Taking day-to-day management processes to a new level – Konecranes Smart Factory

Eurometal 28.10.2021:

Konecranes Smart Factory takes day-to-day management processes to a new level

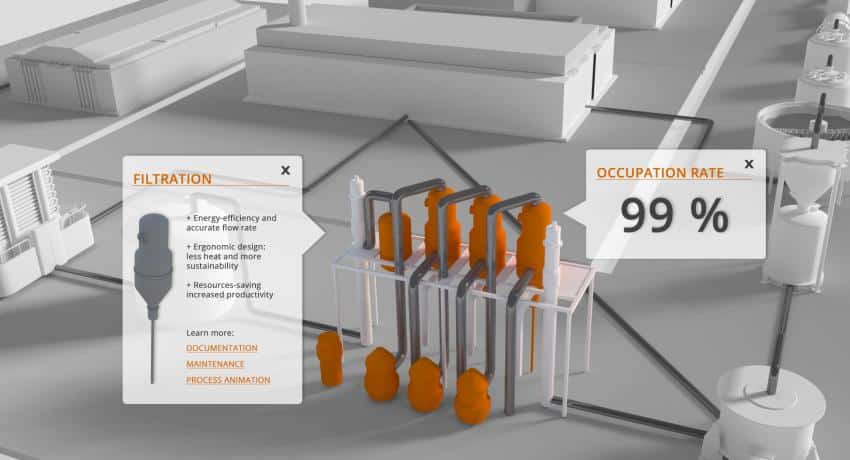

Konecranes Smart Factory is an accurate three-dimensional digital replica and model (Digital Twin) of a physical factory, allowing real-time operations and processes in the factory to be viewed from a web browser or mobile device. The Smart Factory, implemented with technology partner Process Genius Oy, collects important data from various software, hardware and sensor interfaces on the platform and provides a 24/7 snapshot of the factory’s production and maintenance. From the visual model, users can see instantly key information about production and maintenance. The Smart Factory solution improves data transfer between the plant’s staff in a number of ways, and also between customers, service providers and partners.

Day-to-day management requires the most real-time information possible

Konecranes had been following the world of machine tools for almost 25 years, and there was a clear change in what customers, regardless of the size of the company, wanted from their service providers. In recent years, questions had also arisen repeatedly, asking: “How can we visualize production?” or “How can digitalization be seen at Konecranes?”

