Konecranes Machine Tool Service and its technology partner Process Genius Oy have joined forces

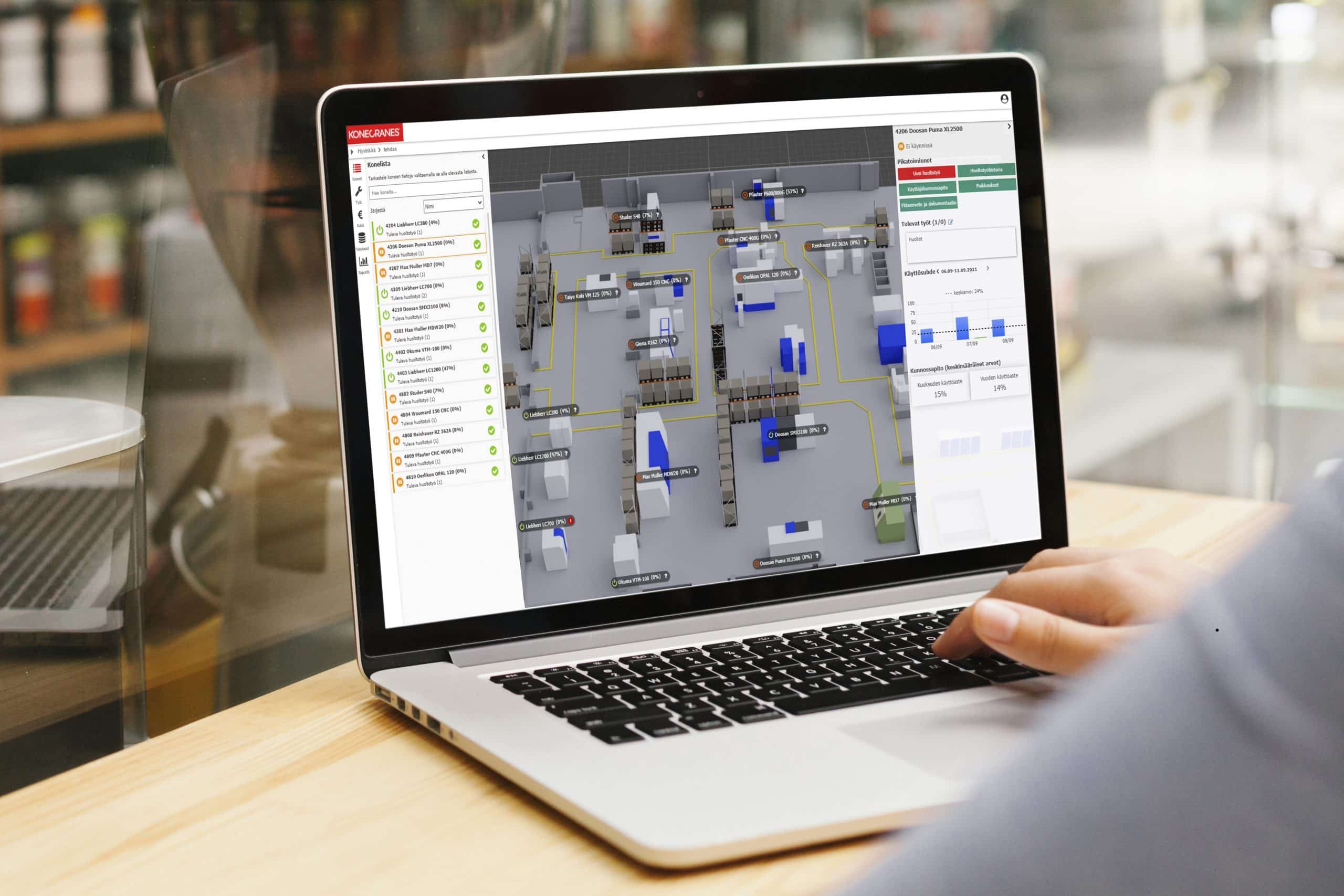

A revolutionary new feature – Get a complete production snapshot fast! An up-to-date production and maintenance snapshot enables fact-based production management.

The application has produced revolutionary results in operational use:

- Productivity increased by 30%

- Wasted hours have dropped by up to 80%

- Significant savings in electricity consumption; typically 3-25kW of unnecessary power consumption per machine/appliance during off-shift hours. At best, large factories have achieved annual savings in the megawatt class, when there are +50 machines in the measurement.

- Significant increase in the availability rate

The results are also quickly visible in practice, speeding up the day-to-day management of the factory and moving towards a LEAN mindset.

The app allows:

- faster flows

- making results and rewards transparent and visible to all

- visualizing waste

- idling of machines outside running hours-> standby, fault conditions and unnecessary auxiliary equipment or faulty machines can be shut down before they become energy wasters.

Other customer stories

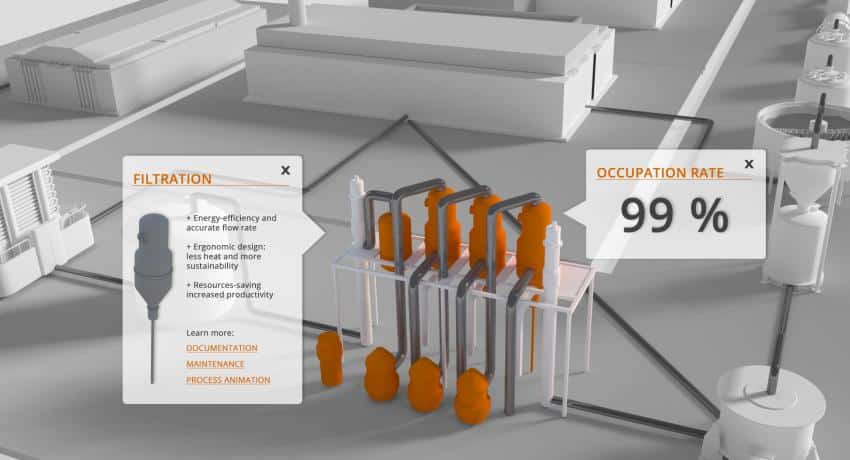

Pekotek: White Labeling allows Pekotek’s end customers to benefit from cost savings and predictive maintenance capabilities provided by the 3D Digital Twin

Taking day-to-day management processes to a new level – Konecranes Smart Factory

Working together to develop service business – Flowrox and Process Genius

All the information you need at one glance. One platform.

Want to know more about our solution for your organization? Please drop us a line and we’ll be in touch!