Working together to develop service business – Flowrox and Process Genius

Cooperation boosts device manufacturer’s transition towards service business

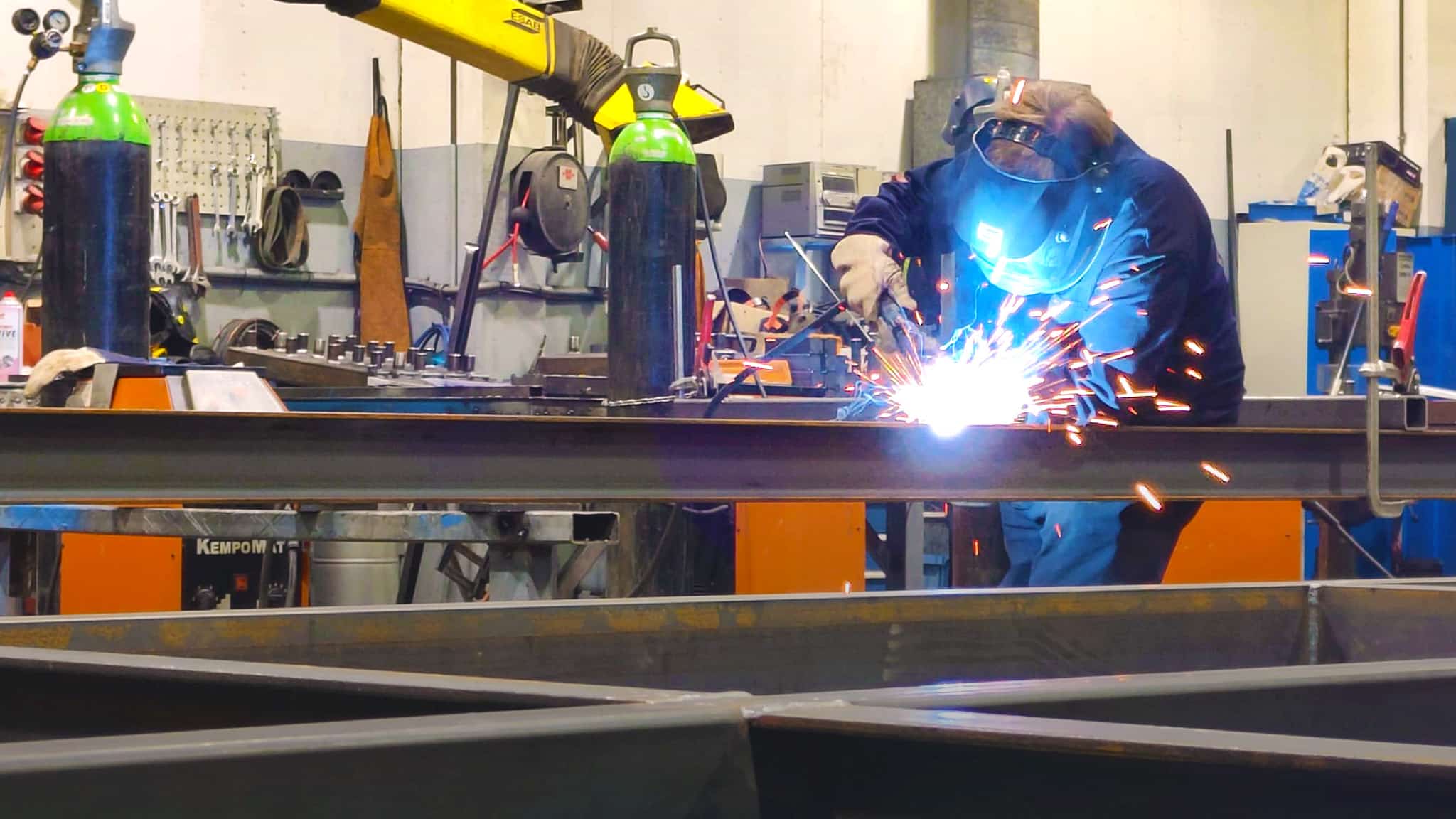

Flowrox (from 11.01.2021 part of the Neles Group) manufactures and sells flow control and management devices for demanding industrial applications in over 50 countries. The Process Genius product family has helped with customer, distributor and staff training, distribution of technical sales materials and product development. The solutions developed in cooperation will also seek to create a new kind of business – moving from the traditional role of equipment manufacturer towards a service business.

