facility

- Connected worker apps with built-in escalation workflows

H2H communication reduces delays, eliminates guesswork, and ensures teams always work from the same information. For high-mix or rapidly changing production environments, this level of coordination is essential.

Connected worker solutions often combine H2H and M2H communication, giving teams the tools they need to act quickly with confidence, supported by real-time data from the shop floor.

The role of the 3D Digital Twin: the unifying layer

While M2M, M2H, and H2H provide the communication foundation, a modern factory still needs a central system to tie everything together. This is where your 3D Digital Twin (Genius Core) becomes essential.

The Digital Twin serves as the integration and visualization layer for the entire ecosystem. It brings all communication channels—machines, systems, and people—into one unified view.

The 3D Digital Twin acts as:

- A real-time operational mirror of the factory. It shows machines, equipment, assets, production lines, alerts, and workflows exactly as they are happening.

- A single location for all data. It integrates data from MES, ERP, CMMS, QMS, SCADA, IoT platforms, and sensors into one shared interface.

- A visibility and collaboration hub. Operators, engineers, maintenance teams, and managers see the same information at the same time.

- A scalable foundation. As new machines, systems, or sites are added, the Digital Twin expands without disrupting operations.

- A bridge across all communication layers. M2M data is visualized and easier to interpret. M2H alerts and workflows are shown in full context. H2H collaboration is strengthened with shared, real-time visibility.

With the Digital Twin acting as the central “command center,” the entire manufacturing ecosystem becomes more predictable, transparent, and connected.

Why Connected Manufacturing matters

Connected manufacturing matters because it turns a factory from a collection of separate machines and departments into a coordinated, responsive, and data-driven operation. When machines, systems, and people are connected, you gain real-time visibility, faster reaction times, and a more predictable way of running production. Instead of relying on delayed reports, manual checks, or isolated tools, teams see what is happening right now and can act before problems grow.

The benefits of connected manufacturing can be measured in everyday outcomes:

| Benefit | What it means | Impact / Results |

| 1. Faster issue detection and shorter downtime | When machines and systems share information instantly, problems are detected earlier. Real-time alerts, condition monitoring, and predictive maintenance help teams fix issues before they interrupt production. | • 30–50% reduction in unplanned downtime • Earlier detection of equipment failures • Fewer costly last-minute disruptions |

| 2. Better visibility across production | Teams gain a real-time view of machine status, performance, quality trends, and bottlenecks. Everyone works from the same, up-to-date information. | • Improved decision-making • Faster issue resolution • Less time spent searching for information |

| 3. Higher productivity and throughput | Connected data helps balance workloads, stabilize production cycles, and eliminate bottlenecks. | • 10–20% productivity increase • Better line performance • More predictable output |

| 4. Improved quality and fewer defects | Continuous data collection makes it easier to detect deviations early, adjust processes, and prevent defects from spreading. | • Higher first-pass yield • Reduced scrap and rework • More consistent product quality |

| 5. Stronger maintenance and asset reliability | Maintenance teams receive real-time insights into machine health and performance. Work orders can be triggered automatically based on sensor data. | • 20–40% lower maintenance costs • Longer equipment lifetime • Fewer emergency repairs |

| 6. Better coordination between teams | Production, quality, and maintenance share the same data and alerts, improving teamwork and reducing delays. | • Fewer communication gaps • Faster cross-team responses • Smoother shift-to-shift handovers |

| 7. Stronger supply chain and planning accuracy | Real-time production data supports more accurate planning, inventory control, and logistics decisions. | • Fewer shortages and delays • More reliable schedules • Improved on-time delivery |

| 8. Increased safety and compliance | Automated monitoring and digital instructions support safer operations and help maintain compliance. | • Faster response to unsafe conditions • Better adherence to standards • Reduced risk of human error |

Connected manufacturing use cases across different sectors

Connected manufacturing delivers its strongest value when the concept is applied to real operations, real equipment, and real production challenges. Below are examples from industries where Process Genius has already helped companies modernize their visibility, monitoring, and decision-making with connected data and 3D Digital Twin technology.

