How Digital Twins solve OEM manufacturing challenges

This article looks at how 3D Digital Twins help OEMs solve everyday manufacturing problems — like poor visibility, stock issues, and slow service response. It shows how real-time data and connected systems make it easier to plan ahead, work better with dealers, and keep everything running smoothly. You’ll also see how a platform like Genius Core brings all the info together in one clear view.

Manufacturing has become more complex in recent years. Customer expectations are growing, supply chains are harder to manage, and products are becoming more advanced. For OEMs (Original Equipment Manufacturers), this means dealing with a wide range of challenges — from production efficiency to parts availability and service coordination.

One approach that’s starting to make a difference is the use of 3D Digital Twins — virtual models that reflect real-world products or systems. These models can help OEMs improve how they plan, monitor, and support their operations.

In this article, we’ll look at some of the most common challenges OEMs face today and how Digital Twin technology can support them in solving these issues.

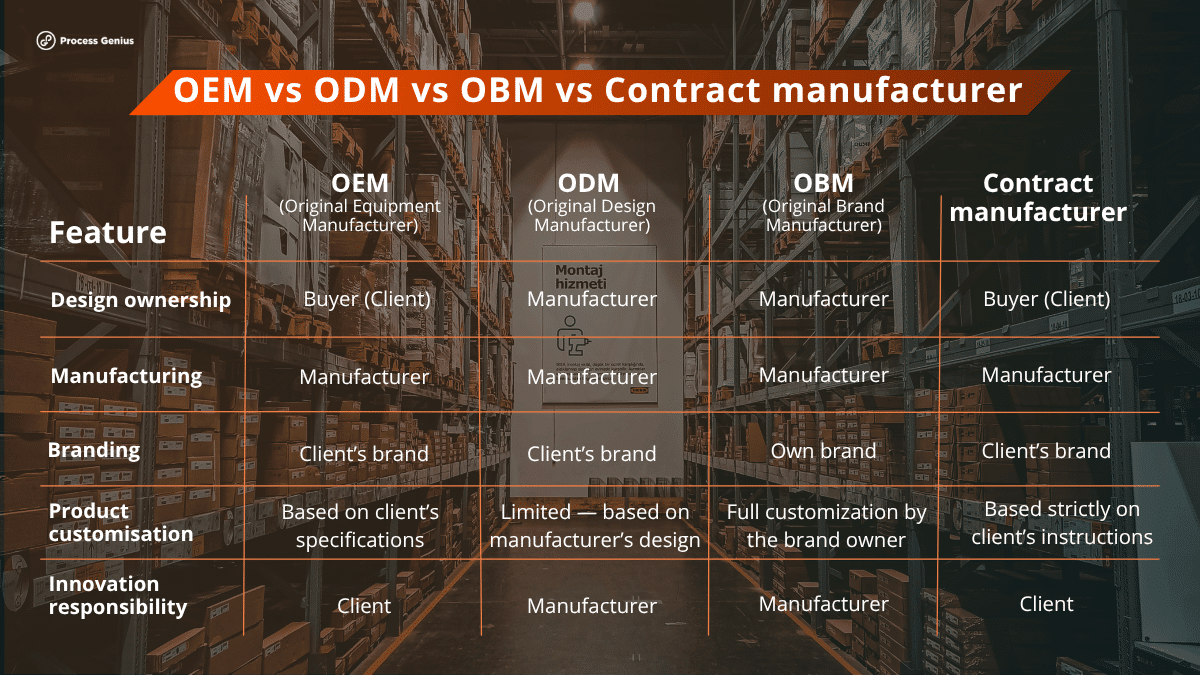

Before we move on to real-life examples and strategies, it’s helpful to go over a few key terms. What exactly is an OEM? How is it different from other types of manufacturers like ODMs or contract manufacturers?

OEM vs ODM vs OBM vs Contract Manufacturer

There are several types of manufacturers out there, and the terms can get confusing. Here’s a simple breakdown:

- OEM (Original Equipment Manufacturer): Builds products based on a buyer’s design and specifications. The buyer owns the design and branding.

- ODM (Original Design Manufacturer): Designs and makes products themselves, which other companies can rebrand. The manufacturer owns the design.

- OBM (Original Brand Manufacturer): Designs, makes, and sells products under its own brand. These companies handle everything from manufacturing to marketing.

- Contract Manufacturer: Makes products under contract for other companies. Usually has no involvement in design or branding — just follows instructions.

