Process Genius Oy develops factory-level digital twin with Stora Enso

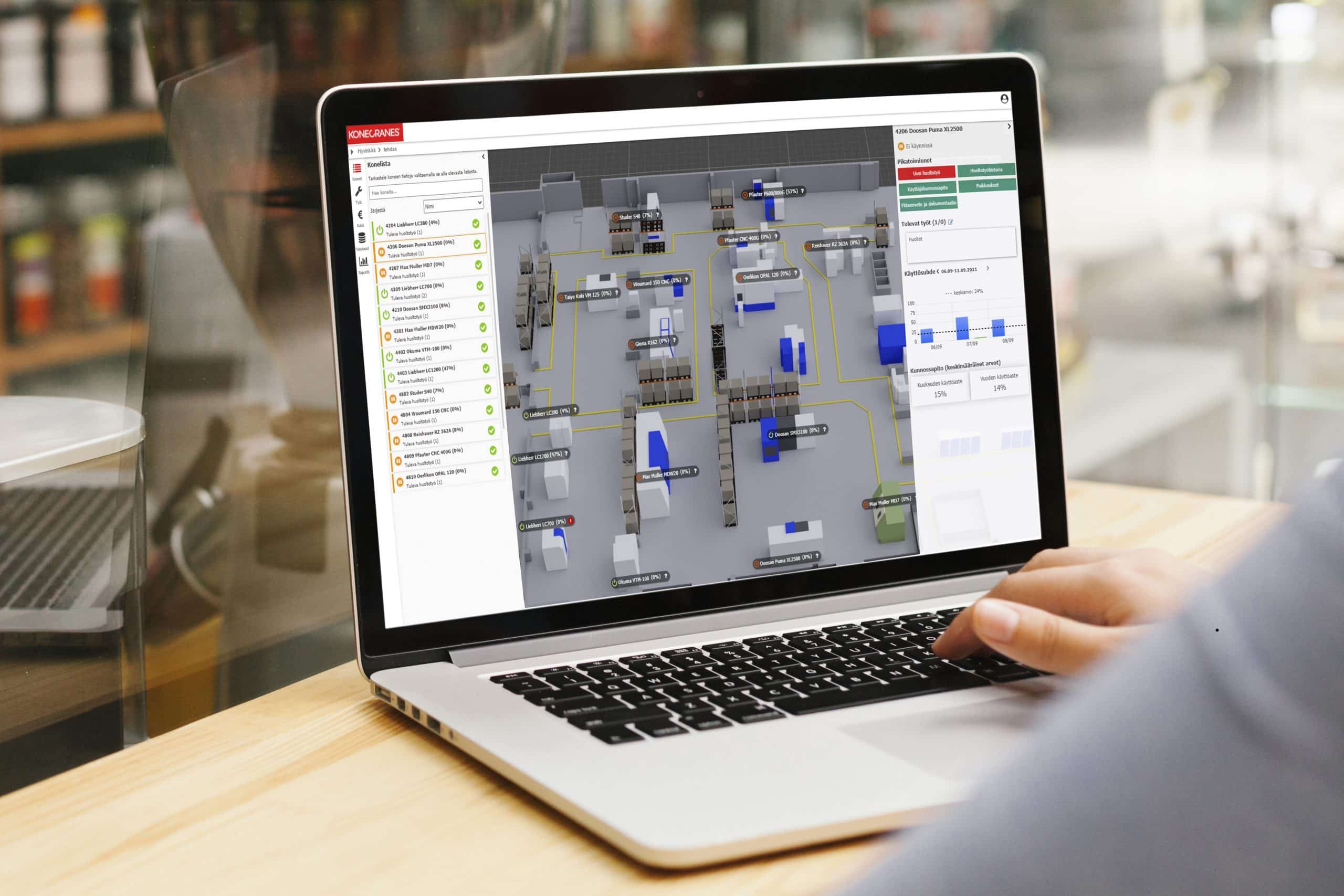

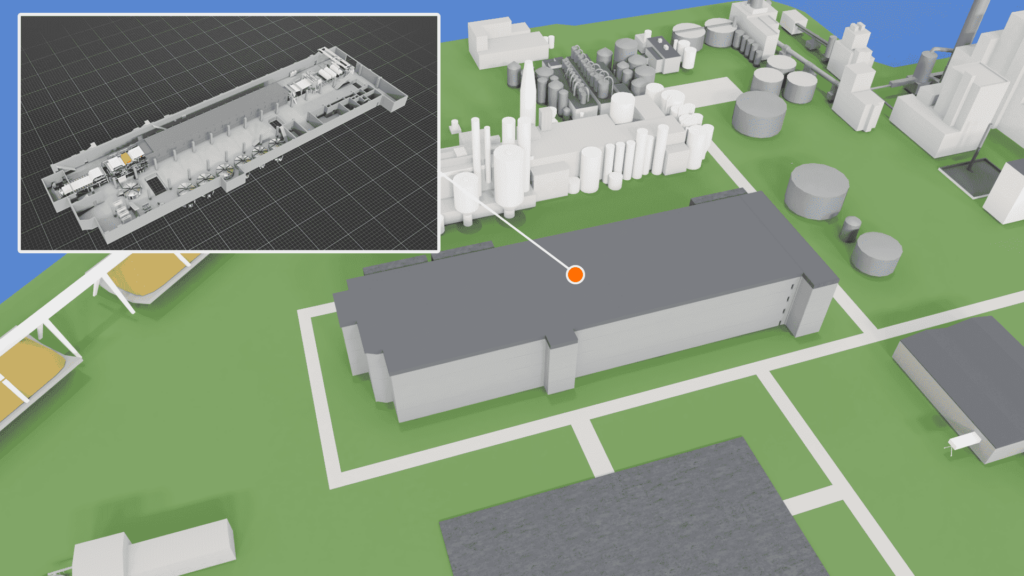

Thanks to factory-level digital twins, the daily ERP of factories has been taken to a new level. As digital twins share a cloud platform, individual factories can be connected to the platform, making it possible to access new features on them.

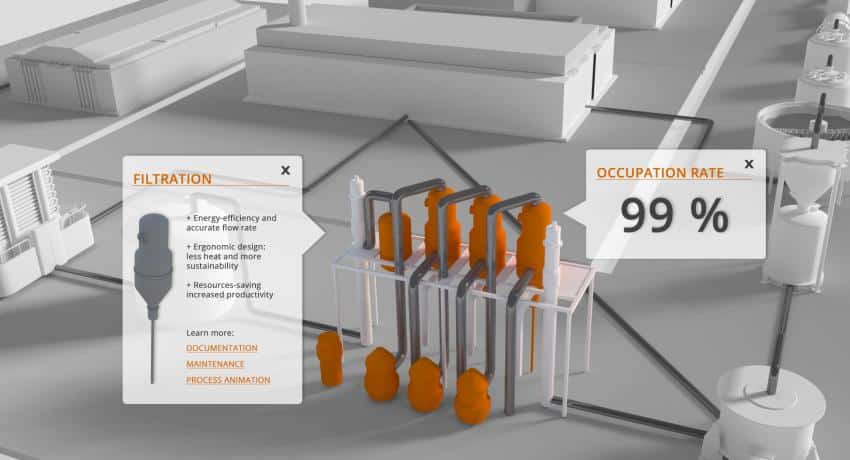

A digital twin can mean many different things. It can be a 3D model of a single detail or a copy of an entire machine, enabling virtually assisted reality or simulation to optimize performance.

“The factory-level digital twins run on a cloud platform, which enables new use cases to be scaled to multiple factories quickly,” says Jani Akkila, CEO of Process Genius Oy.

Process Genius and Stora Enso developed digital twins to improve day-to-day ERP decision-making by visually presenting key information. Digital twins are used to create an understanding of the current situation in factories and what needs to happen next. They also indicate if any parts of the process are behind schedule. It is also important to understand why the current situation is what it is. Accurate and easy-to-understand information on operations helps take decision-making to a new level.

Mitä helpommin tiedot ovat ymmärrettävissä, sitä parempia päätöksiä voidaan tehdä. Elleivät päätösten tekijät tiedä, mitä tiedot tarkoittavat, he eivät myöskään tiedä, miten toimia oikein.

Ennen meidän täytyi käydä läpi satoja rivejä raporttitietoja, mutta nyt riittää, kun vilkaisee tehdastason digitaalista kaksosta saadakseen käsityksen tehtaan tilanteesta.

The factory-level digital twin helps to quickly pinpoint incident locations, such as the sites of security alerts. This is useful in situations where people outside the factory need to know the location of exits, for example. In addition to safety situations, visual information presentation is useful in many other contexts, such as maintenance management, including predictive maintenance and production line performance management.

The digital twin was first tested in one factory. When it proved to work, the digital twins were scaled up to several Stora Enso factories in Finland and abroad.

“The exceptional circumstances have confirmed the vision we have had for years about the benefits of the digital twin for different sectors. We have achieved a good level of technological scalability and have increased our cooperation in international markets. We will continue to work on developing the product with both existing and, ideally, new partners”, Process Genius’ Jani Akkila sums up.

All the information you need at one glance. One platform.

Want to know more about our solution for your organization? Please drop us a line and we’ll be in touch!