What Is Remote Monitoring? A guide for modern enterprises

This guide breaks down what remote monitoring is and why it matters for today’s businesses. It shows how tools like IoT sensors and real-time data help teams work smarter, cut downtime, and stay on top of their systems from anywhere. You’ll also see how a web-based 3D Digital Twin brings everything together in one easy-to-use view—making it simple to spot problems and keep things running smoothly.

In today’s connected world, remote monitoring has become essential for businesses that want to keep an eye on their systems, assets, and operations from anywhere. Whether it’s industrial equipment, healthcare tools, or IT systems, remote monitoring gives teams the real-time data and visibility they need to improve performance, cut downtime, and keep everything running smoothly.

An exciting development in this space is the rise of 3D Digital Twins. These dynamic digital models mirror physical assets in a virtual environment, but more importantly, they bring together data from multiple systems and departments into one unified view. This breaks down data siloes and allows teams to see the full operational picture in real time. With 3D Digital Twins, remote monitoring becomes more integrated, intuitive, and powerful—helping businesses detect issues faster, collaborate better, and make smarter decisions from a single source of truth.

This guide breaks down what remote monitoring is, how it works, its biggest benefits, where it’s used, and the technologies that make it all possible.

What is Remote Monitoring?

Remote monitoring is the use of technology to watch, gather, and analyze data from equipment or systems—without being there in person. These systems use connected devices, sensors, and remote monitoring software to keep track of performance and system health in real time.

In most organizations today, there’s a growing number of tools in play—ERPs, MES systems, IoT platforms, fleet management systems, even shift planning tools for workers. Each generates valuable data, but when these systems operate in silos, it becomes overwhelming and hard to manage. That’s why modern remote monitoring isn’t just about collecting data—it’s about connecting the dots. The right solution helps bring all this information together in a way that’s clear, balanced, and actually useful for making decisions.

How Remote Monitoring Works :

Remote monitoring systems pull in data from IoT sensors and devices, then send that information through the internet or a private network to a cloud-based or local platform. From there, the data gets analyzed so teams can take action if needed.

A remote monitoring system typically includes:

- IoT sensors: Measure things like temperature, vibration, or pressure

- Connectivity modules: Securely send the data

- Remote monitoring software: A dashboard to view analytics, get alerts, and track trends

- Cloud infrastructure: Stores and processes large amounts of real-time data

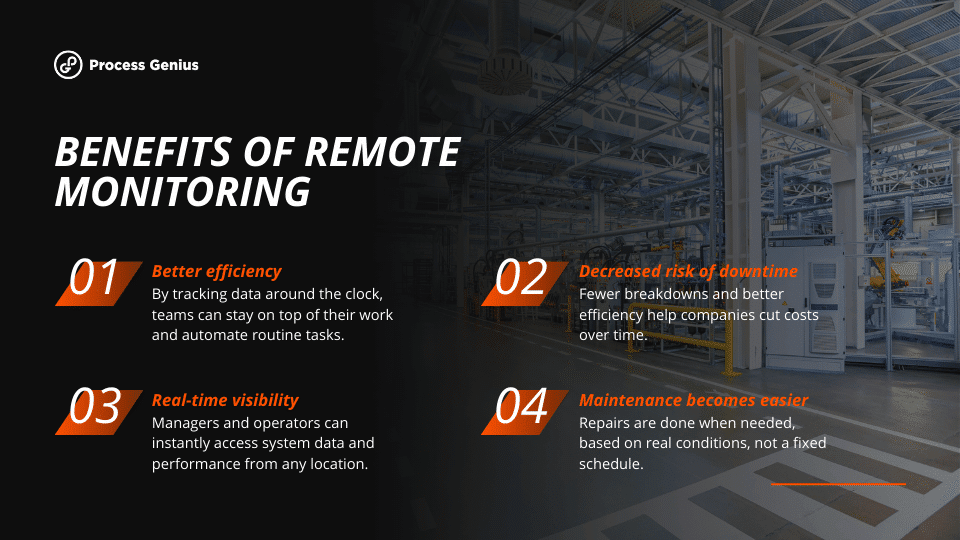

Benefits of Remote Monitoring

- Better efficiency – Tracking data 24/7 helps teams take control over workflows and automate repetitive tasks.