Even though you may not see their logos on the final product, OEMs are essential to how modern products are built and delivered.

Importance of OEM in Manufacturing

In most industries, it’s not practical (or efficient) for a single company to design, manufacture, and assemble every part of its product in-house. That’s where OEMs come in. They handle specialized production tasks — such as making electronic components, mechanical parts, or even full assemblies — so their clients can focus on product strategy and market delivery.

OEMs are especially important in automotive, aerospace, consumer electronics, and industrial equipment, where products rely on a wide network of suppliers and precision-built components.

OEMs play a key role in many industries. Here are a few examples:

- Automotive: Bosch manufactures parts like brakes and sensors used by car brands like BMW and Toyota.

- Electronics: Foxconn assembles products and components for companies like Apple and Dell.

- Industrial Machinery: Siemens produces components that are built into machines and systems used by other equipment manufacturers.

OEMs are also playing a growing role in the transition to smart factories and Industry 4.0. As manufacturing becomes more digital and data-driven, OEMs are adopting technologies like IoT sensors, real-time tracking, and automation to improve efficiency and transparency.

These changes aren’t just about keeping up with trends — they’re about meeting new expectations from partners and customers who want greater visibility, flexibility, and reliability throughout the supply chain.

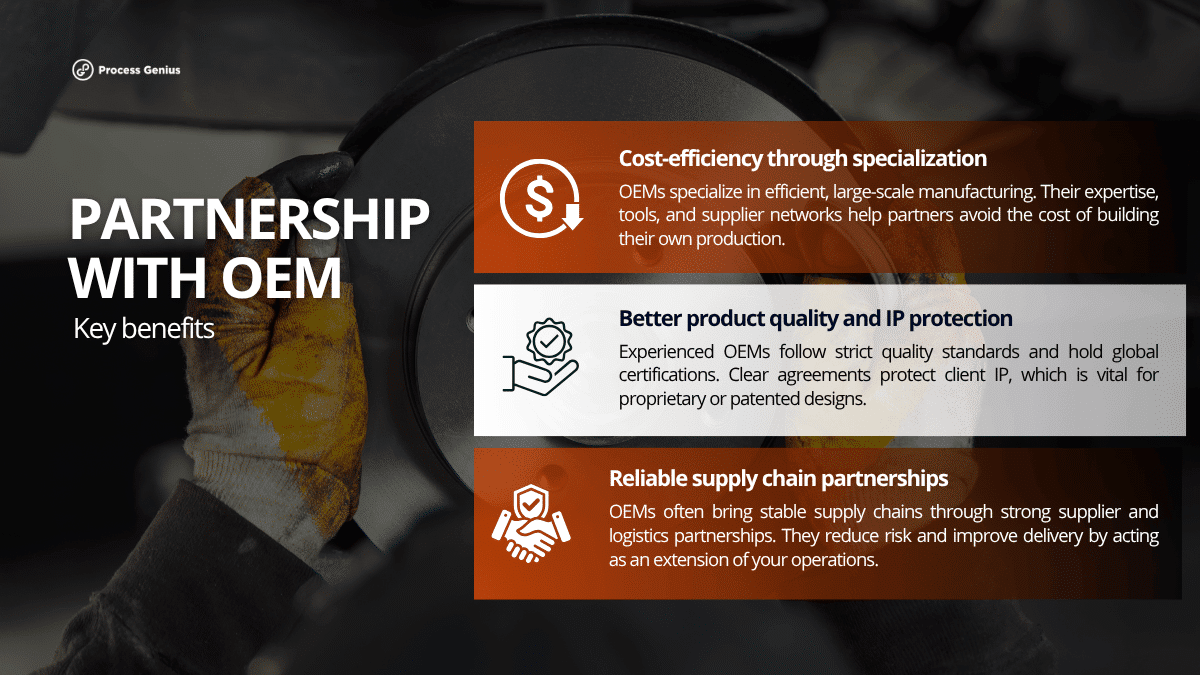

Benefits of working with OEM Manufactures

For many companies, partnering with an OEM is not just a cost-saving decision — it’s a strategic move. Whether you’re launching a new product or scaling an existing one, working with an experienced OEM can simplify your operations and help you stay competitive.

Here are some of the main benefits OEM partnerships bring to the table:

1. Cost-efficiency through specialization

OEMs are set up to do one thing well: manufacture. Because they specialize in a particular type of product or component, they often have the tools, processes, and supplier relationships needed to produce efficiently at scale. This allows their partners to avoid the costs of setting up their own production lines.