Heavy-duty manufacturing and lifting operations rely on reliable equipment, precise load handling, and high safety standards.

Heavy industry & Lifting equipment

Connected manufacturing supports this by:

- Integrating crane telemetry, load data, and usage cycles

- Enabling predictive maintenance for lifting systems

- Monitoring wear components and safety-critical parts

- Supporting safe operations with digital alarms and status reporting

Example:

Konecranes uses the 3D Digital Twin to visualize crane performance, monitor equipment status, and improve both reliability and operator safety.

Outcomes:

Higher equipment uptime, safer operations, fewer unexpected failures.

Metalworking and machining plants depend on precise processes and stable production conditions.

Metal manufacturing, CNC, and fabrication

A connected environment brings benefits such as:

- Real-time monitoring of CNC machines and machining cells

- Early detection of process deviations

- Visibility into energy use, vibration, and machine loads

- Integration of material flow, work orders, and quality data

Example:

Mecmetal uses connected data and the 3D Digital Twin to track production stages, identify bottlenecks, and improve quality consistency across different product lines.

Outcomes:

Reduced scrap, faster troubleshooting, more predictable throughput.

Painting, coating, and surface treatment systems demand stable environmental conditions and efficient energy use

Industrial surface treatment & Coating systems

Connected manufacturing helps by:

- Monitoring airflow, temperature, pressure, and chemical consumption in real time

- Tracking the health of pumps, filters, fans, and curing systems

- Managing ventilation efficiency and ensuring consistent coating quality

- Visualizing equipment behavior for easier troubleshooting

Example:

Pekotek uses the 3D Digital Twin to monitor entire coating systems visually and to reduce downtime related to pumps, ventilation, and surface-treatment processes.

Outcomes:

Higher coating consistency, reduced rework, improved energy efficiency.

Food manufacturers like Snellman manage sensitive processes where freshness, hygiene, and traceability are critical.

Food production & Process industry

A connected manufacturing environment helps to:

- Monitor temperature, humidity, and environmental conditions in real time

- Track production stages and raw material flow through every step

- Ensure equipment cleanliness and hygiene compliance

- Detect anomalies early in processes where timing and precision matter

- Optimize energy usage in refrigeration and processing equipment

Example:

Snellman uses the 3D Digital Twin to visualize production environments, monitor conditions, and ensure consistent, safe processing throughout the plant.

Outcomes:

Higher food safety, stable product quality, lower waste, and better control of sensitive production conditions.

Mantsinen produces large material-handling equipment and must ensure reliability, safety, and predictable performance across complex production and testing operations.

Heavy equipment manufacturing & Logistics

A connected manufacturing enables:

- Monitoring cranes and heavy lifting equipment during production and testing

- Tracking hydraulic systems, load cycles, and stress conditions

- Visualizing assembly stages and equipment location on the factory floor

- Identifying production bottlenecks and optimizing workflows

- Improving safety by monitoring critical components in real time

Example:

Mantsinen uses the 3D Digital Twin to gain real-time visibility into assembly conditions, equipment behavior, and factory-wide workflows.

Outcomes:

More efficient assembly, improved quality assurance, and safer heavy-equipment operations.

Across all these industries, the 3D Digital Twin acts as the unifying layer that strengthens connected manufacturing by:

- Presenting machines, assets, and systems in a visual, real-time model

- Showing alarms, process deviations, and load conditions instantly

- Helping teams understand where problems originate — and why

- Making cross-team collaboration easier with a shared operational picture

- Combining machine, maintenance, quality, and environmental data in one place

Whether it’s crane operations, CNC machining, coating systems, or utility plants, the Digital Twin makes connected manufacturing practical, intuitive, and scalable.

The Connected Manufacturing roadmap

Transforming a factory into a connected manufacturing environment doesn’t need to happen overnight. Most companies move step by step — starting from where they are today and gradually building toward a more integrated, real-time way of working.

Below is a simple, practical roadmap that helps teams move toward connected manufacturing in a structured and manageable way.