- Lower risk of downtime – Real-time alerts and predictive maintenance tools help spot problems before they become serious.

- Lowe costs – With fewer breakdowns and more efficient systems, companies save money over time.

- Real-time visibility – Managers and operators can view system data and performance instantly, from anywhere.

- The maintenance is easier – Instead of following a fixed maintenance schedule, companies can make repairs when they actually need to—based on what’s really happening.

Common applications & Use cases

Remote monitoring is used in all kinds of industries. Here are a few of the most popular applications:

1. Manufacturing and Industrial Equipment

Industrial remote monitoring helps plant managers oversee machines, track output, and keep workers safe. By integrating 3D Digital Twins, manufacturers can create a real-time virtual model of their factory floor. This provides a comprehensive view of all operations in one place, combining data from equipment, sensors, and maintenance systems. With this level of visibility, teams can quickly identify bottlenecks, monitor energy usage, and respond to anomalies without being on-site. It also helps improve collaboration between departments by giving everyone access to the same up-to-date operational data. A good example of this in action can be seen in how we use 3D Digital Twin technology to unify siloed data into a clear, interactive overview of factory operations.

2. Healthcare

Remote patient monitoring systems let healthcare teams watch vitals and manage chronic conditions outside of hospitals or clinics.

3. What Smart Buildings & Facilities Management

Facility managers use remote monitoring to track HVAC, lighting, and security systems—saving energy and improving safety. A real-world example is the Elisa properties project by Process Genius, where 3D Digital Twin technology is used to unify data from various building systems—like energy consumption, indoor air quality, and occupancy—into one interactive interface. This makes it easier to manage large-scale properties remotely, improving efficiency, transparency, and overall decision-making.

4. IT Infrastructure

IT departments rely on remote monitoring software to keep tabs on servers, networks, and databases—ensuring systems stay online and running smoothly.

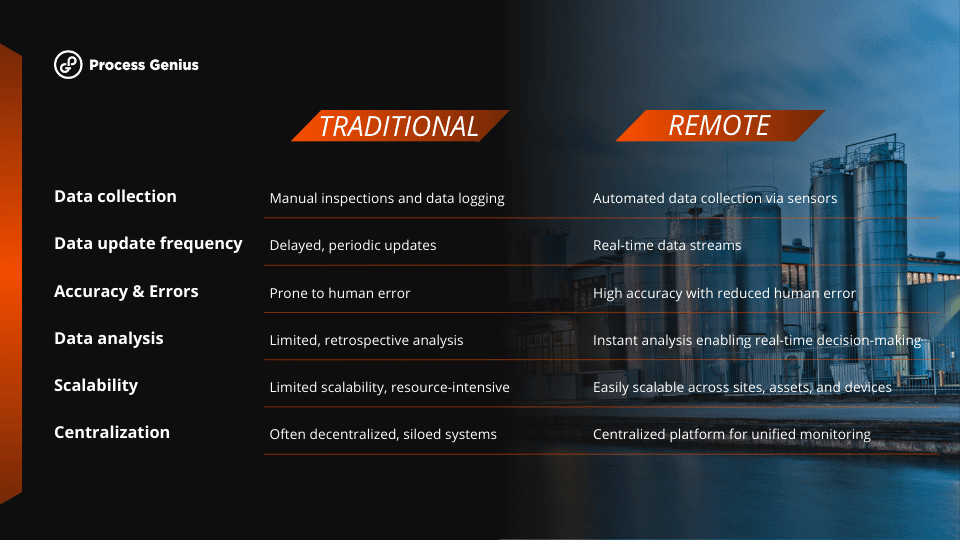

Remote monitoring vs. Traditional monitoring

Manual vs. Automated

Traditional monitoring often involves manual inspections, data logging, and delayed reporting. Remote monitoring automates these processes through sensors and cloud platforms, reducing errors and enabling continuous, unattended data collection.

Real-Time Data & Accuracy

Remote monitoring systems provide real-time data streams, ensuring that information is always current and actionable. This level of accuracy allows teams to respond to incidents quickly and with confidence, making real-time data analytics tools essential in fast-paced environments.