2. Better product quality and IP protection

Experienced OEMs follow strict quality control standards and often have certifications that meet global manufacturing requirements. They also work under clear agreements that protect the client’s intellectual property (IP) — especially important when the product design is proprietary or patented.

3. Reliable supply chain partnerships

OEMs often have long-standing relationships with material suppliers and logistics providers. This means they can often offer more stability, especially when supply chains are tight or disrupted. A reliable OEM can act as an extension of your own operation, reducing risk and improving delivery consistency.

While OEMs can offer real advantages to their partners, they also face growing complexity behind the scenes. Managing quality across multiple product lines, coordinating supply chain partners, and maintaining efficiency at scale aren’t simple tasks. In fact, many of the strengths that make OEMs attractive — like flexibility, speed, and specialization — can also create pressure on their internal operations.

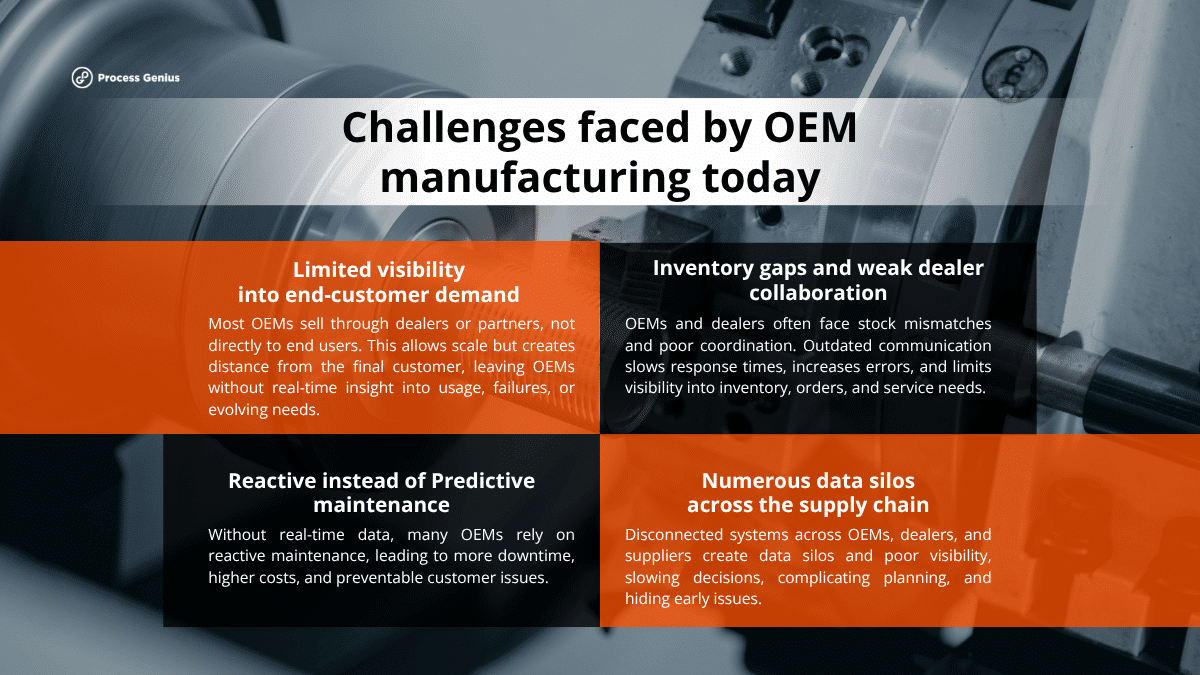

Top challenges faced by OEM manufacturing today

1. Limited visibility into end-customer demand

Most OEMs don’t sell directly to end users. Instead, they rely on a network of dealers, distributors, or brand partners. While this setup works well in terms of scale, it also creates distance from the final customer. As a result, OEMs often lack real-time data about what’s being used, what’s breaking down, or what customers actually need next. This lack of visibility makes it hard to plan inventory, forecast demand, or respond to service issues quickly.

2. Inventory misalignment across dealer networks

Another common issue is dealer stock misalignment. OEMs may ship out parts or products, but they don’t always know what their dealers have on hand — or what they’re running low on. Dealers, meanwhile, often struggle to keep just the right amount of stock without over-ordering or running out.

3. Reactive instead of Predictive maintenance

Many OEMs still rely on reactive maintenance — waiting until something breaks before fixing it. Without real-time machine data or service histories from the field, it’s hard to anticipate issues before they become problems.