Step 1 — Understand your current situation

Every factory has a different starting point. Before adding new tools or technologies, it’s important to know how things work today:

- Which machines are already capable of sending data

- Whether existing machine data could be integrated using standards like OPC UA

- What systems are in use (MES, ERP, CMMS, QMS, SCADA)

- Where manual work still happens

- How teams communicate day to day

- What KPIs matter most and how they’re tracked

This first step reveals the gaps and opportunities.

Step 2 — Connect machines and sensors (M2M)

Before connecting equipment, it’s important to understand what information is missing today and which data points are critical for monitoring. Some gaps can be filled by adding simple IIoT sensors, while others may require connecting PLCs, robots, or automation systems directly.

Once these needs are clear, the next step is choosing how to bring the data into your environment:

- Can IIoT sensors provide the missing measurements?

- Do certain machines need deeper integration through PLCs or controllers?

- Is a separate data-integration platform needed, or can the data flow directly into a unified system that also handles visualization and workflows?

In many cases, data can be brought directly into Genius Core, eliminating the need for an additional integration layer and reducing system complexity.

Typical actions in this step include:

- Adding IIoT sensors for temperature, vibration, energy, or throughput

- Connecting PLCs, robots, and automation equipment

- Capturing real-time data from critical machines

- Using edge devices when needed to normalize or preprocess signals

This builds a reliable stream of machine data that future steps rely on.

Step 3 — Integrate your core systems and bring their data into the 3D Digital Twin

Once machine data and digital workflows are in place, the next step is to bring everything together. In most factories, critical information is scattered across different systems — MES, ERP, CMMS, QMS, SCADA, WMS, and even spreadsheets. Each system knows its part of the process, but none of them show the full picture on their own.

This step is about making these systems work together and integrating the right data into the 3D Digital Twin, so the factory finally gets one clear, visual view of what’s happening.

If you want a straightforward explanation of how to approach Digital Twin implementation, you can explore our ground-level guide here.

What happens in this step:

- Identify which systems contain the most important operational data

- Set up integrations between them so information flows automatically

- Define which data points teams actually need for daily decision-making

- Feed this data into the 3D Digital Twin, where it’s shown in the context of real machines, areas, production lines, and workflows

Why it matters:

- No more scattered, out-of-sync data

- Teams don’t need to switch between multiple dashboards and applications

- Less manual data entry and fewer errors

- Faster communication between departments

- A single operational truth for the entire factory

The result:

You get one visual environment where all essential data from your core systems comes together. In simple terms: everything that used to live in separate tools is now visible in one 3D view.

Step 4 — Digitalize operator workflows (M2H)

Once machine data and data from core systems is flowing, the next priority is supporting the people who keep the factory running. This means digitizing daily tasks and improving how teams communicate with each other. In most factories, paper instructions, manual reporting, and scattered communication channels slow things down — connected manufacturing solves this.

This step includes:

- Replacing paper checklists with digital instructions

- Sending real-time alerts and guidance to mobile devices

- Showing live KPIs at workstations and team areas

- Using digital shift handovers and shared dashboards

- Routing tasks and escalations to the right people instantly

- Improving coordination between operators, quality, and maintenance

Digitizing workflows helps teams react faster, stay aligned, and work with the same information.

Step 5 — Scale your connected model and continuously improve

Once your systems, machines, workflows, and data streams are connected and visualized in the 3D Digital Twin, the next step is to expand what works. Instead of treating connected manufacturing as a one-off project, this phase is about scaling it across the factory — and then using real-time insights to keep improving over time.

What happens in this step:

- Add new production lines and equipment into the connected model

- Extend integrations to additional systems and processes

- Standardize workflows across teams and departments

- Expand the 3D Digital Twin to more areas or even multiple sites

- Compare performance between lines, shifts, or factories

- Use real-time anomaly detection to spot trends and improvement areas

Why it matters:

- Consistency improves across the organization

- Teams work using the same tools and the same information

- Operational best practices can be replicated

- Performance gaps become visible and easier to fix

- Improvements don’t stay isolated — they scale

The result:

Connected manufacturing becomes part of everyday operations, not a one-time initiative. As the model grows, the factory becomes more predictable, more transparent, and easier to optimize. Over time, real-time data and long-term trends help teams reduce waste, improve cycle times, stabilize quality, and reach better overall efficiency — across every line and every site.

