A single view for production, sales and production planning – Premetec Oy

Premetec, chosen as company of the year by entrepreneurs in Outokumpu, Finland, is doing extremely well despite the exceptional conditions. The company has faced new requirements, and has been solving them together with Process Genius Oy.

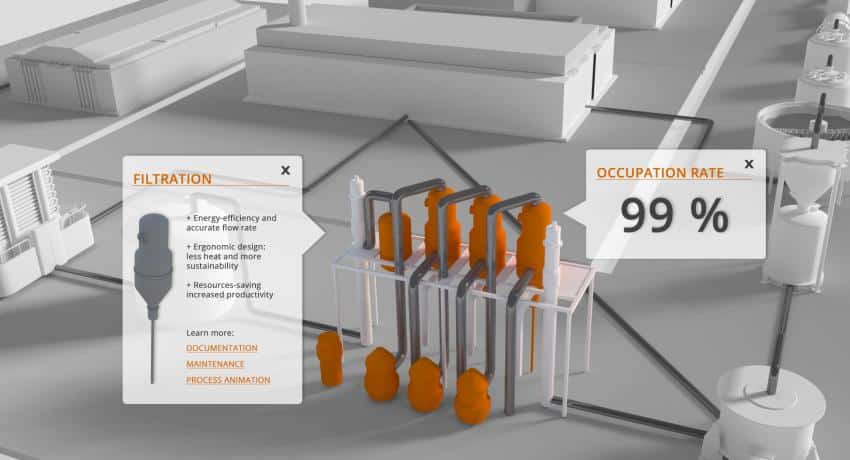

“Customers are increasingly interested in the origin of materials and their traceability,” says Paavo Linna, CEO of Premetec. The company provides its customers with the information they need as part of a global digital supply chain. The digital twin application provided by Process Genius Oy has enabled transparency in Premetec’s operations. With Genius Core™, the origin of the materials used has been traceable.