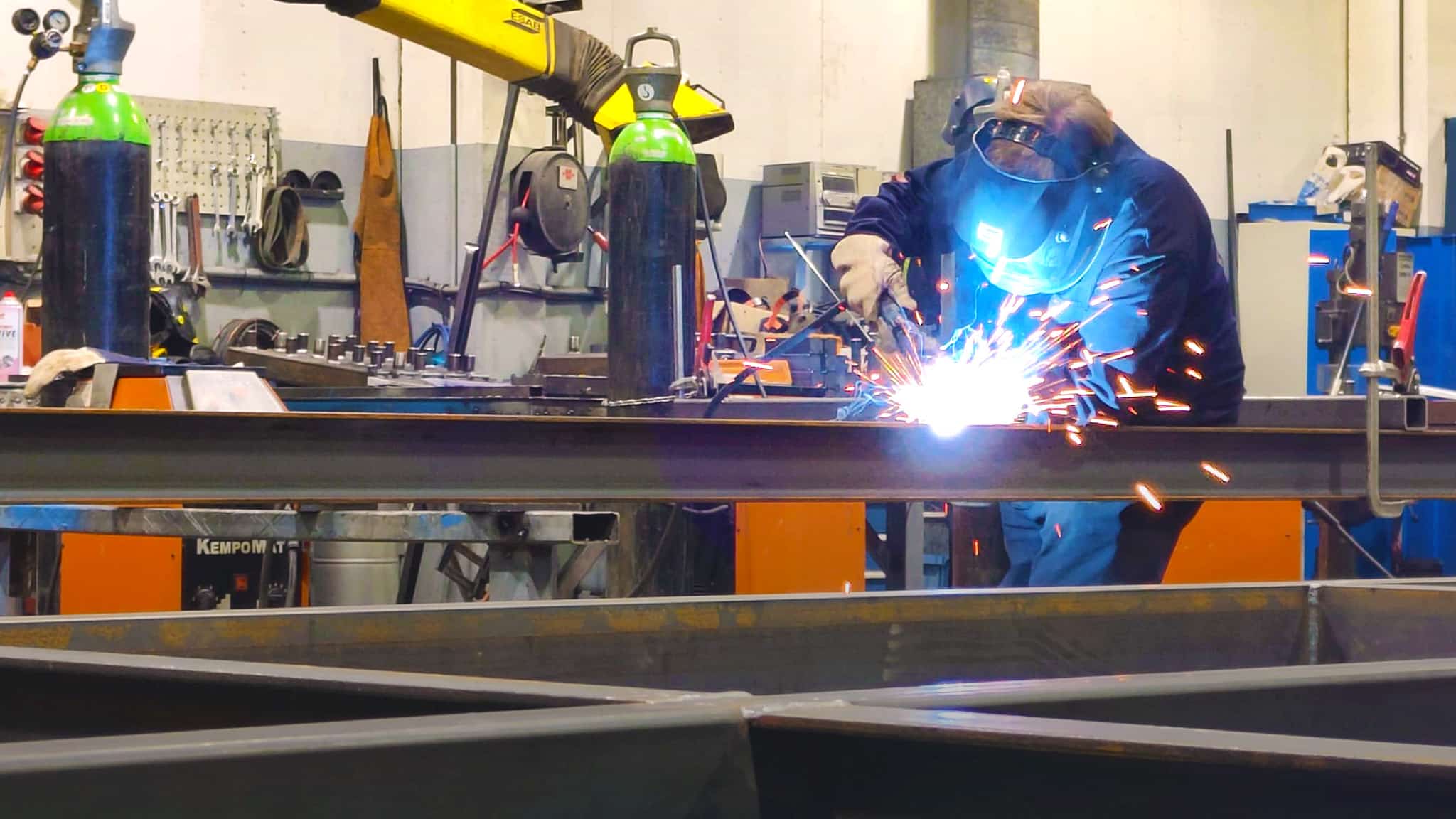

Maintenance is no longer a matter of servicing machines once a year and repairing them in between. There are machines in many age groups in Finland, and there is a desire to monitor their status wherever they are. Up-to-date information of what’s going on in the workshop is crucial for daily management.

Mechanical workshops have to develop as the software and machinery also develop. Equipment produces a lot of data, and there can be several data sources in the same factory. In the early stages of the project, Konecranes asked its customers if they had any systems in place to make use of all this data, and how they could use it in their business.

It turned out that no one had just one system in place, but all had to use a number of different systems to gather information about what was happening in their own plant. In addition, there were many different needs at different levels of the factory. There were also different digital twins already in use and different portals, but no one had a complete picture available in one place.

“Nowadays, collecting information about the machinery and equipment used in the production process is very important. This acts as a starting point for investigating production methodologies with new tools such as artificial intelligence. I see that the data collected and the information it provides can be used to improve efficiency and gain a competitive advantage in the market.”

Production and maintenance operations in real time on the 3D Digital Twin platform

Konecranes Smart Factory is a service package built on a smart factory platform that helps you manage your daily production and maintenance operations easily and efficiently. From a production point of view, important information on machine downtimes and their duration is obtained. In terms of overall efficiency, it is important to address the causes and causes of major production disruptions. Examples include equipment malfunction, machine failure, configuration, measurements, user maintenance, material shortages or logistical problems. The aim is to make efficient use of the data flow in a production plant, where the daily activities can be managed using the available data.

According to Jani Akkila, CEO of Process Genius Oy, Konecranes and Process Genius have brought a combination of digital and substance knowledge to the market that has never been done before. Process Genius has systematically developed its Digital Twin platform, which Konecranes has enriched with its experience as a substantive expert.

Konecranes has brought real and state-of-the-art experience to the development of the platform. The Konecranes Smart Factory application combines efficient maintenance and production with the latest 3D Digital Twin platform.

Productivity has increased significantly over the six-month monitoring period

“An up-to-date snapshot of production and maintenance has enabled production management based on facts at Konecranes plant in Hyvinkää. The application has produced good results in operational use, and productivity has increased significantly during the six-month follow-up period,” says Tuomas Patanen, Plant Manager at Konecranes’ component factory.

“The app has also helped us to catch up on lost hours. In practice, waste hours were caused by things like set-up times, waiting times, minor alarms and other production disruptions. Today, we can get to the source of wasted hours and, where possible, we can reduce wasted periods and make improvements to processes,” Patanen explains.

The utilization rate of the machines has increased significantly, and the application allows us to validate whether the hours planned for the job are on target. Konecranes Smart Factory enables better monitoring of the factory, and we can easily find out what’s happening in the factory. This allows us to react more quickly to, for example, why the machine has stopped. The best thing is that the app is available on your phone, for example, which allows remote monitoring in a completely different way to what you are used to.

Other customer stories

Pekotek: White Labeling allows Pekotek’s end customers to benefit from cost savings and predictive maintenance capabilities provided by the 3D Digital Twin

Working together to develop service business – Flowrox and Process Genius

Process Genius models Mecmetal’s concrete product machine into a digital twin

All the information you need at one glance. One platform.

Want to know more about our solution for your organization? Please drop us a line and we’ll be in touch!