A modern approach to industrial monitoring: 3D Digital Twins and robot-based inspections

A modern look at industrial monitoring using 3D Digital Twins and autonomous inspections for safer, smarter, and more reliable operations.

- What is industrial monitoring today?

- Challenges in industrial monitoring

- The role of 3D Digital Twins

- The role of autonomous Robot Dogs

- How Digital Twins work together with Robotic dogs

- Benefits of autonomous industrial monitoring

- Industrial monitoring use cases

- Solar plant monitoring

- Equipment condition tracking

- Machine & production line monitoring

Industrial sites are busy, messy places. You’ve got more connected machines than ever, strict safety rules, and fewer people covering larger areas. Data pours in from sensors, PLCs, SCADA, and maintenance systems—but it’s scattered. When something goes wrong, it can take too long to spot and even longer to fix.

Walk-throughs and manual checks still matter, but they have limits. People can’t be everywhere at once. Night shifts and hazardous zones are hard to cover. Paper notes and siloed dashboards leave gaps. And every unnecessary minute spent near heat, height, chemicals, or moving equipment is a risk—and a cost.

That’s where a modern approach to industrial monitoring comes in: a 3D Digital Twin as the single, real-time view of the plant, and autonomous robot dogs that do the routine rounds. The robots handle the patrols—capturing images, thermal readings, audio, gas levels, and more—while the digital twin pulls all that data together with your existing OT/IT systems. The result is simple: faster detection, fewer blind spots, safer teams, and decisions made on one clear picture of reality. In this article, we’ll show how Process Genius’s 3D Digital Twin and Karelics’s autonomous robots work together to raise the bar for monitoring—without adding complexity for your people.

What is industrial monitoring today?

Industrial monitoring is all about keeping an eye on how your equipment, processes, and environments perform. In simple terms, it means collecting and analyzing data to make sure everything runs safely, efficiently, and without unexpected stops.

Not too long ago, this mostly meant manual inspections—operators walking through the plant with clipboards, checking gauges, and listening for strange sounds. It worked, but it relied heavily on human attention and experience.

Then came the IoT revolution. Sensors, cameras, and smart devices started sending data directly to control rooms. Engineers could finally see what was happening in real time instead of waiting for reports. But even with IoT, information often sits in separate systems—one for machines, another for energy, another for maintenance.

Now, we’re entering the next phase: automation and intelligent monitoring. Digital twins bring all that scattered data together into one interactive 3D view of the factory, while autonomous robots take care of repetitive inspections. It’s monitoring that never sleeps—accurate, connected, and ready to act before problems become downtime. For a deeper look at how remote insights support daily operations, see our article on remote monitoring.

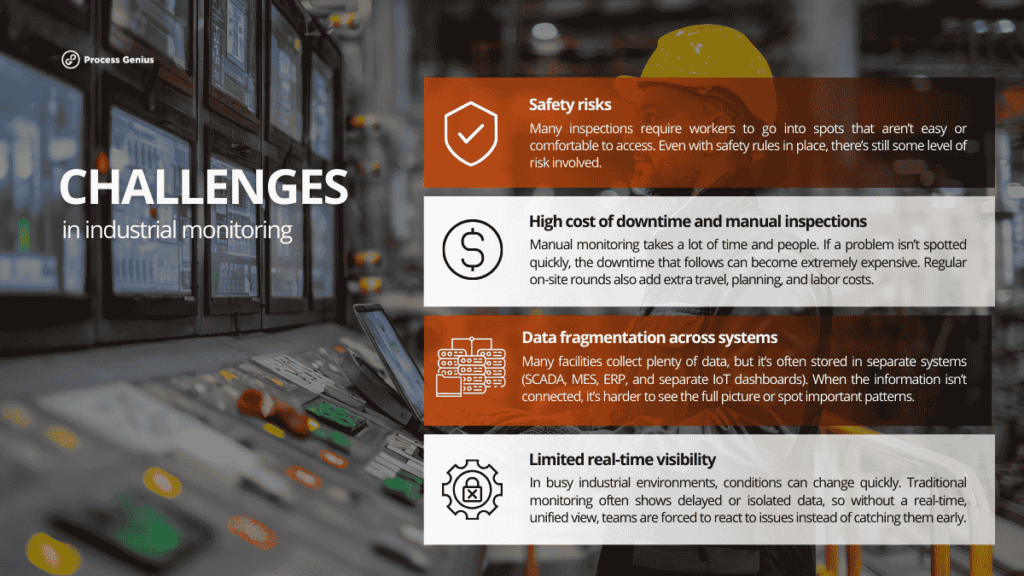

Challenges in industrial monitoring

Even with modern tools, industrial monitoring still comes with its share of challenges. Many of them are tied to the realities of large, busy environments—factories, energy sites, and infrastructure facilities that never stop moving.