Traceability and responsible production of material a must

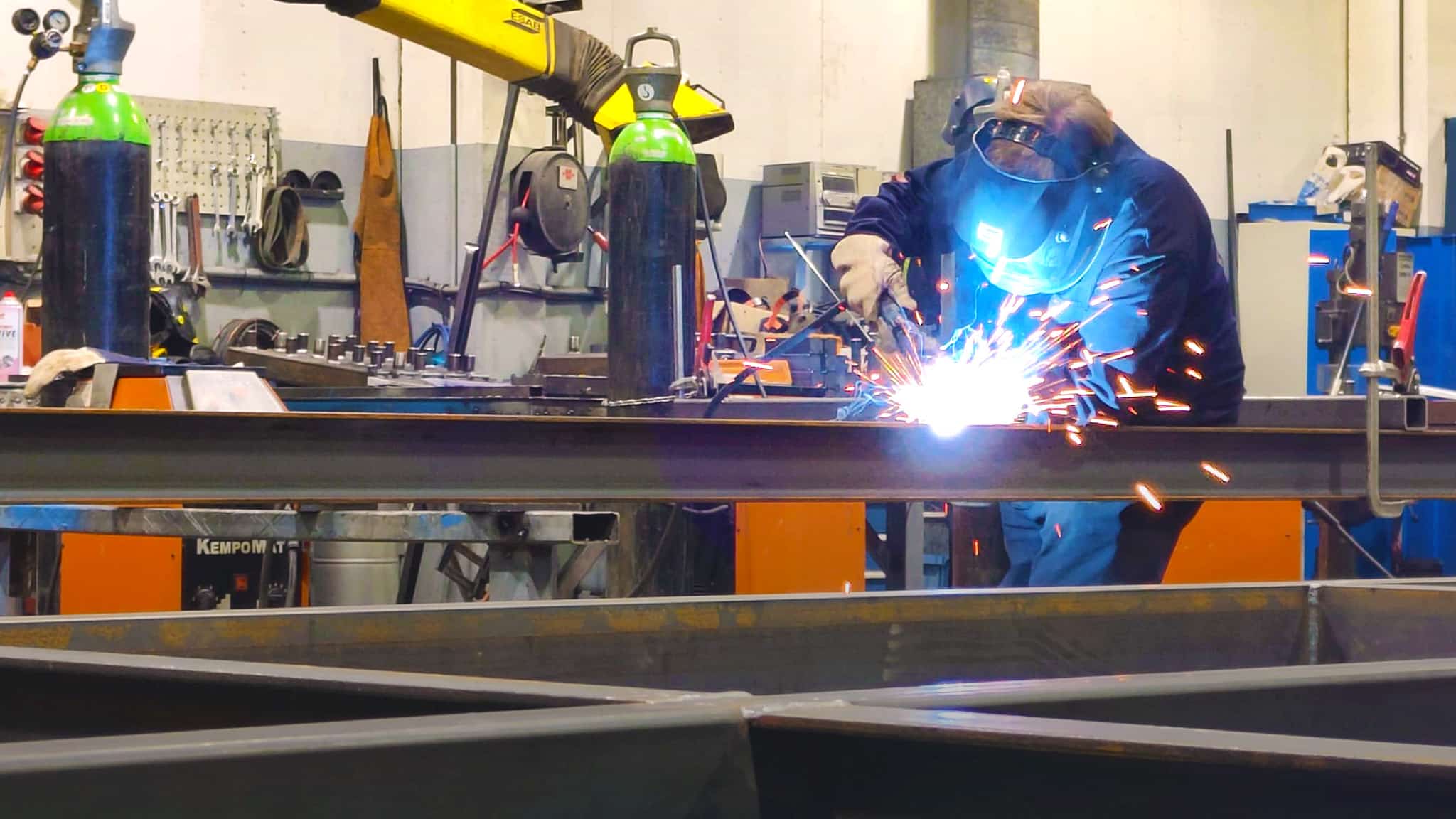

Premetec manufactures metal and plastic parts, sub-assemblies and tooling for the process and manufacturing industries with Toolman by Premetec. According to Linna, Premetec “picks up where others leave off”. The aim is to serve customers quickly, reliably and productively – even with challenging materials. If necessary, the client company is also supported in designing products and developing their manufacturability.