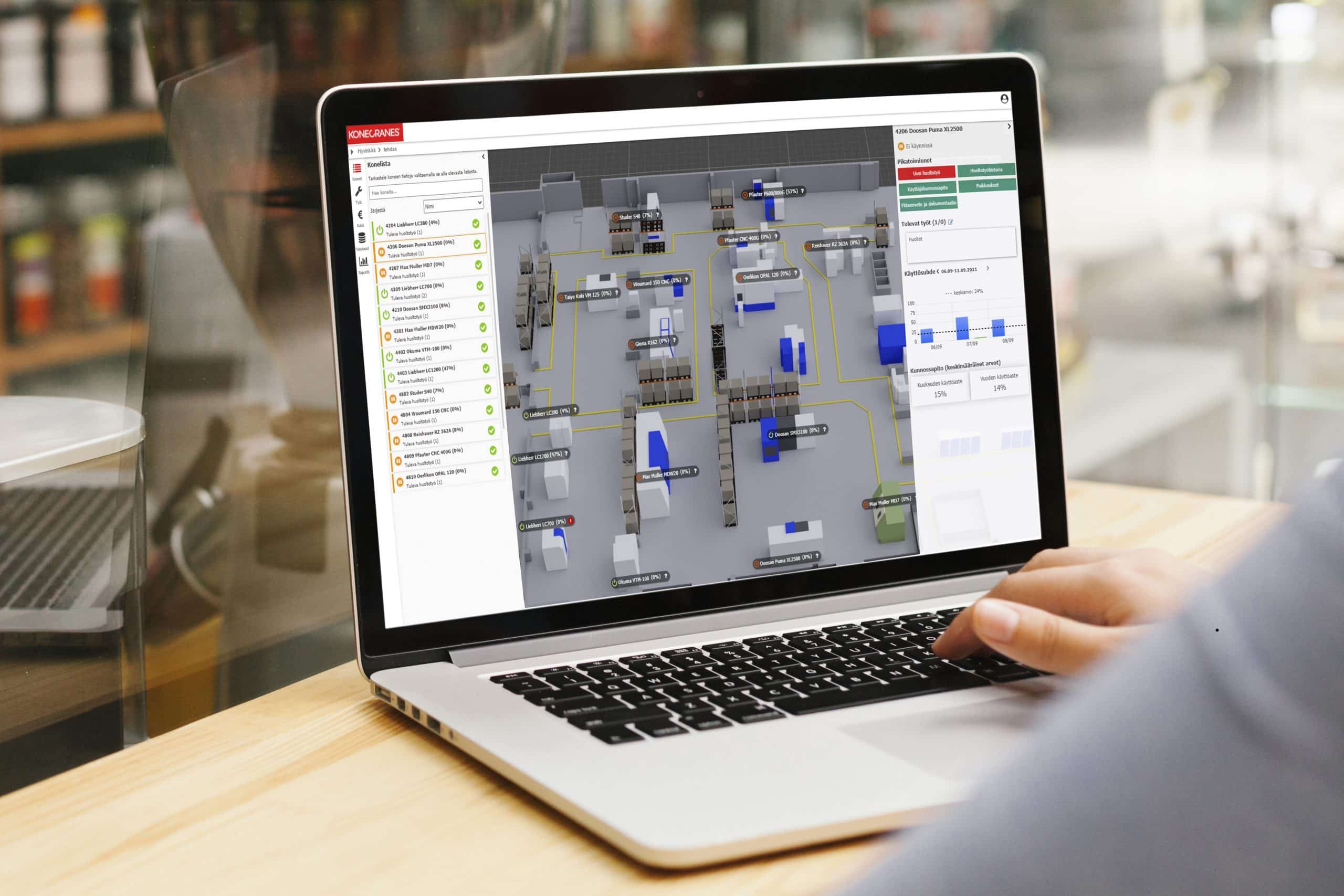

Digital twin -platform is streamlining the Flowrox sales network

The collaboration between Flowrox and Process Genius started in 2012 with the Flowrox Pro application, developed on the digital twin platform to streamline the distribution of sales-related material to the sales network. They wanted all the information to be easily found in one place. In the application, Flowrox products are illustrated in a 3D-modelled customer process environment and sales material related to the products can be found in the product information section. The application has helped to increase the sales network’s knowledge of customer processes and the suitability of Flowrox products for different sub-processes.