Connected manufacturing common challenges

Even though connected manufacturing delivers strong benefits, it also comes with challenges that organizations must address early on. These challenges are normal and expected — what matters is having a clear strategy for overcoming them. Below are the most common barriers manufacturers face and simple ways to navigate each one.

| Challenge | What it means | How to overcome it |

| 1. Data silos and inconsistent information | Data is scattered across machines, spreadsheets, and disconnected systems. Teams work from different information, slowing down decisions. | • Integrate systems step by step (MES, ERP, CMMS, QMS, SCADA) • Build a unified data layer • Use a 3D Digital Twin to centralize data in one place • Standardize data collection and naming |

| 2. Legacy equipment and limited connectivity | Older machines lack sensors or networking, making it hard to capture data. Replacing them is costly and unrealistic. | • Add IIoT sensors to critical assets • Use edge gateways to collect machine signals • Integrate with existing PLCs where possible • Start with high-impact assets, then expand |

| 3. Cybersecurity risks in a connected environment | More connectivity increases exposure to cyber threats, especially when IT and OT begin to interact. | • Implement a zero-trust security approach • Segment IT and OT networks • Use encrypted communication and secure protocols • Apply role-based access control and identity management |

| 4. Change management and workforce adoption | New tools and data flows may overwhelm operators and technicians. Resistance is common without clear guidance. | • Start with simple use cases • Train workers using hands-on, practical sessions • Provide clear digital workflows and instructions • Use the Digital Twin to make changes intuitive • Celebrate small wins early |

| 5. Fragmented tools and poor system integration | Production, maintenance, and quality rely on separate systems that don’t communicate. This creates delays and duplicate work. | • Connect key systems one by one • Use standard APIs and integration platforms • Build workflows that automate data exchange • Use the Digital Twin as the central visualization layer |

| 6. Difficulty proving ROI early | Leaders want fast results, but early pilots may not show full value until multiple areas are connected. | • Start with a focused pilot area • Track simple metrics (downtime, cycle time, deviations) • Show quick operational wins • Expand gradually based on evidence • Use Digital Twin visuals to communicate progress |

| 7. Too much data, not enough insight | Once everything is connected, teams may face “dashboard overload” without understanding what data really matters. | • Define core KPIs • Use analytics and alerts to highlight priorities • Avoid displaying unnecessary raw data • Use the Digital Twin to place data in real-world context |

| 8. Scaling across multiple sites | A solution that works in one plant may not scale easily due to different machines, workflows, or maturity levels. | • Create a standard connected-manufacturing template • Use repeatable integration practices • Apply consistent training methods • Deploy the Digital Twin across sites as a unified interface |

Connected manufacturing is no longer a vision for the future — it’s a practical way to run a factory today. When data flows freely between machines, systems, and people, operations become clearer, faster, and more predictable. Teams stop fighting fires and start managing improvements. Planning becomes more accurate, quality becomes more stable, and maintenance becomes proactive instead of reactive.

But as this guide shows, simply connecting equipment is not enough. Factories need a way to bring everything together — machine data, system data, operator workflows, maintenance events, and quality insights — into one shared operational picture. This is where the real value emerges: when every role, from operators to leadership, can see the factory as it truly is and make decisions based on real-time facts rather than assumptions.

The 3D Digital Twin makes this possible. It simplifies industrial data, removes fragmentation, and helps teams understand what’s happening and why. Instead of navigating multiple dashboards or chasing information across systems, teams see everything inside one clear visual model. This makes connected manufacturing not just achievable, but manageable and scalable.

Whether you’re in heavy industry, high-precision machining, food production, or surface treatment, the path toward connected manufacturing follows the same logic: start with what you have, connect what matters, visualize what’s important, and scale what works. The result is a more resilient, transparent, and efficient way of operating — one that grows stronger over time as the data behind it becomes richer.

If you want to explore how other manufacturers have modernized their operations, or see what connected manufacturing looks like through real customer examples, you can browse more references and success stories anytime.

Digital Marketing & Business Specialist