1. Safety risks for workers

Industrial inspections often mean sending people into risky or hard-to-reach areas—hot zones, high platforms, or confined spaces. Even when proper safety measures are in place, human presence in these areas increases exposure to hazards. Every inspection that can be done remotely or autonomously is a step toward a safer workplace. Read more on this topic in our article on improving HSE performance.

2. High cost of downtime and manual inspections

Manual monitoring takes time and resources. When an issue is missed or found too late, the resulting downtime can cost thousands per minute. On top of that, sending teams for regular on-site checks adds travel time, coordination, and labor expenses.

3. Data fragmentation across systems

Most facilities already collect massive amounts of data—but it’s often scattered across multiple systems: SCADA, MES, ERP, and IoT dashboards that don’t talk to each other. This fragmentation makes it hard to see the full picture, spot trends, or connect causes with effects. This challenge is closely tied to industrial data analytics, which we have explored in more detail.

4. Limited real-time visibility

In fast-moving industrial environments, things change by the minute. Traditional monitoring systems often provide delayed information or isolated readings. Without a unified, real-time view, teams end up reacting to problems instead of preventing them.

Solving these challenges means connecting data, automating what can be automated, and giving people clear, up-to-date information they can trust. That’s where 3D Digital Twins and autonomous robot dogs step in.

The role of 3D Digital Twins

A 3D Digital Twin turns complex industrial operations into something visual, connected, and easy to understand. Instead of jumping between different dashboards and reports, teams can see the entire facility in one interactive 3D view—updated in real time.

At the heart of the Process Genius platform is data integration. It connects to your existing systems—OT, IT, IoT, sensors, PLCs, MES, and more—bringing all that information together. The result isn’t just another monitoring tool; it’s a unified environment where every asset, machine, and sensor has a place and a purpose.

This unified view gives operators true real-time visualization. You can click on a machine, see its live condition, maintenance history, or even current temperature readings. If something’s off, you’ll know instantly. No more guessing or waiting for reports—the data tells the story as it happens.

And beyond just displaying data, the digital twin helps with early anomaly detection. By comparing real-time data with historical patterns, the user is able to highlight deviations that may signal a problem—overheating, pressure drops, irregular vibrations—before they cause downtime. We cover this topic in depth in our article on real-time anomaly detection in manufacturing.

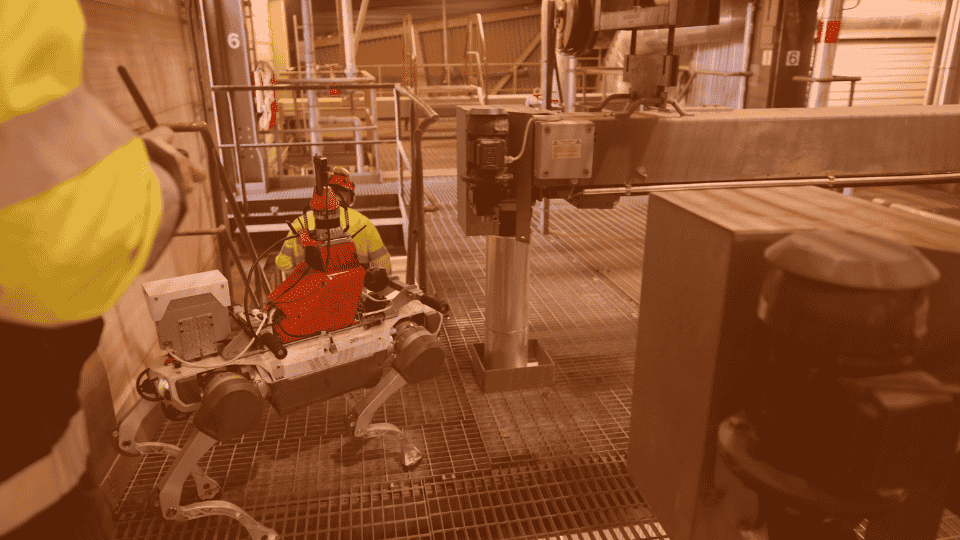

The role of autonomous Robot Dogs

Autonomous robot dogs are becoming a reliable part of everyday industrial monitoring. They’re built to handle long, repetitive inspection routines—moving through production halls, warehouses, and construction sites with steady precision.

Instead of relying on human patrols that can vary from day to day, these robots follow consistent routes and collect the same types of data every time. This makes it easier to compare results, notice gradual changes, and maintain a clear history of how equipment and environments evolve over time.

Their real strength lies in flexibility. Each robot can carry different sensor payloads depending on what needs to be monitored. A thermal camera can reveal overheating components, LiDAR can capture detailed 3D scans of the space, and gas detectors can measure air quality or detect small leaks. Combined, these sensors create a rich layer of information that complements data from fixed industrial systems.