AR and VR technologies to support education and marketing

Flowrox has been developing Augmented Reality (AR) and Virtual Reality (VR) solutions since 2015. AR will help train on the operation and maintenance of equipment, VR will act as product demonstrators.

AR:llä voimme jatkossa tuoda tietoa suoraan asiakkaan toimintaympäristöön. Tulevaisuudessa esimerkiksi huolto-ohjeet voi esittää mobiililaitteissa lisätyn todellisuuden (AR) avulla, tai HoloLens-tekniikalla heijastaa suoraan huoltomiehen suojakypärän visiiriin. VR:ää olemme käyttäneet messuilla tuotteidemme esittelyyn kaivosympäristössä. Process Genius auttaa meitä olemaan näiden teknologioiden suhteen alan edelläkävijä.

Digital twin supports Flowrox’s product development

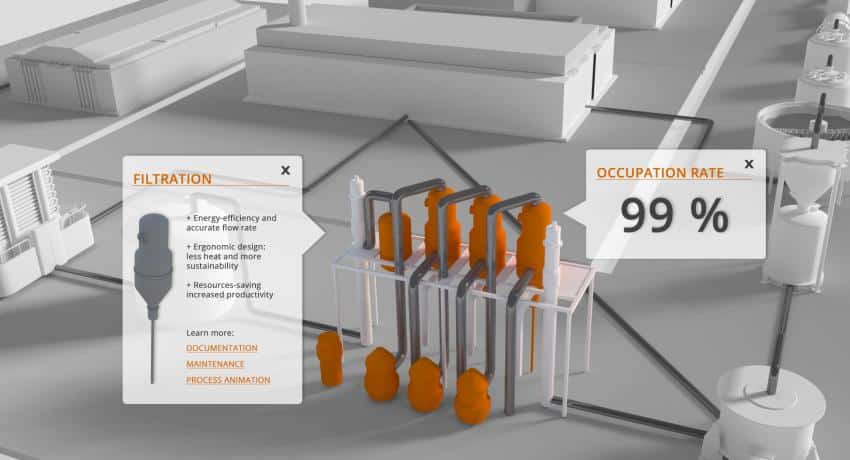

Our latest collaboratively developed Digital Twin -solution is the Flowrox Malibu™ user interface, designed on top of the Genius Core™ platform, which gathers and analyses data with sensors from Flowrox’s devices. The user interface is based on 3D modelling of the real customer environment and the processing and visualisation of equipment data.

Asiakkaamme ulkoistavat tehtaidensa huoltotoimintoja ja laitekohtaisen teknisen osaamisen taso voi vaihdella paljonkin eri alihankkijoilla. Malibu tukee ja helpottaa heidän toimintaansa tuomalla laitteisiin liittyvän tiedon helposti ja intuitiivisesti saataville, oli kyse laitteiston kunnon seurannasta tai huoltotoiminnoista.

Sensors connected to equipment and processes are connected to the internet, so Malibu can be used to view equipment remotely and provide remote operational support to the customer. Sensor data provides information on the conditions under which the equipment is operating, enabling analysis of equipment durability and spare parts consumption. The analyses provide the customer with valuable information on, for example, the operation of the equipment and the need for maintenance. In addition to equipment monitoring, Malibu can optimize the operation of equipment and surrounding processes.

Asiakkaalla voi olla prosessidatan käsittelyyn useita eri järjestelmiä, jotka usein keskustelevat eri protokollilla. Malibu yhdistää eri järjestelmistä saatavan tiedon ja jäsentää prosessissa syntyvää tietoa esimerkiksi tehtaan johdolle tai käyttöhenkilöstölle.

All the information you need at one glance. One platform.

Want to know more about our solution for your organization? Please drop us a line and we’ll be in touch!