This approach often leads to increased downtime, higher repair costs, and dissatisfied customers — especially when problems could have been prevented with earlier action.

One way OEMs are starting to move beyond this model is by using 3D Digital Twin technology. For a deeper look at how IoT, AI, and Digital Twins work together in this context, check out this guide from Process Genius.

4. Poor collaboration with dealers

Good coordination between OEMs and their dealer networks is essential — but it’s often harder than it should be. In many cases, communication still relies on outdated systems, spreadsheets, or email chains. This slows down workflows, increases the risk of errors, and makes it difficult to respond quickly to changes in demand or service needs.

A major pain point is the lack of visibility into production and delivery status. Dealers often don’t know when orders will be completed or shipped — and OEMs don’t always have a clear view of stock levels or service requests on the dealer’s side.

Tools like Genius Core can help solve this by offering real-time production tracking. When both sides can see what’s happening — from order progress to stock movement — communication becomes faster, clearer, and more accurate. This reduces delays, improves planning, and builds more trust between partners.

5. Data silos across the supply chain

OEMs often work with a mix of disconnected systems — one for inventory, another for production, and others for service or logistics. On top of that, dealers and suppliers may use their own tools, creating even more layers of separation.

This fragmentation leads to data silos, where important information is trapped in different systems. It becomes difficult — sometimes impossible — to get a clear, real-time picture of what’s happening across the full value chain. That lack of visibility slows down decision-making, complicates planning, and makes it harder to spot and solve problems early.