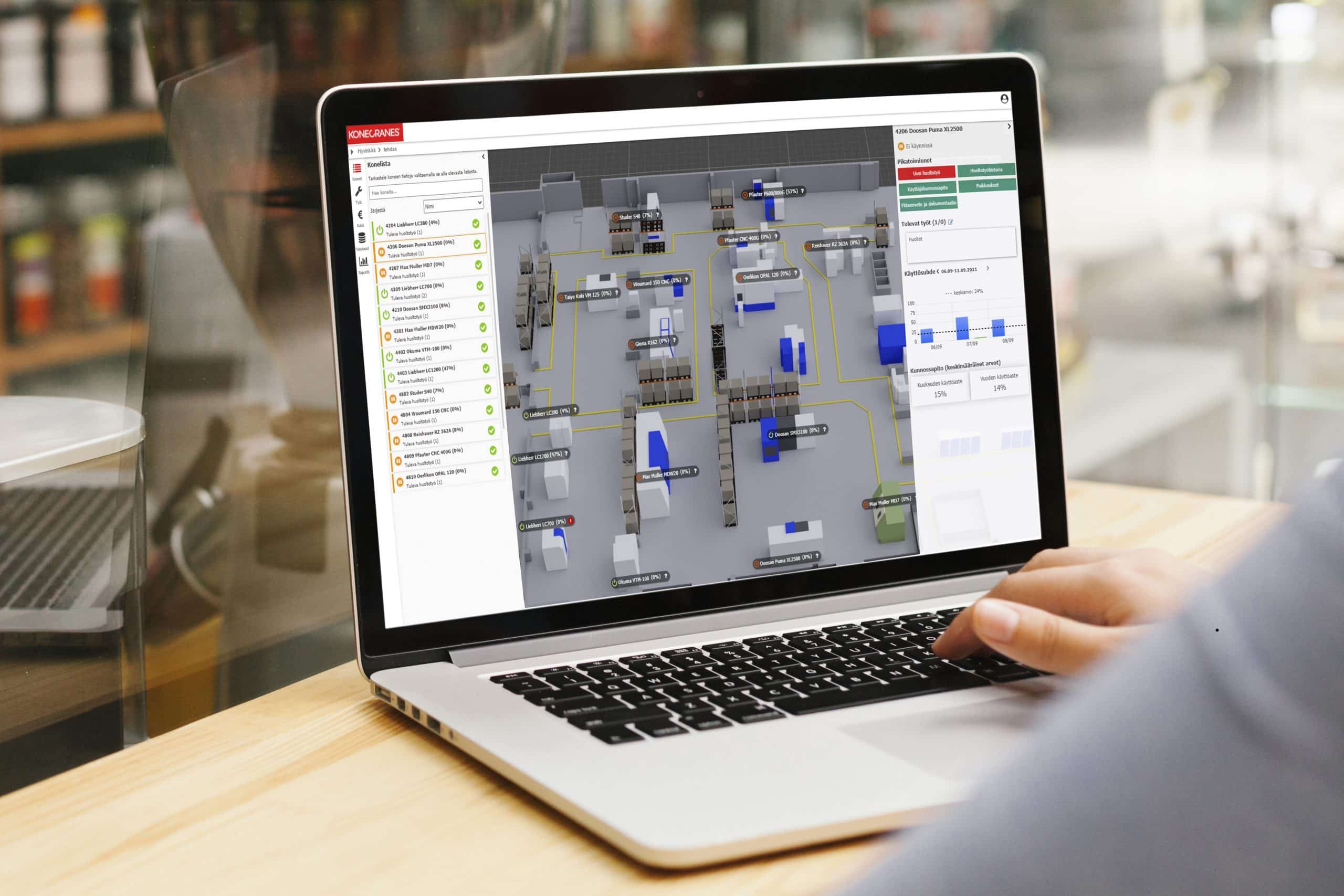

Linna is pleased that they have been among the first to start measuring and digitizing their production, giving them a competitive advantage. Premetec also uses Genius Core 3D Digital Twin to monitor security of supply and production load.

Instead of heavy ERP solutions, we wanted visual workflow control with which changes can be made quickly and easily. Our goal was also to make data easily available for everyone.

Real-time production information at a glance

At Premetec, we constantly invest in the functionality of the working environment. A key element in the smooth running of production is the visual control board, which allows you to see important things at a glance. According to Jorma Martikainen, Production Manager, the dashboard makes it easier to manage operations.

A workflow control screen must be so clear that it leaves you in no doubt. Any ambiguity causes moving around and increases the risk of accidents.

A single view for production, sales and production planning

All relevant information is shown in a single view for production, sales and production planning. Genius Core’s view shows what kind of load is in production, what the next job is and where the raw materials are. Through the platform, staff can contact each other if there are any problems. Linna believes that many companies would benefit from both the single view dashboard and digital twin in general. It can help avoid unplanned production stoppages and improve production efficiency.

Process Genius is constantly developing the platform in collaboration with its customers. When asked what additional features he would like to see next, Linna mentions an interface for the client to use. “Customers would be able to track their own order and this would further increase transparency,” he says.

Other customer stories

Pekotek: White Labeling allows Pekotek’s end customers to benefit from cost savings and predictive maintenance capabilities provided by the 3D Digital Twin

Taking day-to-day management processes to a new level – Konecranes Smart Factory

Working together to develop service business – Flowrox and Process Genius

All the information you need at one glance. One platform.

Want to know more about our solution for your organization? Please drop us a line and we’ll be in touch!