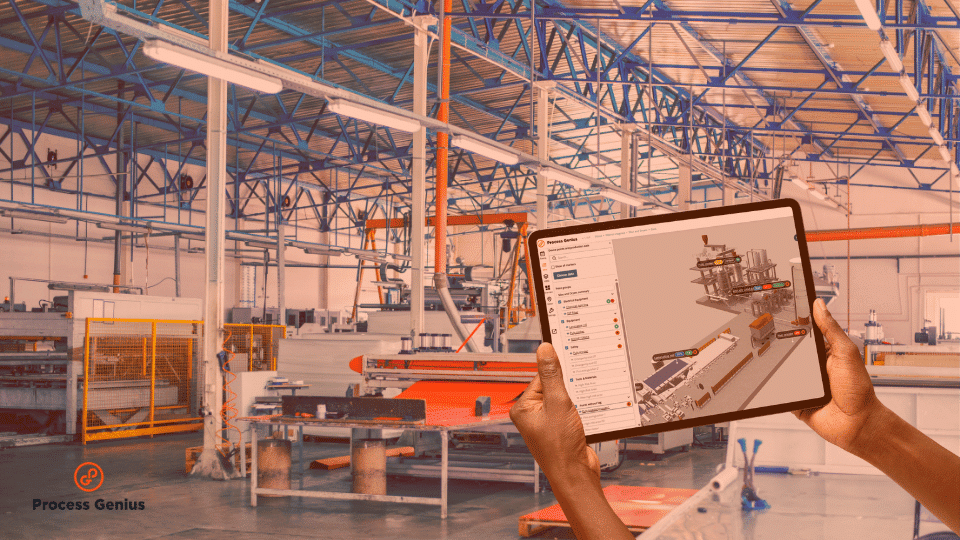

Supercharged Display Layer

Our 3D Digital Twin platform lets you easily integrate fragmented real-time data via API, configure it yourself, and visualize everything in one place. It cuts through the noise to deliver clear insights—showing what’s happening and what’s next.

Supercharging the biggest players in the manufacturing and process industries

Your partner in industrial solutions

Our vision is to put humans back in control

You have to be a genius to deal with the massive amounts of “data noise” in factory data today, and be able to turn it into actionable information. Process Genius is named after these heroes, who are responsible for solving challenges, relying on the sometimes overwhelming sea of industrial inputs and systems.

Process Genius helps you to get the situational awareness you need to make confident decisions. Our experience has been built up in close cooperation with leading companies in the manufacturing and process industries, using our 3D Digital Twin expertise for more than 10 years.

This is what we do

Industrial Digital Twin excellence

Why the biggest ones in the industry choose us

Lead with confidence and data-driven decisions

Eliminating delays in decision-making

Save up to 50 000 minutes every day

Managing day-to-day operations of your factory is a challenging job, and the tools used in it shouldn’t make it harder. With Genius Core, you can quickly see the information that matters most for your role in one easy-to-use platform.

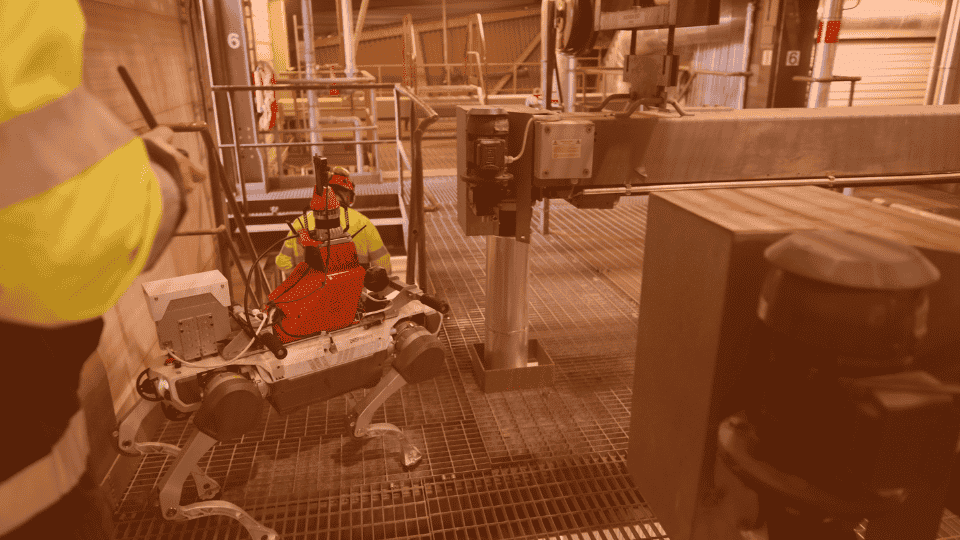

HSEQ made simple

Reduce waste and equipment downtime

Don’t let production downtime, quality issues, energy consumption and emissions, or wasted materials come to you as a surprise. With Genius Core, you can instantly see bottlenecks in your production and what’s wasting your resources.

Always up-to-date

Receive safety alerts in 5 minutes instead of waiting a week

Safety and security shouldn’t be a matter of long waiting times to figure out what happened or avoiding accidents out of pure luck. Our Digital Twin platform allows you and your workers to receive accurate, real-time safety alerts and views so you can monitor and act quickly on accidents, near misses, and other safety concerns. Prevent accidents and ensure the safety of workers, suppliers and customers in your factory.

For data-driven decision-making

Up to 30% improvement in production efficiency

Dealing with the overwhelming amount of data noise from various industrial systems and inputs shouldn’t be an everyday occurrence for you. With an easy access to real-time data, you can react quickly to issues in your production. Our solution helps you to monitor and make decisions with confidence based on complete situational awareness anywhere, anytime.

Efficiency across different industries

Customer stories

Konecranes

Konecranes Smart Factory is a digital twin that takes daily management processes to a new level.

Snellman

Data vizualisation enables cost savings and real-time monitoring of production processes at Snellman.

Expert insights

Discover the stories and trends shaping the future of industry

All the information you need at one glance. One platform.

Want to know more about our solution for your organization? Please drop us a line and we’ll be in touch!