Scalability

Modern remote monitoring and management solutions are designed to grow with your operations. Whether you’re managing a single site or a global network, these systems allow you to monitor multiple assets, devices, or locations simultaneously—all from a centralized platform. This scalability is especially powerful when combined with 3D Digital Twin technology, offering a unified view of operations across physical and digital spaces. A key enabler of this integration is seamless system connectivity, such as the integration capabilities offered by Process Genius, which bring together data from various tools and platforms into one coherent monitoring environment.

Key technologies behind Remote Monitoring

IoT Sensors & Gateways

Sensors collect operational data from machinery, infrastructure, or environments. Gateways then transmit this data securely to a central platform for processing and visualization. These components form the backbone of any remote monitoring system, especially in industrial settings where accurate, real-time data is crucial for performance and safety. A great example of how this works in practice is shown in this article, which explores how combining IoT, AI, and 3D Digital Twins elevates predictive maintenance and monitoring in modern manufacturing environments.

Cloud-Based Monitoring Platforms

Cloud-based platforms like Genius Core play a key role in remote monitoring by enabling centralized access to real-time data from any location. These platforms offer scalability and flexibility, allowing businesses to manage large volumes of data while reducing the need for on-premise infrastructure.

Remote Monitoring Software

Remote monitoring software acts as the control center of the system. It presents insights through interactive dashboards, delivers automated alerts, and enables historical trend analysis. A well-designed remote monitoring software solution should also support real-time data analytics tools and integration with third-party platforms to break down data silos.

Real-Time Data Processing & Analytics

Modern remote monitoring and management tools rely on real-time analytics platforms to process incoming data instantly. These systems not only alert users about anomalies or faults but also help predict failures before they occur. By analyzing large volumes of streaming data, businesses gain valuable insights that improve decision-making, optimize operations, and reduce downtime.

Choosing the right Remote Monitoring solution

When evaluating a remote monitoring solution for your business, consider the following key factors:

Features

Look for key tools like real-time dashboards, automated alerts, and historical data tracking. Advanced remote monitoring and management platforms should also include predictive maintenance capabilities and support for real-time data analytics tools. For example, Pekotek uses a 3D Digital Twin powered by Process Genius to support predictive maintenance across their manufacturing operations. This approach enables them to visualize system performance, proactively manage equipment lifecycles, and reduce unplanned downtime—all through a unified, cloud-based monitoring environment.

Integration

Choose a system that fits well with your current IT or OT setup, and can integrate easily with your existing software stack, including ERP, MES, and asset management platforms. This helps eliminate data silos and ensures a smoother workflow.

Cloud-hosted and web-based

A powerful differentiator in modern remote monitoring solutions is the inclusion of web-based 3D Digital Twin platforms. Unlike traditional local installations, web-based Digital Twins offer accessibility from any device with a browser—no downloads or special software required. This approach allows for real-time visualization of physical assets and operational data in a highly interactive, user-friendly interface. With cross-device compatibility, teams across departments can collaborate more effectively, monitor critical systems remotely, and make decisions faster based on synchronized, visualized data. Web-based twins also support remote updates and easy scaling, making them ideal for enterprises managing multiple sites or distributed teams.

Security & Compliance

Ensure your remote monitoring software follows best practices in cybersecurity, including data encryption, user access control, and regular security updates. It should also comply with relevant regulations and standards in your industry.

Scalability

Your system should grow with your business—adding new devices, users, and remote locations should be simple. Scalable platforms—especially those that work with cloud-based 3D Digital Twin solutions like Genius Core—offer the flexibility needed for future expansion and system complexity.

Remote monitoring is changing the way organizations run their operations. With the right remote monitoring system in place, companies can increase efficiency, cut costs, and respond to problems as they happen.

Whether you’re in manufacturing, healthcare, IT, or facilities management, investing in a remote monitoring solution can help future-proof your business. Check out how other forward-thinking companies have already adopted 3D Digital Twin technology and are seeing measurable benefits—or reach out to us directly with your questions to explore how this approach can work for you.

Digital Marketing & Business Specialist