Because they can operate for long hours without interruption, autonomous robots help keep monitoring continuous. Data is gathered systematically—day, night, or during shift changes—and fed directly into the digital twin for analysis. Over time, this builds a complete and accurate picture of the site’s condition, supporting maintenance teams with reliable, up-to-date insights. You can learn more about this approach in Karelics’ overview of autonomous industrial monitoring.

How Digital Twins work together with Robotic dogs

A 3D Digital Twin becomes even more useful when it’s paired with data from autonomous robot dogs. As the robots make their rounds, they collect images, sensor readings, and environmental data and send it straight into the digital twin. There’s no need to sort files or manually upload anything—the information simply appears where it belongs in the 3D view.

For operators, this means one thing: everything is in one place. Instead of switching between camera feeds, inspection notes, or separate sensor dashboards, they can open the digital twin and see the latest data layered directly on top of the facility layout. If a robot captured a temperature anomaly or a small change in a production area, it’s easy to spot because it’s tied to a clear location in the model.

This combination also supports more accurate predictive maintenance. Regular, consistent inspections from the robots help reveal small trends—slowly rising temperatures, subtle movement in equipment alignment, or a recurring pattern in air quality readings. When that data is visualized in the twin, potential issues stand out earlier. For more on predictive maintenance, we also cover how IoT, AI, and digital twins work together in this article.

The result isn’t just better monitoring. It’s a smoother workflow for the people who rely on this information every day. Problems can be found sooner, maintenance can be planned more confidently, and teams spend less time gathering data and more time acting on it.

Benefits of autonomous industrial monitoring

Autonomous monitoring is becoming a practical addition to many industrial sites. It doesn’t replace existing systems or people, but it helps fill in the gaps—especially in tasks that need to be done repeatedly and with the same level of precision every time. The benefits tend to come from small improvements that add up over time.

1. Improved safety

With fewer routine walk-arounds, teams spend less time moving through busy or hard-to-navigate areas. It doesn’t remove risk entirely, but it does reduce the amount of physical exposure needed for regular checks.

2. Cost efficiency

Automated inspections can take over the time-consuming rounds that normally require several people. And when small issues are noticed earlier, it often prevents bigger disruptions that are more expensive to deal with later.

3. Higher accuracy and better anomaly detection

A robot repeats the same route in the same way each time. That consistency makes patterns easier to track and helps highlight gradual changes that might not stand out during occasional manual checks.

4. Centralized decision-making

When monitoring data comes from a variety of sources—sensors, systems, and robotic inspections—it’s helpful to have it gathered in one place. This gives teams a clearer overview without switching between multiple tools.

5. Scalability across facilities

Once an autonomous monitoring workflow is set up, it can be applied to other areas or additional sites with relatively small adjustments. This helps companies keep their monitoring practices aligned across different locations.

Industrial monitoring use cases

Solar plant monitoring

Tracking panel performance and environmental conditions over time.

Challenge

In a solar field, temperature variations and surface changes can influence output. Routine checks take time, and small deviations aren’t always noticed during manual rounds. Autonomous inspections help document these changes consistently, while the Digital Twin keeps the information organized so trends are easier to follow.

Impact

Teams gain a clearer view of how the site behaves throughout the day or across seasons, supporting more informed maintenance planning. To explore how a 3D Digital Twin could be applied in a solar plant environment, you can book a demonstration and see practical examples of the setup.

If you’d like to explore how this could fit into your own operations—or see a practical example of how the 3D Digital Twin works in environments like solar plants—you’re welcome to book a demo or reach out to our team for a closer look.

Equipment condition tracking

Monitoring pipelines, storage areas, and processing equipment.

Challenge

Temperature shifts, vibration changes, or unusual readings can develop gradually and may blend into normal routine noise. With autonomous inspections feeding structured data into the Digital Twin, these small variations become easier to spot and interpret.

Impact

Maintenance teams can investigate potential issues sooner and understand how conditions evolve across different parts of the site.

Machine & production line monitoring

Identifying small changes in machine behavior that affect quality or throughput.

Challenge

Busy production floors make it difficult to track minor fluctuations from run to run. Robots repeating the same inspection route help capture data consistently, and the Digital Twin highlights deviations that might otherwise go unnoticed.

Impact

This supports smoother production planning and helps teams decide when maintenance is needed rather than relying only on fixed schedules.

Bringing together a 3D Digital Twin and autonomous robot inspections creates a monitoring setup that is both consistent and easy to follow. The digital twin keeps all data in one place, while the robots add regular, structured observations that help show how conditions develop over time. It’s a straightforward combination that supports everyday work across different types of industrial sites.

Process Genius and Karelics approach this from two angles that complement each other: one provides the visual and data integration layer, and the other provides the tools for steady, repeatable inspection. Together, they offer a way to understand what’s happening on site without adding extra steps for the people who rely on that information.

If you’d like to take a closer look at how this approach works in practice, feel free to get in touch with us or book a demo whenever it suits you.

Digital Marketing & Business Specialist