Digital Twin to Give You Confidence through Control.

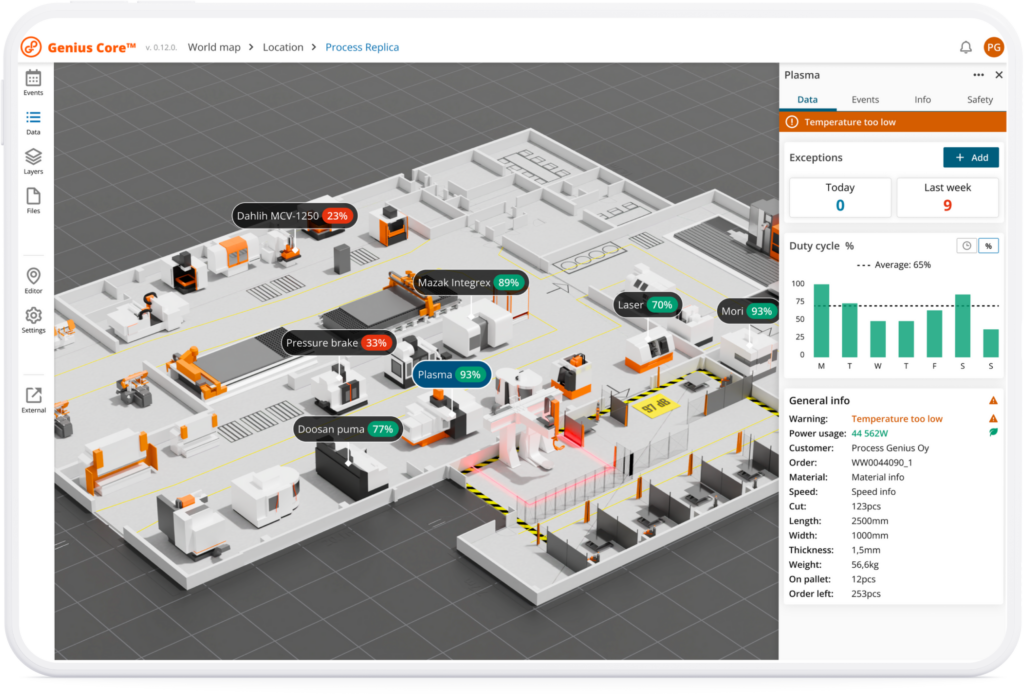

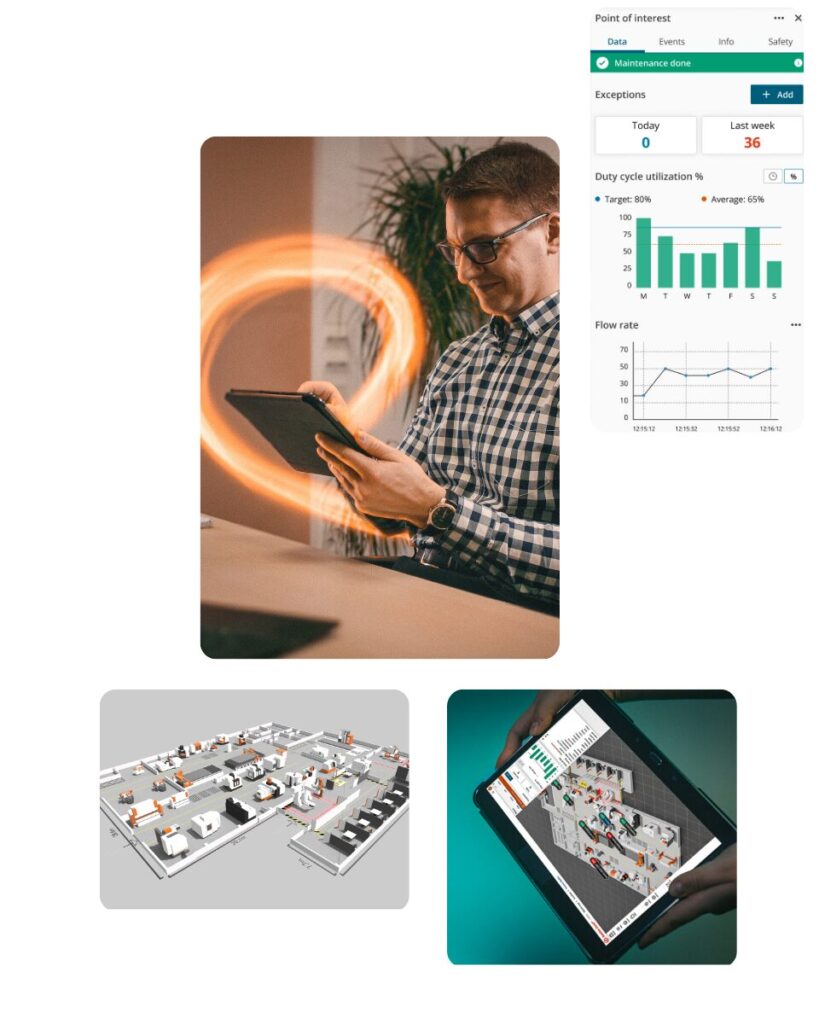

Genius Core 3D Digital Twin provides industrial manufacturers and process-focused industries with a fully configurable digital twin of their facilities. This gives you complete, real-time visibility over maintenance needs, safety, and operational efficiency from anywhere in the world.

Supercharging the biggest players in manufacturing and process industries

Your partner against data noise

Genius Core tackles the critical issue of digital noise in industrial processes, where hundreds of systems and sensors combine, making it extremely difficult to keep track of deviations in processes, maintenance, safety alerts, and malfunctions. The platform centralizes all data from equipment in a 3D visualization on both overview and facility levels, and all critical information can be accessed in real-time. Operators can also set up their digital twin without external help from external consultants.

Up to 30% improvement in production efficiency

Dealing with the overwhelming amount of data noise from various industrial systems and inputs shouldn’t be an everyday occurrence for you. Monitor and make decisions with confidence based on complete situational awareness anywhere, anytime.

Save 50 000 minutes every day

Managing day-to-day operations of your factory is a challenging job, and the tools used in it shouldn’t make it harder. With our platform, you can quickly see the information that matters most for your role in one easy-to-use platform.

Reduce waste and equipment downtime