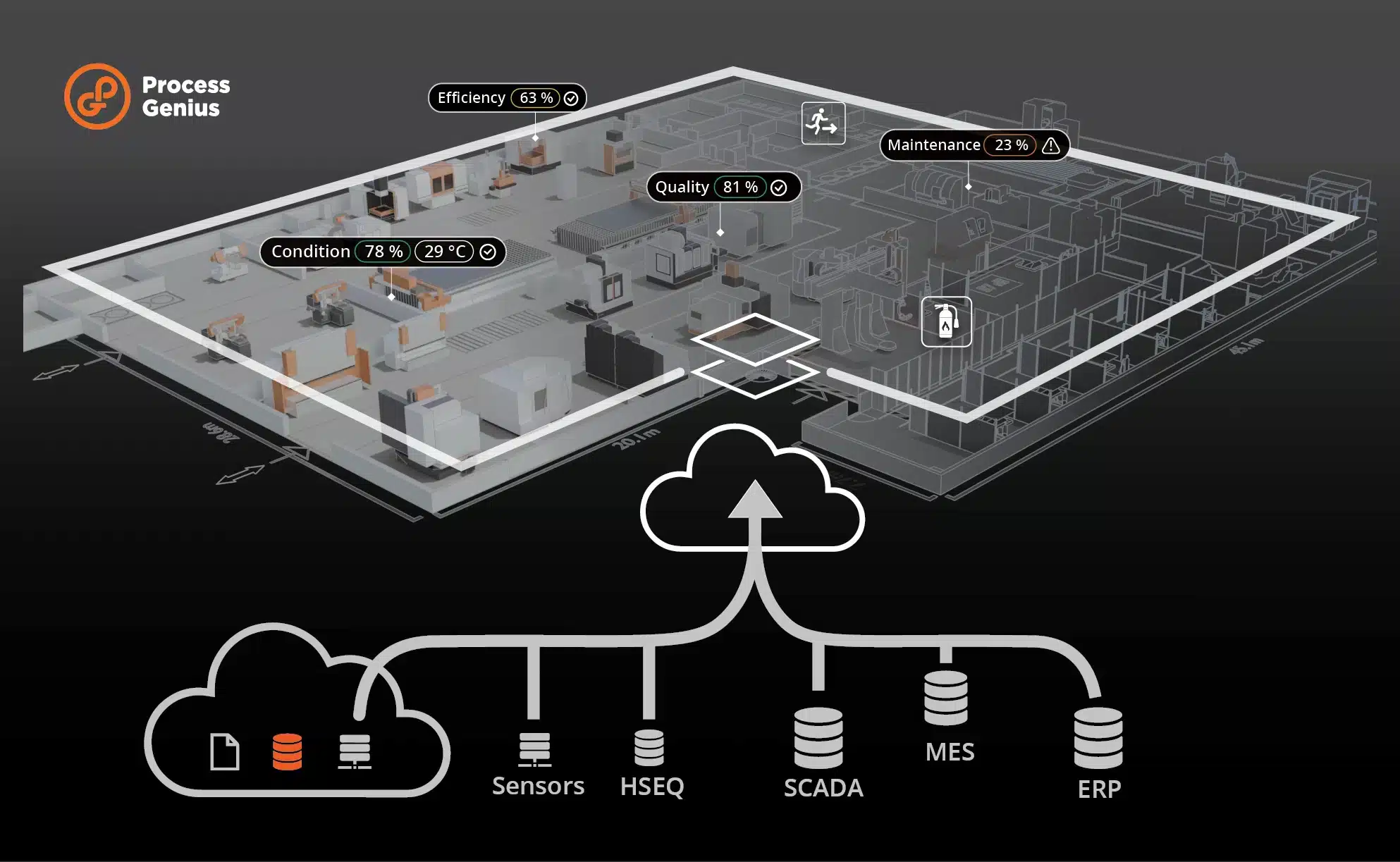

A solution to this is using a platform like Genius Core, which can integrate data from multiple systems into one shared environment. Through its data layout functionality, users can easily organize and access the information they need — whether it’s production status, inventory levels, or service requests.

Instead of jumping between tools or chasing down updates, teams can work from a single source of truth — improving both speed and clarity across departments and partners.

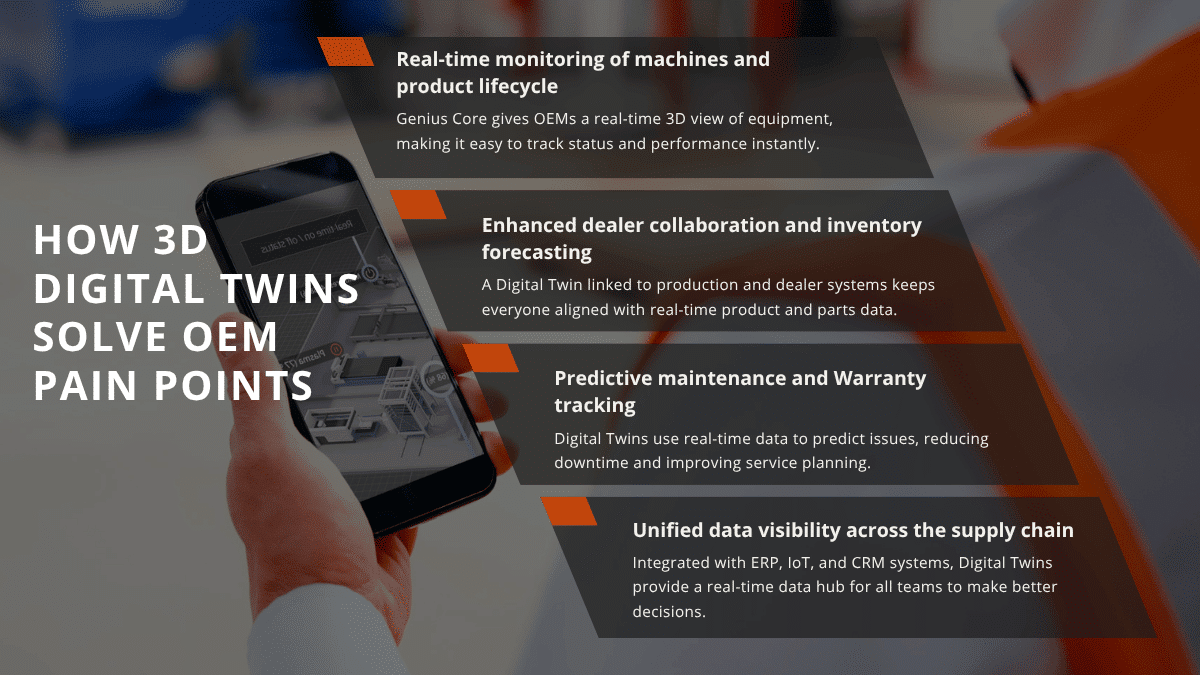

How 3D Digital Twins solve OEM pain points

As OEMs work to stay competitive in a complex, fast-moving manufacturing environment, Digital Twin technology offers a way to tackle many of the core challenges they face.

1. Real-time monitoring of machines and product lifecycle

With a Digital Twin platform like Genius Core, OEMs can monitor machines and systems in real time . The system creates a 3D visual model of the equipment, connected to live data streams, so teams can track status, performance, and usage at a glance.

This kind of remote monitoring makes it possible to detect anomalies early, follow the product lifecycle more closely, and improve service response times. For example, operators can spot changes in temperature, pressure, or operating speed — all without being physically present on-site.2.

