Focusing employee resources on what matters most with Digital Twin

Even in times of economic uncertainty, an industrial machinery company is committed to investing in supporting its staff and allocating resources properly. The aim is to ensure both current growth and future growth potential through the digital twin.

Challenge

In times of economic uncertainty, companies are often faced with difficult decisions on cost reduction and resource allocation – and the pressure to improve their market position is increasing. Manufacturers cannot afford any problems that could disrupt productivity when expectations are so high and market conditions are difficult.

In challenging times, investing in smart industrial technologies such as digital twins often proves to be a smart corrective move, allowing companies to emerge even stronger than in times of uncertainty with just one system.

Solution

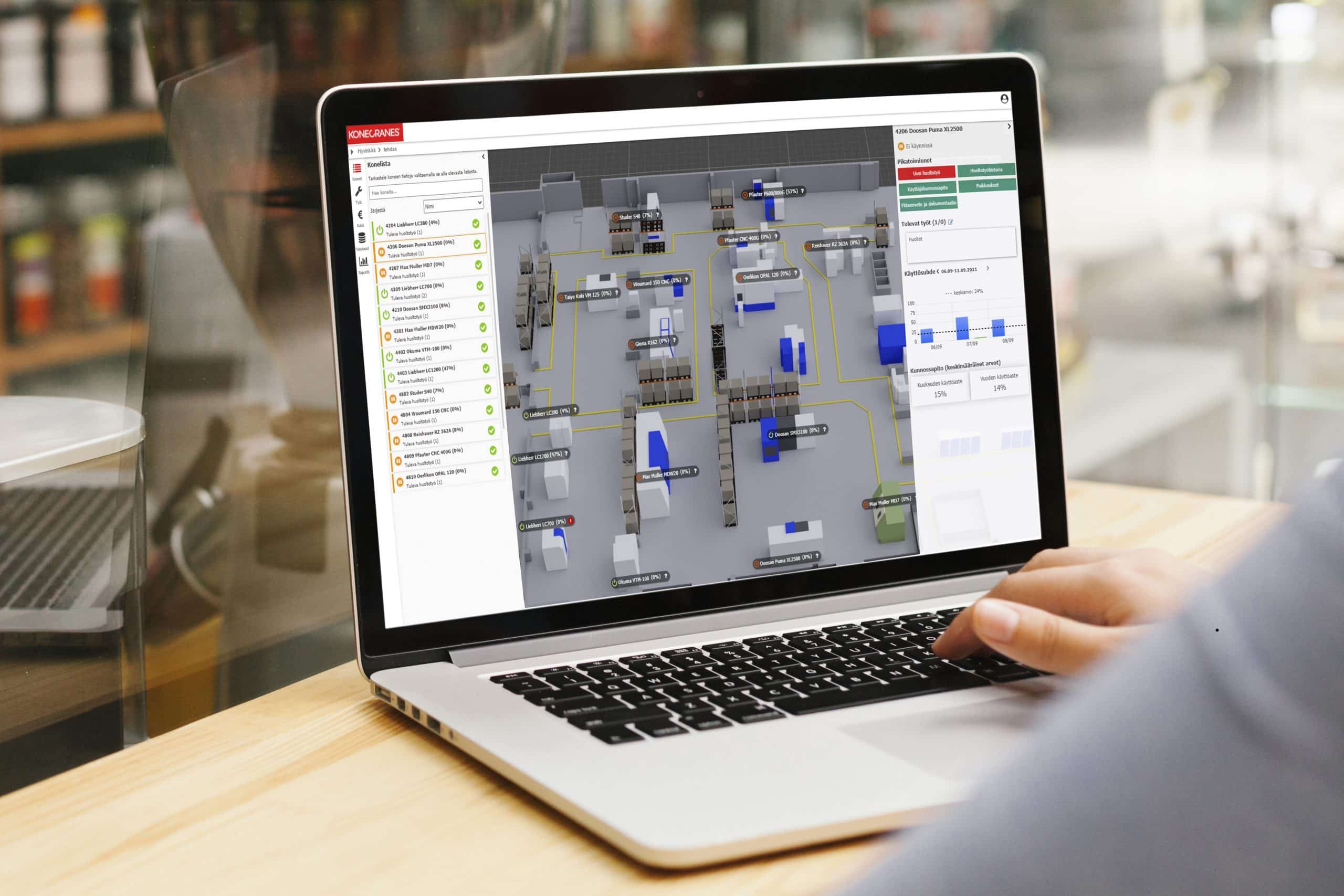

By leveraging advanced technologies such as OPC UA, data analytics and the Internet of Things (IoT), the Genius Core™ 3D Digital Twin platform offers manufacturing industry operators significant benefits that go beyond mere cost savings.

One of the main reasons why the 3D Digital Twin is crucial to a company in a downturn is its ability to streamline operations. Traditional inspection and maintenance methods can be time-consuming, inefficient and expensive. With Genius Core™, the company now collects and manages real-time data from existing data sources – both OPC UA and other sensors embedded in physical machines – and can analyse it to gain valuable insights.

OPC UA is a multi-platform, open source industrial automation and data transfer standard that enables data transfer from sensors to cloud applications. Read more: frequently asked questions about OPC UA.

This real-time feedback loop allows the company to identify and address potential problems before they become costly issues. This effectively minimises maintenance downtime and helps to optimise maintenance schedules and maximise machine performance.

3D digital twins offer the opportunity to significantly reduce costs across different business activities. By creating virtual models of production lines, companies can identify inefficiencies, bottlenecks and areas for improvement. This enables informed decision-making and process optimisation to reduce waste, improve resource efficiency and increase overall operational effectiveness. Ultimately, these cost savings can help businesses cope with difficult economic situations while maintaining their financial health.

The primary benefit of Genius Core™ for your business is its ability to increase employee productivity. By providing employees with access to real-time information and forecasts, a company can empower its employees to make informed decisions and take proactive action immediately. For example, by monitoring and analysing production line data, Genius Core™ enables workers to quickly identify problems, correct faults and take corrective action quickly. This not only minimises disruption, but also helps employees to focus on essential tasks and contribute effectively to the success of the business.

Key outcomes

Investing in the digital twin is not just about weathering the recession, it’s about ensuring the long-term success of your business. By adopting 3D Digital Twin, your business too can gain an almost immediate competitive advantage and stay ahead of the curve.

All the information you need at one glance. One platform.

Want to know more about our solution for your organization? Please drop us a line and we’ll be in touch!