Don’t let production downtime, quality issues, energy consumption and emissions, and wasted materials come to you as a surpise. With our 3D Digital Twin platform, you can instantly see bottlenecks in your production and what’s wasting your resources. With real-time data, you can react quickly to issues in your productions, reduce waste, and improve your processes.

No one knows your factory better than you do – Easily configure the platform to match your production needs and goals

Configurablity is the center of Genius Core’s latest feature set. Industrial professionals can set up their facility using their own data and 3D models and connect data streams directly to a single interface.

Watch our webinar recording: Transforming Data Noise into ROI

You have to be a genius to deal with the massive amounts of “data noise” in factory data today, and be able to turn it into actionable information. In today’s dynamic environment, companies must utilize AI and machine learning. Many insightful things follow from their use, but their use also adds disturbing data noise.

Join us for an insightful webinar where we discover how to transform this data noise into concrete actions and ROI with our esteemed AI, Machine Learning, and industrial digitalization guest experts from Bosch, Silo AI and Gofore.

Efficiency across different industries

Customer stories

Konecranes

Konecranes Smart Factory is a digital twin that takes daily management processes to a new level.

Stora Enso

Thanks to mill digital twins, the daily ERP of factories has been taken to a new level.

Snellman

Data visualisation enables cost savings and real-time monitoring of production processes at Snellman.

Ready to see Genius Core in action on your premises?

Book a free demo with us where our experts can demonstrate how Genius Core can work on your premises and add real value to your operations!