2. Enhanced dealer collaboration and inventory forecasting

With a Digital Twin connected to production and dealer systems, OEMs can share up-to-date information about product status and part availability. It’s a practical way to align everyone — from factory to service center — around the same, current data.

3. Predictive maintenance and Warranty tracking

Digital Twins support a shift from reactive to predictive maintenance by using real-time data and performance KPIs to forecast issues before they happen. his helps OEMs plan service ahead of time, reduce downtime, and manage warranty claims more effectively.

4. Unified data visibility across the supply chain

By integrating with systems like ERP, IoT platforms, CRMs, and maintenance software, Digital Twins become a central hub for decision-making. Everyone — from engineers to service teams to partners — can work from the same source of real-time data.

Digital Twins support a shift from reactive to predictive maintenance by using real-time data and performance KPIs. This helps OEMs plan service ahead of time, reduce downtime, and manage warranty claims more effectively.

Implementation tips for OEMs

Introducing Digital Twin technology into an OEM operation doesn’t have to mean overhauling everything at once. In fact, starting small and building gradually is often the most effective path. Below are a few practical steps OEMs can take to begin integrating Digital Twins into their processes — with minimal disruption and maximum long-term value.

Step 1: Start with a limited pilot

nstead of trying to digitize everything at once, focus on one area — like linking IoT sensor data on a specific machine or product line. This kind of pilot project allows you to test your approach, prove the value of the system, and learn what works before scaling up.

It’s also a good way to get early feedback from users on both the technical side and within service or support teams. It also helps you identify any technical or data integration issues early on — before committing to a full rollout.

A focused pilot is a great way to gather early feedback from internal teams, especially those in engineering, field service, or product support. It also builds confidence across departments by showing practical, real-world results.

If you’re considering this step, you can also explore a test drive option with our specialists to see how a Digital Twin pilot could work for your use case. It’s a low-risk way to validate the concept before moving forward.

Step 2: Connect key systems Like ERP and DMS

For a Digital Twin to work effectively, it needs to draw information from different parts of the business. Start by connecting your core systems — like your ERP (Enterprise Resource Planning) platform and DMS (Dealer Management System). This allows data to flow between departments and across your partner network, creating a more complete and useful picture of production.

Step 3: Align your data-sharing strategy with dealers

A successful Digital Twin isn’t just about internal data — it’s also about better collaboration. Talk to your dealers about what information they need access to (like service alerts, inventory levels, or real-time order updates), and what they can share back with you (like service history or customer feedback).

This data-sharing alignment improves visibility, reduces friction, and supports more proactive service and support across the board.

With Genius Core, you don’t have to give everyone access to everything. The platform allows you to restrict access to specific data based on user roles. As the OEM manufacturer, you can create and manage these roles yourself — giving a particular dealer access only to the products they’re responsible for, or grouping several dealers together and assigning them shared visibility into a group of products.

This kind of control ensures data stays secure, while still making the right information available to the right people — improving trust and collaboration across your network.

Step 4: Choose scalable, flexible software

Look for a Digital Twin platform that fits your size and goals — but also one that can grow with your needs. Solutions like Genius Core offer real-time 3D modeling, IoT integration, and compatibility with ERP and CRM systems. Make sure the platform can adapt to different product types and support multi-location deployments if needed. That flexibility is key to ensuring your setup continues to deliver value over time.

With Genius Core, you can also start with a starter package and scale up as needed. For example, when you need to monitor more assets or add complexity, you can upgrade to a more advanced plan — which includes the ability to place and manage more Points of Interest (POIs) in your 3D environment.

This ensures your investment supports long-term growth, not just short-term goals.

Digital tools for real-world OEM challenges

OEMs today operate in a fast-changing environment. Rising customer expectations, complex supply chains, and growing product demands all require more visibility, better coordination, and smarter decisions.

That’s where Digital Twin technology comes in. It’s not just a trend — it’s a practical tool that helps solve real challenges: from improving maintenance planning and dealer collaboration to streamlining data across production and service.

By starting small, integrating the right systems, and choosing a scalable platform like Genius Core, OEMs can take confident steps toward a more connected, efficient operation.

Contact us to learn how you can bring Digital Twin technology into your OEM workflow — from predictive maintenance to real-time supply chain optimization. Whether you’re exploring a pilot project or looking for a full platform rollout, our team is here to help.

Digital Marketing & Business Specialist